What are the injuries of a blacksmith?

Many people are drawn to blacksmithing but worry about the risks involved.

This article explores the most common injuries blacksmiths face, how to prevent them, and how modern tools improve safety.

Knowing the risks helps you forge smarter and work longer.

What are the risks of being a blacksmith?

New buyers often ask if blacksmithing is a dangerous trade.

Blacksmiths face risks from heat, impact, sharp tools, and repetitive stress injuries.

Safety starts with awareness and preparation

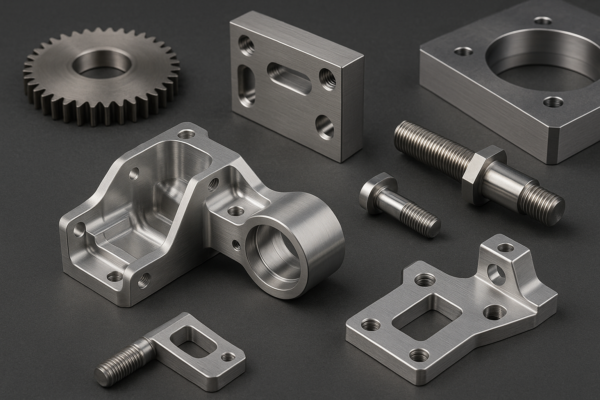

Blacksmithing involves high heat, heavy tools, and force. Injuries often result from poor protective gear, fatigue, or equipment failure. At Prime, we support safer workshops by supplying ergonomic tool parts, high-quality forging blanks, and custom safety-ready components.

| Risk Type | Example Injury | Prevention Tip |

|---|---|---|

| Burns | Contact with hot metal or forge | Use long tongs, gloves, eye protection |

| Impact injuries | Hammer blow to hand or leg | Focus, proper grip, balanced hammer |

| Eye damage | Flying slag or sparks | Always wear safety goggles |

| Back strain | Lifting anvils or long hours | Use proper stance + ergonomic tools |

| Hearing loss | Repeated hammer strikes | Use ear protection |

We help reduce these risks by producing custom-fitted forging tools, CNC-milled anvils, and precision hammer heads that improve control and safety.

What are the injuries in metalworking?

Blacksmiths aren’t the only ones facing workplace hazards.

Metalworking injuries often include burns, lacerations, repetitive strain, and long-term joint pain.

Metalworking safety overlaps with forging safety

From welding to grinding, metalworking creates physical strain and hazard exposure. That’s why workshops need PPE, organized layouts, and safe tools. Prime supports metalworkers with ready-to-use parts that reduce dangerous fabrication steps like raw cutting or heavy shaping.

| Injury Type | Source in Metalworking | Prime’s Prevention Contribution |

|---|---|---|

| Cuts/Lacerations | Sheet metal edges, grinding | Smooth-edged blanks, safer finishes |

| Eye injuries | Sparks, debris | Deburred parts, no burrs or slag |

| Lung exposure | Welding fumes, grinding dust | Clean materials, low-fume prep surfaces |

| Strain injuries | Repetitive work, lifting tools | Ergonomic tongs, balanced hammers |

Our clients appreciate that our ISO-certified forging process produces components that are not just functional—but safe to handle and easy to finish.

What is the average lifespan of a blacksmith?

Some clients ask if the physical toll shortens a blacksmith’s life.

Modern blacksmiths typically live into their 70s or 80s with proper safety and technique.

Technology and awareness are extending blacksmith careers

While older generations faced early health problems from fumes, fire, and fatigue, today’s smiths use cleaner fuels, better airflow, and lighter tools. Many of Prime’s clients are in their 50s and 60s, running profitable forges or training new artisans.

| Time Period | Common Lifespan of Blacksmith | Safety Conditions |

|---|---|---|

| 18th–19th Century | 50–60 years | Poor ventilation, no PPE |

| Mid-1900s | 60–70 years | Limited protection |

| Modern Era | 70–80+ years | PPE, ergonomic tools, clean fuel |

We manufacture lightweight forged hammers, safely packaged forging blanks, and custom vise assemblies—so today’s smiths work smarter, not harder.

How physically demanding is blacksmithing?

Customers often wonder if blacksmithing is only for the young and strong.

Blacksmithing is physically intense—but modern tools reduce the strain.

You don’t need to be a bodybuilder to be a blacksmith

Forging metal requires repeated movements, strong grips, and long hours. But it’s not about raw power—it’s about technique, consistency, and good equipment. Prime helps make blacksmithing more accessible by supplying ergonomically designed tools and pre-finished blanks that minimize heavy cutting or forging steps.

| Physical Challenge | Why It Matters | Prime’s Solution |

|---|---|---|

| Fatigue from hammering | Leads to loss of precision | Balanced forged hammer heads |

| Wrist/elbow strain | Caused by poor hammer grip | Weight-adjusted hammer sets |

| Overheating | Working near the forge too long | Quick-heating blanks, streamlined flow |

| Back strain | From poor posture or heavy tools | Lighter anvils, modular vises |

Our clients appreciate that our drop-forged and CNC-milled products not only boost efficiency—but help extend careers.

结论

Blacksmithing comes with risks—but with the right gear, materials, and habits, it’s a safe and rewarding trade.

At Prime, we don’t just make parts—we help protect your team. Our forged components, tool heads, and OEM kits are crafted to reduce injury, increase productivity, and support blacksmiths around the world.

👉 Contact us now for a free safety-friendly forging quote, or request custom parts designed to boost ergonomics and lower risk. With Prime, you forge with confidence.