What Are the Components of Casts?

Leading paragraph: When exploring the components of casts, understanding their makeup is crucial for both quality and functionality.

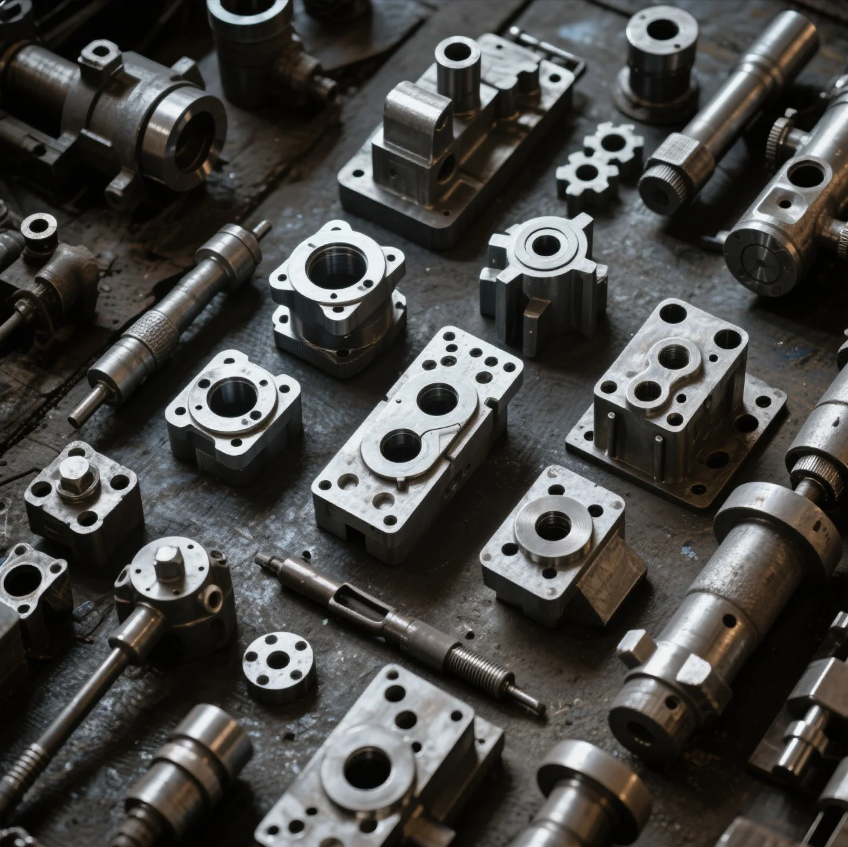

Snippet paragraph: Casts, commonly used in various industrial and medical applications, are composed of different elements. Each component plays a key role in ensuring strength and effectiveness. Understanding these parts can lead to better decisions when sourcing cast products.

Transition paragraph: Let’s dive deeper into the primary components that make up a cast. By grasping these elements, you can ensure the selection of high-quality cast parts for your needs.

What Is the Main Component of Casts?

Leading paragraph: The main component of any cast, whether used in industrial or medical settings, is the material from which it’s made. The base material determines the cast’s strength, flexibility, and durability.

Snippet paragraph: The base material in most casts is metal, such as aluminum or steel. These materials ensure the cast can handle stress and provide necessary support.

Dive-Deeper paragraph: Casts are typically made from either metal or synthetic compounds. The most common metal used is aluminum, as it’s lightweight, strong, and resistant to corrosion. For industrial applications, other metals like steel or iron might be used, depending on the specific needs for strength and temperature resistance.

Why Aluminum is the Most Common Metal for Casts

Aluminum is the primary metal used for casts in industries like automotive and machinery. It is favored for its low weight and high resistance to wear and corrosion. For applications where weight reduction is crucial, aluminum stands out.

| Property | Aluminum | Steel | Cast Iron |

|---|---|---|---|

| Weight | Light | Heavy | Heavy |

| Corrosion Resistance | High | Moderate | Low |

| Strength | Moderate | High | High |

What Does a Cast Consist Of?

Leading paragraph: Besides the base material, a cast includes several other elements that contribute to its structure and function. These additional components enhance its performance and application.

Snippet paragraph: A cast consists of several key parts: the base material, a binder, and sometimes reinforcement components. These elements vary based on the casting method.

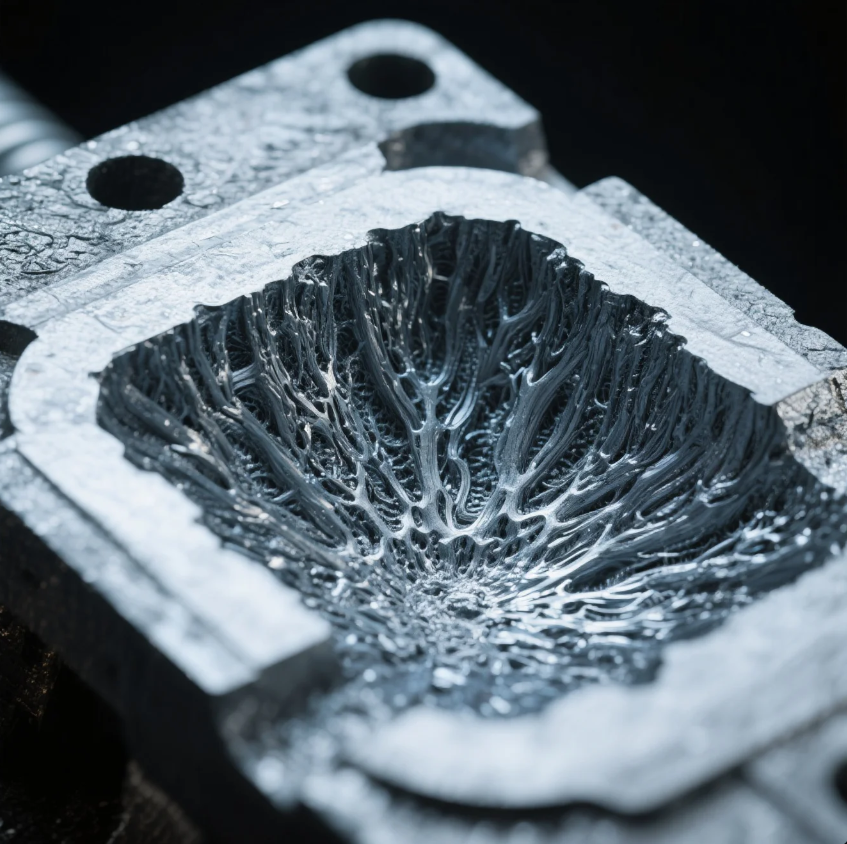

Dive-Deeper paragraph: In industrial casting processes, the base material (usually metal) is mixed with a binder to hold the shape of the mold. Some casts may also include reinforcement components like fibers or additional metals to improve the overall strength and stability of the product. For example, in sand casting, the sand itself acts as a binder to shape the molten metal, creating a durable cast.

Types of Reinforcement in Casts

Casts can sometimes be reinforced with fibers (glass or carbon fibers), or other metal alloys, especially in high-stress applications like aerospace or automotive industries. These reinforcements ensure the cast can handle extreme conditions without failure.

What Protein Are Casts Made Of?

Leading paragraph: While most industrial casts are made from metals, medical casts use different materials. One key component in medical casts is a protein-based compound called plaster of Paris.

Snippet paragraph: Plaster of Paris is the most common protein material used in medical casts. It hardens when mixed with water and provides the necessary support for fractures.

Dive-Deeper paragraph: Medical casts are usually made from plaster of Paris or fiberglass. Plaster of Paris contains calcium sulfate, which is mixed with water to form a moldable paste. This paste hardens quickly, making it ideal for immobilizing broken bones. Fiberglass casts, on the other hand, are lighter, more durable, and more water-resistant, but they are typically used for more long-term immobilization of fractures.

Plaster vs. Fiberglass Casts

While plaster is still widely used in emergency rooms, fiberglass casts have become more popular due to their lightweight nature and faster drying time. Plaster casts can be more uncomfortable for patients but are typically cheaper, whereas fiberglass casts offer better durability and ease of use.

What Does the Matrix of Casts Consist Of?

Leading paragraph: In both medical and industrial casts, the matrix refers to the structural elements that make up the cast. Understanding these elements can help ensure better material selection and application.

Snippet paragraph: The matrix of a cast is made up of the base material, binders, and reinforcement. It’s what gives the cast its overall structure and durability.

Dive-Deeper paragraph: The matrix is essentially the framework of the cast. In metal casting, this would be the material used to form the mold, often sand or other refractory materials. The molten metal fills this matrix to create the desired shape. In medical casts, the matrix is made up of the hardened plaster or fiberglass, which takes on the form of the mold or fracture.

The Importance of the Matrix in Industrial Casts

In industrial applications, the matrix plays a crucial role in ensuring the integrity of the cast. For high-performance parts, special matrices are used to ensure that the cast can withstand pressure, heat, and other extreme conditions.

Conclusion

In understanding the components of casts, it’s crucial to consider both the material and the matrix structure. Whether for industrial use or medical purposes, knowing the components can help you make better decisions in sourcing high-quality casts. If you are looking for reliable, customizable, and top-quality cast parts for your business, don’t hesitate to contact Prime today for a quote, consultation, and tailored solutions.

TEMPLATE_END