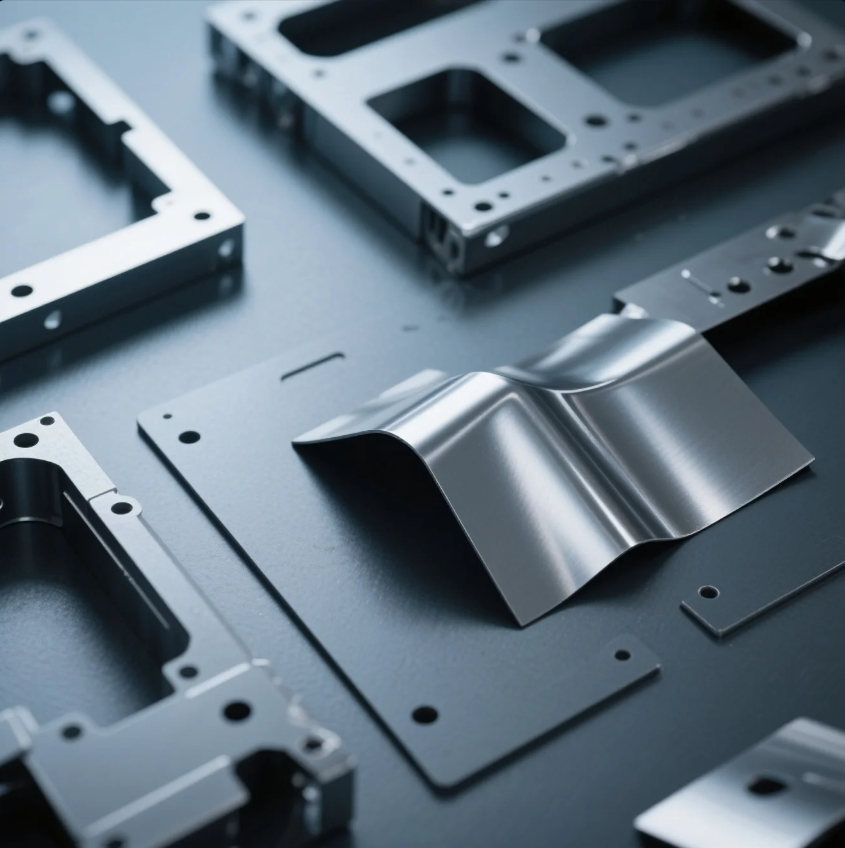

What are the advantages of using sheet metal parts?

Many buyers look for parts that balance strength, price, and performance.

Sheet metal parts are lightweight, strong, easy to shape, cost-effective, and recyclable, making them ideal for industrial applications.

If you understand their benefits and limits, you can avoid overpaying or underperforming parts. Let’s explore.

What are the advantages of sheet metals?

Some buyers still ask: why choose sheet metal over other materials?

Sheet metals are affordable, durable, corrosion-resistant, and easy to form into complex shapes.

They support high-volume production and precise customization. At Prime, we use stamping, welding, and CNC machining to create custom sheet metal parts. Clients from construction, telecom, and automotive sectors rely on us to deliver fast, strong, and clean-finished parts.

Key Benefits of Sheet Metal

| Advantage | Description |

|---|---|

| Lightweight | Easy to transport and install |

| Strong | High load-bearing capacity |

| Cost-effective | Great for bulk and repeat orders |

| Customizable | Can be cut, bent, welded, and coated |

| Corrosion-resistant | Long lifespan, especially with coatings |

We support multiple finishes including powder coating, galvanizing, and polishing to match customer needs.

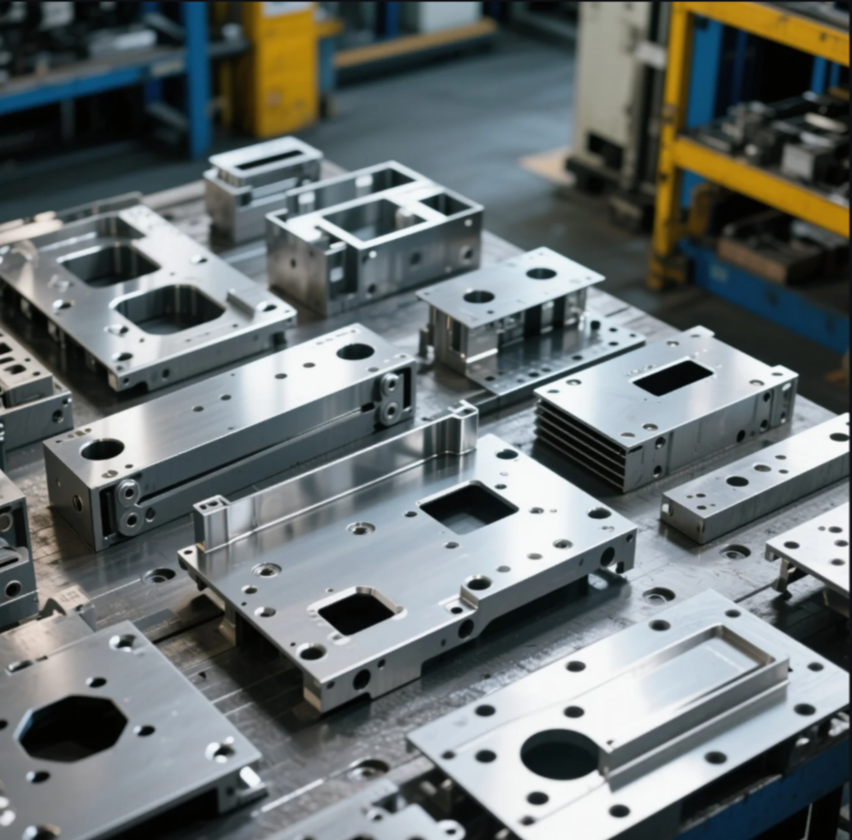

What are the advantages and disadvantages of sheet metal forming?

Forming is essential in making parts, but it’s not perfect.

Sheet metal forming is fast, repeatable, and great for complex shapes. However, it may require high tooling costs and has material limits.

Forming lets us create durable, detailed parts without removing material. At Prime, we use bending, drawing, punching, and stamping to meet precise specs. However, forming very thick or brittle materials can cause cracking or stress. That’s why we help clients choose the right sheet metal type before production begins.

Sheet Metal Forming Pros & Cons

| Pros | Cons |

|---|---|

| High-speed production | Tooling can be expensive |

| Low material waste | Limited to ductile materials |

| Excellent surface finish | Some designs may need post-processing |

| Precise shapes with tight tolerances | Not ideal for small one-off jobs |

We manage tooling in-house. That helps lower cost per unit on high-volume jobs and improves lead time.

What are the advantages of metal products?

Buyers want durable, long-lasting components. Metal offers exactly that.

Metal products are strong, stable, reusable, and suitable for extreme environments.

Metal outperforms plastic or wood when strength and fire resistance matter. At Prime, we produce metal enclosures, brackets, fasteners, and casting parts. Our CNC parts meet international tolerance standards. Our clients use them in automation, energy, and transportation industries where performance can’t be compromised.

Metal Product Strengths

- High tensile strength

- Heat resistance

- Electrical conductivity

- Long lifespan

- Easy to weld or bolt into assemblies

Our ISO-certified quality system ensures metal components work reliably in every application, from machinery to medical tools.

What are the advantages and disadvantages of metal?

No material is perfect. But metals offer more pros than cons.

Metals are durable, recyclable, and strong—but they can be heavy, costly, or prone to corrosion if untreated.

Choosing the right metal type matters. Stainless steel resists rust. Aluminum cuts weight. Mild steel lowers cost. At Prime, we help clients make the best material decision based on function, price, and environment.

General Pros and Cons of Metal

| Advantages | Disadvantages |

|---|---|

| Durable under pressure | Heavier than plastic |

| Easily formed or machined | Higher material cost |

| Good temperature tolerance | Can rust if untreated |

| Long service life | May conduct heat or electricity |

We apply coatings, plating, or painting to fix many metal weaknesses—without raising costs too much.

Conclusion

Sheet metal offers strength, flexibility, and reliability for industrial parts worldwide.

Need affordable and durable sheet metal parts? Contact Prime today for a free quote and technical consultation. We offer ISO-certified quality, fast delivery, and custom solutions across all industries.