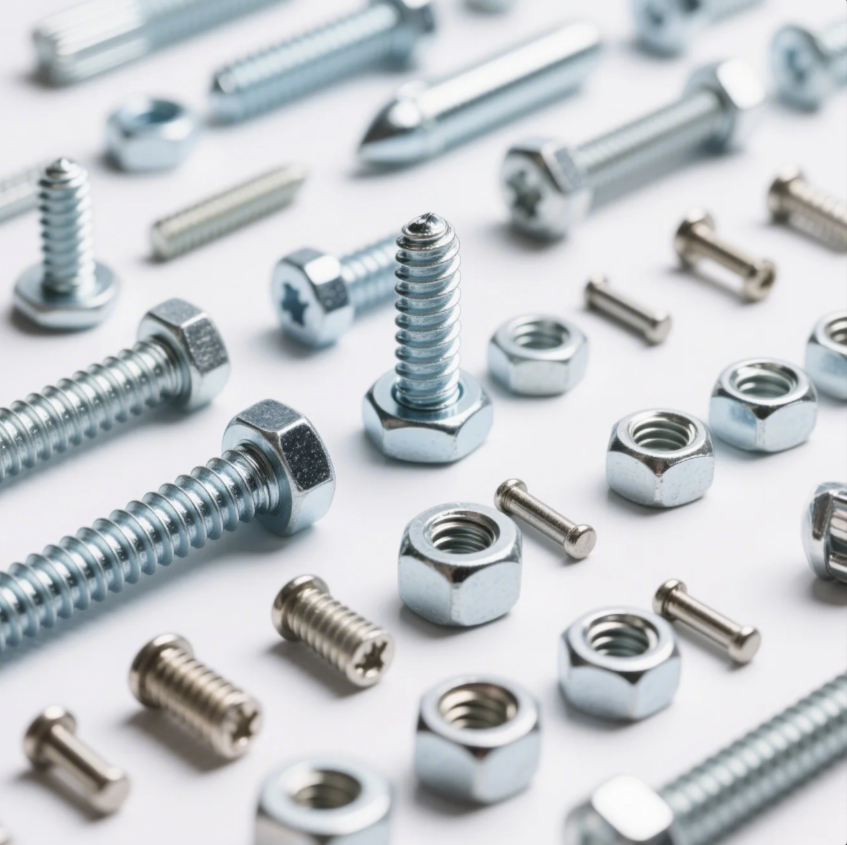

What are the different types of fastener clips?

Fastener clips are essential components used to hold materials together securely. With various types of clips available, understanding their functions and applications can help you choose the right one for your project.

Fastener clips come in different forms, each designed for specific uses. Below, we discuss various types of fasteners and metal clips.

To simplify the process of selecting fastener clips, let’s explore their types and how they can benefit your manufacturing or assembly processes. Continue reading for a detailed guide.

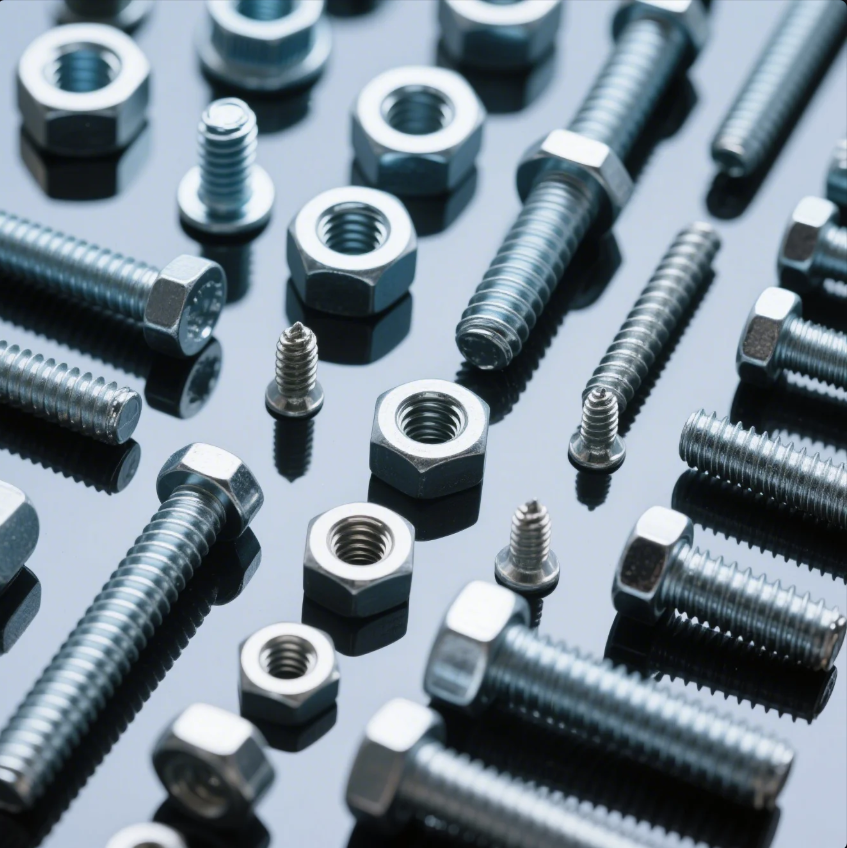

What are 7 types of fasteners?

Fasteners come in many shapes and forms, and understanding the types can help you choose the most suitable for your needs. Here’s an overview of 7 common fastener types:

Snippet paragraph: Fasteners include screws, nails, bolts, clips, rivets, nuts, and anchors. Each has unique applications and benefits in construction and manufacturing.

Dive-Deeper on Fasteners

Fasteners are crucial in various industries, especially in assembly lines, construction, and automotive manufacturing. Here’s a closer look at the 7 types of fasteners:

-

Screws: These are threaded fasteners that hold materials tightly together. Screws are highly versatile and come in various sizes and designs. Some are designed for specific tasks, like wood screws or machine screws.

-

Nails: Used primarily in wood construction, nails are simple fasteners that come in different shapes, lengths, and finishes. They are easy to drive in with a hammer but often require additional holding force or adhesives for better reliability.

-

Bolts: Bolts are heavy-duty fasteners used in construction, heavy machinery, and automotive applications. They provide strength and hold even under high stress.

-

Clips: Fastener clips come in a range of types and are often used to hold items in place temporarily or permanently. These include spring clips, retaining clips, and push-fit clips.

-

Rivets: Rivets are used for permanently joining materials. They are common in metalworking and construction, where a strong, permanent bond is needed.

-

Nuts: A nut is typically paired with a bolt. Nuts provide extra holding power when tightened onto a bolt, securing parts together.

-

Anchors: Used for fastening in hollow or concrete walls, anchors provide extra support for screws or bolts when additional strength is needed.

Each type of fastener plays a significant role depending on the application, material, and expected load. Choosing the right one can improve both safety and efficiency.

What are the 5 fasteners?

The five most common fasteners in many industries include screws, bolts, nuts, clips, and washers. Understanding their function will help you select the appropriate one for your needs.

Snippet paragraph: Fasteners like screws, bolts, nuts, clips, and washers are fundamental components in manufacturing. Each serves a unique role in fastening materials securely.

Dive-Deeper on Fastener Types

Let’s go a bit deeper into the roles of the five major fasteners:

-

Screws: These are the most commonly used fasteners and have a wide variety of applications. The threads on screws provide a secure fit, which makes them ideal for use in wood, metal, and plastic.

-

Bolts: Bolts are heavy-duty fasteners that provide superior strength when joining materials. They are often used in construction and machinery, where a strong, lasting bond is crucial.

-

Nuts: Nuts are paired with bolts to secure materials together. They are commonly used in automotive and machinery applications. When used with a bolt, they can withstand high pressure and prevent loosening.

-

Clips: Clips serve as a simple, quick, and often reusable fastening method. Spring clips or push-fit clips are often used to attach parts in assemblies or to secure items in place temporarily.

-

Washers: Washers provide an even surface to distribute pressure when a bolt or screw is tightened. They are useful for reducing friction and preventing damage to the material being fastened.

Each of these fasteners has its own application and is chosen based on the required strength, size, and type of material. When selecting fasteners, it is important to match the type to the specific task.

What are the different types of metal clips?

Metal clips come in various forms, each designed for specific uses in different industries. From automotive to construction, these clips are often used for securing parts, wires, or fasteners in place.

Snippet paragraph: Metal clips come in many variations, including spring clips, retaining clips, and snap clips. Each type is designed to meet specific fastening needs.

Dive-Deeper on Metal Clips

There are many types of metal clips, and selecting the right one depends on the application:

-

Spring Clips: These are flexible clips that use tension to hold items securely. Spring clips are commonly used in automotive and electronic devices for temporary attachment.

-

Retaining Clips: These clips are used to hold parts in place, preventing them from slipping off. They are widely used in mechanical and automotive applications.

-

Snap Clips: Snap clips, also known as push-on clips, are designed to easily snap into place, providing a firm hold. They are used in areas where quick and easy installation is important.

-

Clamping Clips: These clips apply pressure to clamp objects securely. They are commonly found in industrial and construction settings.

-

Wire Clips: Wire clips are designed specifically to hold wires or cables in place. They are often used in electrical and telecommunications industries.

By selecting the right metal clip, you can ensure that components stay securely in place, reducing the risk of failure or malfunction.

What are the different types of J clips?

J clips are one of the simplest yet highly effective fasteners used in a range of applications. These clips are typically used for securing wires, cables, and other components.

Snippet paragraph: J clips are essential for holding items like wires and components in place. They come in various forms, each designed for specific uses.

Dive-Deeper on J Clips

J clips are widely used for holding wires and cables in place, especially in automotive, electrical, and manufacturing industries. Here are some of the types of J clips:

-

Standard J Clips: These are used in a variety of basic applications, such as holding wires or securing light fixtures. They are simple to install and effective in light-duty applications.

-

Heavy-duty J Clips: These are designed for more industrial applications, where a stronger hold is needed. Heavy-duty J clips are commonly used for securing large wires or cables that experience high stress.

-

Insulated J Clips: These clips are designed to protect wires and cables from abrasion. The insulation ensures that wires do not get damaged when held tightly in place.

-

Adjustable J Clips: These clips can be adjusted to accommodate different sizes, making them more versatile. They are used in automotive and electrical applications, where different wire sizes may need to be secured.

-

Corrosion-resistant J Clips: These clips are designed for use in harsh environments. They are coated with materials that resist corrosion, making them ideal for marine or outdoor applications.

Choosing the right J clip depends on the specific needs of your application, including the size and type of material being held in place.

Conclusion

Fastener clips come in various types, including spring clips, retaining clips, and J clips, among others. Choosing the right fastener for your application ensures security, durability, and reliability.