What Are Some Examples of Structural Elements?

Many clients confuse structural elements1 with visual design2 or material labels.

**Structural elements1 are core components that resist forces, support loads, and ensure system stability2.

These appear in engineering frames, technical writing1, and persuasive texts2.

I’ve seen errors when clients mix up load-bearing parts or skip proper text structure. Yet, a clear structure prevents issues—and saves time and cost. Whether sourcing custom CNC parts1, ISO-certified casting parts2, or writing manuals, structure matters.

Let’s dive into different types of structural elements across fields.

What Are the 4 Structural Elements?

Beams, columns, trusses, and slabs form the backbone of structural design1.

They appear in construction, machines, and fabricated assemblies. Each serves a specific load-bearing function2.

| Structural Type | Description | Application Examples |

|---|---|---|

| Beam | Handles bending stresses | BridgeWeb, CNC frames |

| Column | Carries vertical compressive loads | BigRentz, warehouse support |

| Truss | Triangular structure for stability | Structural101, roofs |

| Slab | Flat load-distribution surface | ConcreteNetwork |

Prime engineers high-strength custom stamping and welding parts1 that form these elements. We apply certified materials and rapid prototyping2 from concept to delivery.

What Are Structural Elements in Literature? Examples?

In literature, structural elements1 define how stories are told—plot, setting, characters, conflict, and resolution.

These also guide business writing2 and manuals. We help engineers use this structure in proposals, guides, and reports.

| Literary Term | Engineering Equivalent | Example |

|---|---|---|

| Plot | Process flow | CNC: Design > Milling > Delivery |

| Character | Stakeholder roles | Buyer, Engineer, Operator |

| Setting | Use environment | Automotive, Aerospace, Marine |

| Conflict | Technical problem | Warping, misalignment, fatigue |

| Resolution | Tested solution | Tightened tolerance, upgraded material |

For clarity and conversion, we recommend structure-based writing as taught by Purdue OWL and Harvard.

What is Meant by Structural Elements?

Structural elements1 are functional parts that resist stress or support load.

They’re essential in engineering design2, whether visible or hidden within machinery or electronics.

| Industry | Structural Element | Prime Product Example |

|---|---|---|

| Automotive | Cross‑member beam | Laser-cut chassis supports |

| Machinery | Welded base frames | CNC or robotic welding structures |

| Construction | Load‑bearing brackets | Galvanized supports and braces |

| Electronics | Reinforced plastic housings | Molded casings with ribbing |

We provide ISO 9001-certified welding, CNC, and plastic injection services. Learn more on EngineeringToolbox and Autodesk.

What Are the Structural Elements of an Argumentative Text?

Argumentative text has five key structural elements: claim, evidence, counterargument1, rebuttal2, and conclusion.

We use these in quality reports, email replies, and certification proposals.

| Argument Part | Application | Prime Example |

|---|---|---|

| Claim | Your value offer | “Prime delivers fast, certified parts.” |

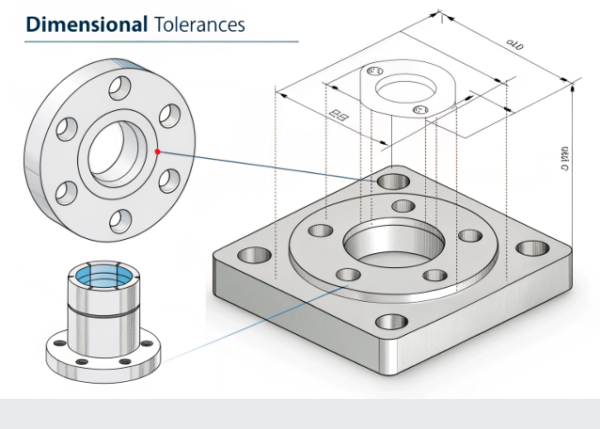

| Evidence | Data and reports | “ISO 9001, ±0.01mm tolerance record.” |

| Counterpoint | Buyer concern | “Delays from China shipping routes.” |

| Rebuttal | Assurance | “Partnered with DHL/FedEx; tracking available.” |

| Conclusion | CTA | “Start a free trial order today.” |

More on structure-based persuasion from UNC Writing Center and Grammarly Blog.

FAQs

1. What qualifies as a structural element?

Structural elements support or resist loads. These include beams, columns, brackets, or internal frames.

Learn more

2. Is Prime ISO certified?

Yes, we hold ISO 9001 certification for quality systems.

Certificate info

3. What file types do you accept for custom parts?

We support STEP, IGES, DXF, DWG, PDF, and native CAD files.

4. How fast can you ship?

15–30 days standard. We offer expedited service via DHL, FedEx, or UPS.

5. Can I order small batches?

Yes, MOQ starts at 5–50 pcs depending on product type. Alibaba MOQ Guide

6. How do you package delicate parts?

With foam, vacuum bags, pallets, and labels. Our packaging complies with export standards.

7. Do you support global customs and logistics?

Yes, we assist with documentation, customs clearance, and Incoterms.

Shipping terms guide

8. Do you provide inspection reports?

Yes. Full dimensional reports, material certs, and test records. Third-party inspection overview

9. Can I visit your factory?

Absolutely. We welcome factory audits and virtual inspections.

10. How can I request a quote?

Fill out our RFQ form on the website or email us directly at [email protected].

Conclusion & Call to Action

Structural elements—whether in machines, writing, or arguments—ensure strength, clarity, and trust.

At Shandong Prime International Trade Co., Ltd., we produce top-tier stamping parts1, CNC machined parts2, plastic housings, castings, and more.

We support:

- ISO-certified production

- Rapid prototyping

- Global delivery

- Custom drawings and dimensions

- Free professional consultation

📧 Contact us today: [email protected]

🌐 Website: https://primecustomparts.com

Let’s build your next precision part—strong, certified, and on time.