What are the four types of metal stamping?

Metal stamping is not one-size-fits-all. Different jobs need different stamping methods.

The four main types of metal stamping are progressive die stamping, transfer die stamping, four-slide stamping, and deep draw stamping. Each serves different functions.

Choosing the wrong method can waste material and raise costs. In this article, I’ll explain each stamping type and how we at Prime help clients choose the best one for their mining or industrial parts.

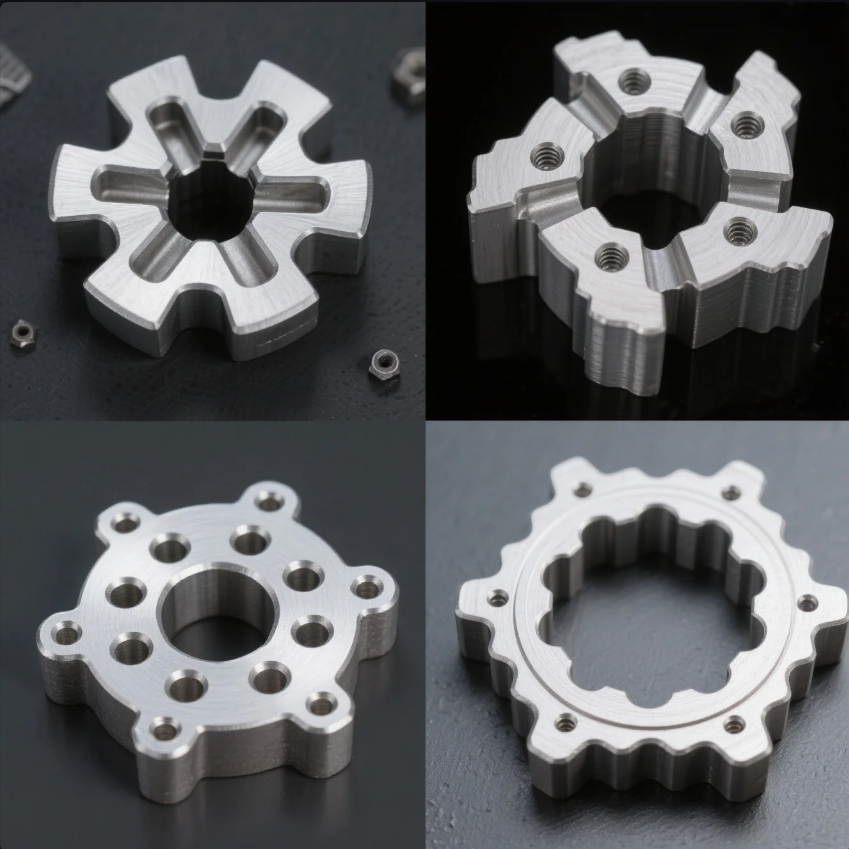

What are the different types of metal stamping?

Each stamping type has a specific purpose—some for speed, others for complex shapes or deep forms.

The four main types are progressive die, transfer die, four-slide, and deep draw stamping. Each method forms metal differently.

A closer look at stamping types

| Stamping Type | Best For | Common Applications |

|---|---|---|

| Progressive Die | High-speed, complex parts | Mounting brackets, electronic housings |

| Transfer Die | Large or heavy parts | Structural supports, mining plates |

| Four-Slide | Intricate bends, wire forms | Clips, electrical contacts |

| Deep Draw | Cylindrical or tall hollow shapes | Canisters, filter housings |

At Prime, we guide our clients through the selection process. For example, we may recommend progressive die stamping for high-volume 定制冲压件, or deep draw when producing sealed enclosures for mining sensors.

What are the different types of stamping machines?

Not all stamping machines work the same way. Some use mechanical force, others rely on hydraulics.

Stamping machines include mechanical presses, hydraulic presses, servo presses, and pneumatic presses.

Matching machines with stamping methods

Different machines offer different speed, force, and control levels. Here’s how we use them at Prime:

| Machine Type | Force System | Best For |

|---|---|---|

| Mechanical Press | Flywheel & crank | High-speed progressive die work |

| Hydraulic Press | Oil-based cylinder | Deep draw or thick part stamping |

| Servo Press | Programmable motor | Precision parts with speed control |

| Pneumatic Press | Compressed air | Light-duty or small-scale stamping |

Our factory operates 10 production lines with both hydraulic and mechanical presses. This allows us to provide both mass production and custom low-volume runs, depending on client needs.

Is metal stamping expensive?

The cost of stamping depends on tooling, material, and part complexity. For large volumes, it becomes highly cost-effective.

Stamping has high initial tooling costs but low per-part costs at scale. It’s affordable for long-term production.

Breaking down the stamping cost structure

| Cost Factor | Description |

|---|---|

| Tooling Cost | One-time cost for dies (\$500–\$5000+) |

| Material Cost | Depends on metal (steel, aluminum, etc.) |

| Labor & Setup | Spread across production runs |

| Per-Part Cost | Low once tooling is complete |

At Prime, we help buyers optimize costs by:

- Designing multi-use dies

- Using CNC零件精准加工 only where needed

- Suggesting better-fit stamping types based on order volume

Clients often ask us to re-engineer a machined part into a stamped one, which usually reduces costs by 30–50%.

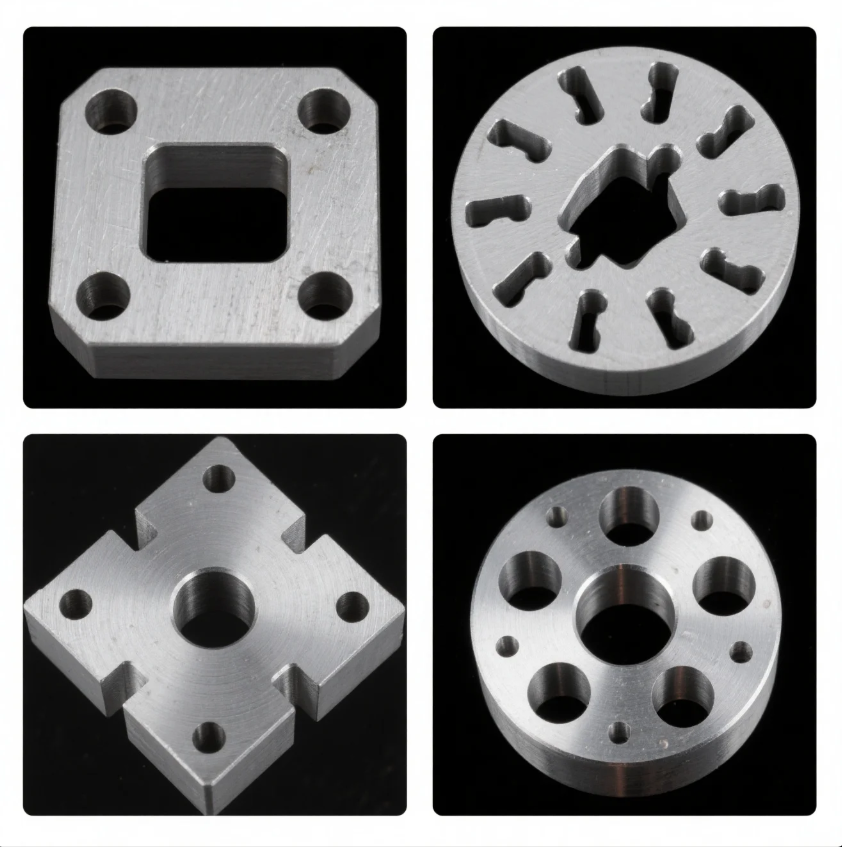

What equipment is used for stamping?

Stamping setups require presses, dies, feeding systems, and inspection tools to ensure quality output.

Stamping requires a press machine, tooling (die set), material feeding system, and quality control equipment.

Equipment used in a professional stamping setup

| Equipment Type | Purpose |

|---|---|

| Press Machine | Applies force to shape metal |

| Die Set | Defines the final part form |

| Coil Feeder | Feeds metal sheets or rolls |

| Ejector/Sorter | Removes and sorts finished parts |

| Inspection Tools | Measure dimensions and tolerances |

At Prime, we integrate real-time QC systems and automated feeding lines to improve efficiency and keep error rates below 1%. That’s how we maintain our ISO-certified quality and deliver to clients worldwide.

Conclusion

The four stamping types serve different needs. Choose the right one for stronger, faster, and cheaper production.

Need help choosing the right stamping method for your part? Contact Shandong Prime International Trade Co., Ltd. for custom die design, free production advice, and fast delivery of ISO-certified stamping parts. Our team is ready to optimize your parts for cost, quality, and performance.