What Are the Latest Innovations in Metal Stamping Technology?

I\’ve watched manufacturers struggle with outdated stamping technologies that limit design possibilities and drive up production costs, making it difficult to compete in today\’s demanding market.

The latest innovations in metal stamping technology include servo-driven presses, advanced simulation software, in-die sensing, and intelligent automation. These technologies improve precision by up to 30%, reduce setup time by 40-60%, and enable more complex part geometries while minimizing material waste.

Staying current with technological advancements can give your business a competitive edge in quality, efficiency, and capabilities. Let\’s explore the innovations transforming the stamping industry.

How are servo-driven presses changing the stamping industry?

I once managed a project using traditional mechanical presses that struggled with complex part geometries, leading to high scrap rates and quality inconsistencies that newer servo technology could have prevented.

Servo-driven presses are revolutionizing the stamping industry by providing programmable slide motion, adjustable stroke lengths, and precise control throughout the stamping cycle. This technology improves part quality by 25-30% while reducing material waste by up to 15% compared to conventional presses.

The transition from conventional to servo-driven presses represents one of the most significant technological shifts in the stamping industry. Through my experience implementing these systems, I\’ve seen firsthand how the enhanced control capabilities translate into tangible quality and efficiency improvements.

Comparing Servo Press Technology with Conventional Presses

Understanding the fundamental differences between servo and conventional press technology helps explain the performance advantages.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Motion Control | Fixed slide motion | Fully programmable motion profiles | Optimized forming for each part | |||||

| Speed Control | Limited adjustment | Precise control throughout stroke | Reduced material stress and defects | |||||

| Dwell Capability | Minimal to none | Extended dwell at any position | Improved part definition and accuracy | |||||

| Energy Efficiency | Lower efficiency, constant energy use | Higher efficiency, energy on demand | Reduced operating costs | |||||

| Noise Level | Higher noise | Significantly reduced noise | Improved working environment |

During my visit to Prime Custom Parts, I observed their servo press technology in action. The ability to program different motion profiles for different materials and part geometries allowed them to form complex parts that would have been impossible or required multiple operations on conventional equipment.

Advanced Applications of Servo Press Technology

The programmable nature of servo presses enables several advanced applications that create competitive advantages:

- Variable forming speeds: Slowing down during critical forming stages while maintaining high overall productivity

- Pendulum motion: Oscillating the slide during forming to improve material flow

- Dwell periods: Holding pressure at bottom dead center to improve part definition

- Soft-touch capabilities: Approaching the material slowly to improve positioning accuracy

- Energy optimization: Adjusting power consumption based on actual forming requirements

For a challenging aerospace component with tight tolerances, I worked with a manufacturer using servo press technology to develop a custom motion profile. By slowing the press during critical forming stages and implementing a dwell period at bottom dead center, they achieved a 40% reduction in dimensional variation while actually increasing overall production speed by 15%.

How is simulation software improving stamping part design and production?

I once approved a stamping tool design without simulation verification, resulting in unexpected material thinning during production that caused part failures and required costly tool modifications.

Advanced simulation software is transforming stamping by predicting material behavior before tool production. These programs accurately model forming forces, material flow, and potential defects, reducing tool development time by 30-50% while virtually eliminating design-related production issues.

The evolution of simulation capabilities has fundamentally changed the stamping development process. My experience implementing simulation-driven design approaches has demonstrated that the upfront investment in simulation pays tremendous dividends through reduced development cycles and eliminated production problems.

Key Capabilities of Modern Stamping Simulation Software

Today\’s simulation tools offer sophisticated capabilities that address multiple aspects of the stamping process.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Formability Analysis | Material thinning, wrinkling, splitting | Prevents design-related defects | Moderate | |||||

| Springback Prediction | Dimensional changes after forming | Enables compensation in tool design | High | |||||

| Material Flow Modeling | How material moves during forming | Optimizes blank size and shape | Moderate | |||||

| Process Optimization | Best process parameters | Reduces trial and error | High | |||||

| Virtual Die Tryout | Complete forming process | Minimizes physical tryout iterations | Very High |

When consulting with an automotive supplier, we implemented a simulation-driven development process for a complex structural component. The simulation identified potential thinning issues that would have caused field failures if undetected. By modifying the part design before any tooling was cut, they avoided an estimated $175,000 in tool modifications and prevented a three-month program delay.

Integrating Simulation into the Development Process

The most effective implementation of simulation technology follows these key principles:

- Early involvement: Apply simulation during initial design phases, not just verification

- Iterative approach: Use simulation results to guide design improvements

- Material characterization: Invest in accurate material data for simulation inputs

- Validation protocols: Correlate simulation results with physical testing

- Knowledge management: Capture insights from simulations for future projects

During my collaboration with Prime Custom Parts, I was impressed by their integrated design approach that incorporates simulation from the earliest concept stages. Their engineers use simulation tools to explore multiple design alternatives before committing to a final approach, resulting in a first-time success rate exceeding 90% for new tool designs.

What advancements in in-die sensing are improving stamping quality?

I once managed a stamping operation that produced thousands of defective parts before a quality issue was detected during final inspection, a problem that modern in-die sensing would have caught immediately.

Advanced in-die sensing technology is revolutionizing stamping quality control through real-time monitoring of forming forces, material positioning, and tool conditions. These systems detect anomalies within milliseconds, enabling immediate correction and reducing defect rates by 70-90% compared to traditional inspection methods.

In-die sensing represents a paradigm shift from detecting defects to preventing them. My experience implementing these systems has shown that the ability to monitor the actual forming process in real-time provides quality assurance that simply cannot be matched by even the most rigorous post-process inspection.

Types of Sensors Transforming Stamping Operations

Various sensor technologies address different aspects of the stamping process.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Force Sensors | Forming and cutting forces | Material variations, tool wear | Moderate | |||||

| Vision Systems | Part positioning, presence | Missing features, misalignment | High | |||||

| Acoustic Sensors | Sound patterns during operation | Tool breakage, abnormal conditions | Moderate | |||||

| Proximity Sensors | Material presence and position | Double feeds, misfeeds | Low | |||||

| Dimensional Sensors | Critical part dimensions | Out-of-tolerance conditions | High |

When working with a medical device component manufacturer, we implemented a comprehensive in-die sensing system for a critical stamping operation. The force monitoring sensors detected subtle variations in material thickness that affected part performance but were undetectable through visual inspection. This system prevented an estimated 12,000 defective parts annually that would have otherwise reached assembly operations or customers.

Creating Integrated Monitoring Systems

The full potential of in-die sensing is realized through integrated monitoring approaches:

- Multi-sensor integration: Combining different sensor types for comprehensive monitoring

- Real-time analysis: Processing sensor data to identify patterns and anomalies

- Automated responses: Implementing immediate corrective actions when issues are detected

- Data collection: Capturing process data for trend analysis and improvement

- Predictive capabilities: Using patterns to anticipate potential issues before they occur

What Are the Latest Innovations in Metal Stamping Technology? During my visit to Prime Custom Parts, I observed their sophisticated monitoring system that integrates multiple sensor types with automated press controls. When anomalies are detected, the system can automatically adjust process parameters or stop the operation before defective parts are produced. This approach has enabled them to achieve near-zero defect rates for their most critical components.

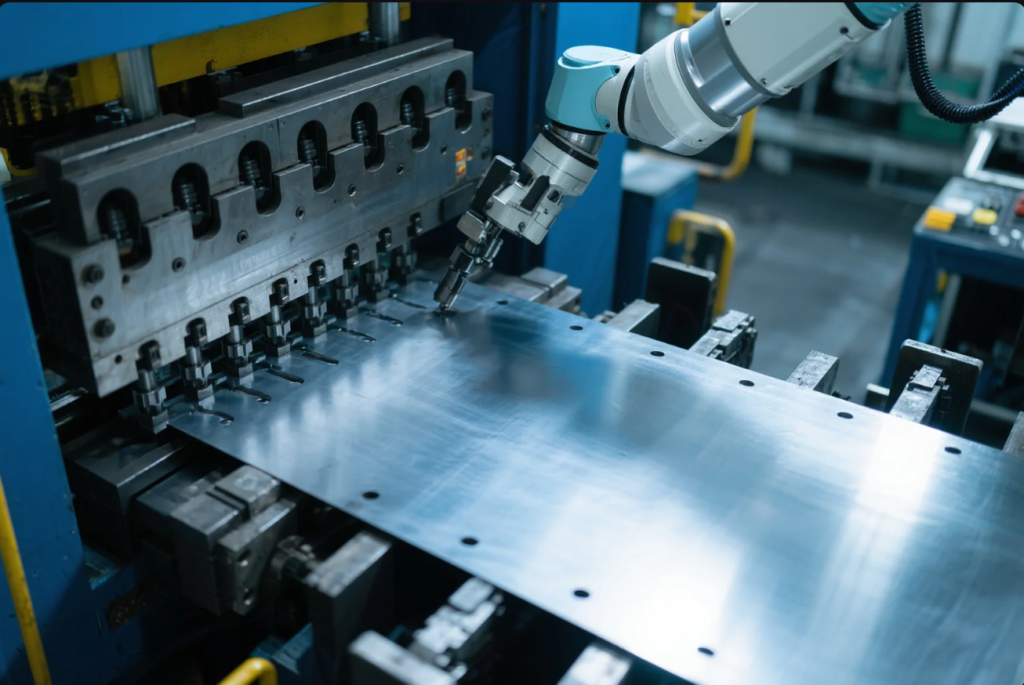

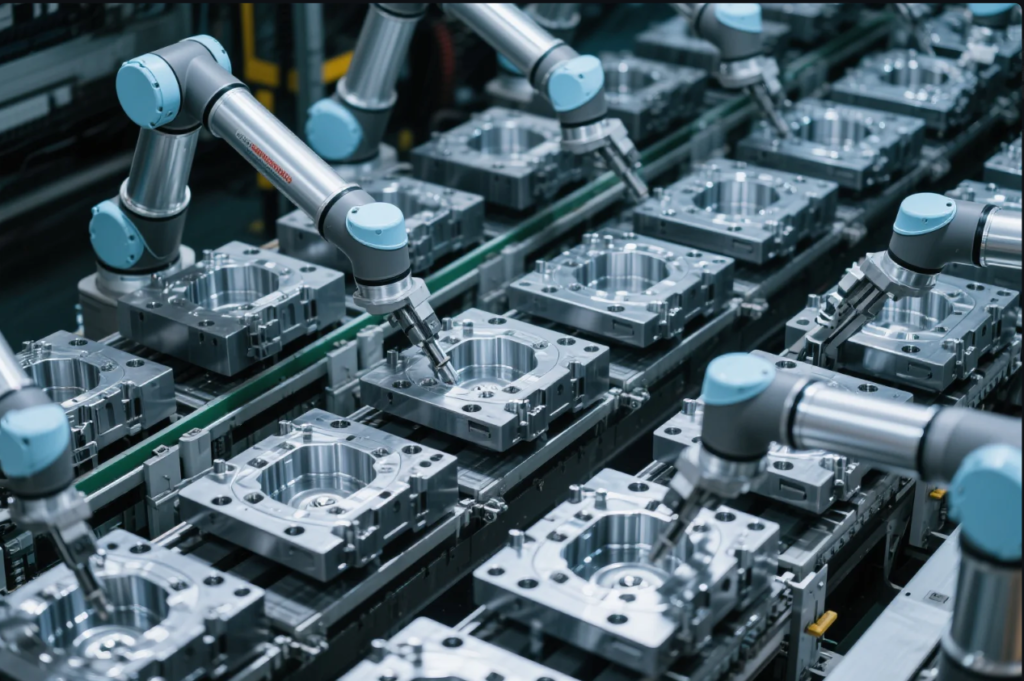

How is automation transforming the stamping industry?

I previously managed a labor-intensive stamping operation with inconsistent quality and frequent injuries until implementing automation that dramatically improved safety, quality, and productivity.

Advanced automation is transforming stamping operations through robotic material handling, automated tool changes, and integrated quality verification. These systems increase productivity by 30-50%, improve consistency by eliminating human variability, and enhance safety by removing operators from hazardous tasks.

The evolution of automation in stamping has progressed far beyond simple pick-and-place robots. My experience implementing these systems has shown that modern automation creates a fundamental shift in both capabilities and economics, enabling levels of efficiency and quality that were previously unattainable.

Key Automation Technologies in Modern Stamping

Several automation technologies are particularly impactful in stamping operations.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Robotic Material Handling | Loading/unloading, part transfer | Consistency, reduced labor | Requires standardized processes | |||||

| Automated Tool Changes | Quick changeover between jobs | Reduced setup time, flexibility | Higher initial investment | |||||

| Vision-Guided Systems | Part location, orientation | Accommodates variation, quality verification | Programming complexity | |||||

| Coil Handling Systems | Material feeding, straightening | Consistent material presentation | Space requirements | |||||

| Integrated Inspection | Automated quality verification | 100% inspection capability | Sensor selection and calibration |

When consulting with an electronics component manufacturer, we implemented a fully automated stamping cell that integrated robotic material handling with in-line inspection. This system reduced labor requirements by 70% while improving first-pass quality rates from 98.2% to 99.8%, creating both cost savings and quality improvements.

The Evolution Toward Smart Manufacturing

Modern stamping automation is increasingly incorporating smart manufacturing principles:

- Connected systems: Integration between equipment and business systems

- Data analytics: Using production data to drive continuous improvement

- Predictive maintenance: Anticipating equipment needs before failures occur

- Flexible automation: Quickly adapting to different product requirements

- Remote monitoring: Overseeing operations from anywhere in real-time

What Are the Latest Innovations in Metal Stamping Technology? During my collaboration with Prime Custom Parts, I was impressed by their implementation of smart manufacturing principles. Their stamping operations feature connected systems that provide real-time production data, predictive maintenance alerts, and remote monitoring capabilities. This approach has enabled them to achieve overall equipment effectiveness (OEE) rates exceeding 85%, well above industry averages.

What innovations in material feeding systems are improving stamping efficiency?

I once managed a stamping operation plagued by material feeding issues that caused frequent stoppages and quality problems until implementing advanced feeding technology that transformed reliability.

Innovative material feeding systems including servo-driven feeds, precision straighteners, and loop control systems are dramatically improving stamping efficiency. These technologies increase feeding accuracy by up to 50%, reduce setup time by 30-40%, and minimize material waste through optimized feed length control.

Material feeding represents a critical but often overlooked aspect of stamping efficiency. My experience optimizing stamping operations has shown that even the most advanced press technology cannot overcome limitations in material feeding systems, making these innovations particularly valuable for overall productivity.

Comparing Advanced Feeding Technologies

Several feeding technologies offer different advantages for various applications.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Servo-Driven Feeds | Precise positioning, programmable profiles | High-precision parts, variable progression | Higher initial cost | |||||

| Electronic Roll Feeds | Consistent feeding, moderate precision | Medium to high volume production | Less precise than servo feeds | |||||

| CNC Straighteners | Automated adjustment, material flatness | Critical flatness requirements | Setup complexity | |||||

| Multi-Axis Feeds | Complex feed patterns, non-linear movement | Specialized forming operations | Programming complexity | |||||

| Compact Feeds | Space-efficient design, integration with die | Limited space applications | Reduced functionality |

What Are the Latest Innovations in Metal Stamping Technology? When working with an automotive supplier, we upgraded their feeding systems from conventional mechanical feeds to servo-driven technology. This change improved feed accuracy from ±0.2mm to ±0.05mm, which eliminated material misalignment issues that had been causing approximately 3% scrap rate. The improved accuracy also enabled tighter progression in the tool design, reducing material usage by 7%.

Integrating Feeding Systems with Press Technology

The most effective feeding implementations create seamless integration with press systems:

- Synchronized operation: Coordinating feed timing with press motion

- Programmable parameters: Adjusting feed characteristics for different materials

- Quick-change capabilities: Reducing setup time between jobs

- Feedback systems: Monitoring actual material movement

- Preventive diagnostics: Identifying potential issues before they cause problems

During my visit to Prime Custom Parts, I observed their integrated approach to material handling that coordinates servo-driven feeds with their press systems. This synchronization allows for optimized material movement during the press cycle, increasing both speed and accuracy while reducing wear on tooling and feeding components.

How are advances in tooling materials improving stamping performance?

I once managed a high-volume stamping operation where traditional tool steel wore rapidly, causing frequent maintenance interruptions until implementing advanced tooling materials that extended run times by 300%.

Advanced tooling materials including powder metallurgy steels, ceramic inserts, and PVD coatings are significantly improving stamping performance. These materials extend tool life by 200-500%, maintain dimensional precision longer, and enable processing of harder materials that would quickly damage conventional tools.

Tooling materials represent a critical factor in stamping economics and capabilities. My experience optimizing high-volume operations has shown that investments in premium tooling materials typically deliver exceptional returns through extended tool life, reduced maintenance, and improved part quality.

Comparing Modern Tooling Materials

Various advanced materials offer different performance characteristics for stamping applications.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Powder Metallurgy Steel | Wear resistance, toughness | High-volume production, abrasive materials | $$$ | |||||

| Carbide Inserts | Extreme hardness, wear resistance | Cutting operations, abrasive materials | $$$$ | |||||

| PVD Coatings | Surface hardness, reduced friction | Forming operations, material adhesion issues | $$ (as addition) | |||||

| Ceramic Components | Heat resistance, chemical stability | High-temperature applications | $$$$$ | |||||

| Cryogenically Treated Steel | Improved wear resistance, dimensional stability | Precision applications | $$ (as treatment) |

What Are the Latest Innovations in Metal Stamping Technology? When consulting with a consumer electronics manufacturer, we implemented powder metallurgy tool steel for a high-volume stamping operation processing silicon steel. This change extended average tool life from 250,000 hits to over 1 million hits before maintenance was required, dramatically improving productivity and reducing per-part tooling costs by 68%.

Strategic Implementation of Advanced Tooling Materials

The most cost-effective approach to tooling materials follows these principles:

- Selective application: Using premium materials only where they provide clear benefits

- Modular design: Creating replaceable inserts for high-wear areas

- Material matching: Selecting specific materials based on application requirements

- Surface treatments: Enhancing conventional materials with advanced coatings

- Maintenance optimization: Developing protocols specific to advanced materials

During my collaboration with Prime Custom Parts, I was impressed by their strategic approach to tooling materials. Rather than applying premium materials throughout entire tools, they use sophisticated wear analysis to identify critical areas that benefit most from advanced materials. This targeted approach optimizes the cost-benefit ratio while achieving exceptional tool performance.

What digital technologies are transforming stamping operations?

I previously managed a stamping department that relied on paper documentation and manual data collection until implementing digital systems that dramatically improved visibility, decision-making, and continuous improvement capabilities.

Digital technologies including IoT sensors, cloud-based monitoring, digital twins, and AI-powered analytics are transforming stamping operations. These systems provide real-time performance data, predict maintenance needs, optimize process parameters, and enable remote monitoring and management.

What Are the Latest Innovations in Metal Stamping Technology? The digitalization of stamping operations represents a fundamental shift from experience-based to data-driven decision making. My experience implementing these technologies has shown that the visibility and insights they provide enable levels of optimization and improvement that simply weren\’t possible with traditional approaches.

Key Digital Technologies Impacting Stamping

Several digital technologies are particularly valuable for stamping operations.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| IoT Sensors | Real-time data collection | Comprehensive monitoring, early detection | Moderate | |||||

| Cloud-Based Systems | Data storage, remote access | Anywhere access, scalable storage | Moderate | |||||

| Digital Twins | Virtual process modeling | Scenario testing, optimization | High | |||||

| AI Analytics | Pattern recognition, prediction | Anomaly detection, process optimization | High | |||||

| Augmented Reality | Visualization, guided maintenance | Reduced training time, improved accuracy | Moderate |

When working with a major automotive supplier, we implemented a comprehensive IoT system that collected data from their stamping presses, feeding systems, and in-die sensors. Within three months, the pattern recognition algorithms identified subtle correlations between ambient temperature fluctuations and dimensional variations in critical components. Addressing this previously unknown factor improved first-time quality rates from 98.3% to 99.7%.

Creating Integrated Digital Ecosystems

The full potential of digital technologies is realized through integrated implementation:

- Connected systems: Ensuring data flows between different technologies

- Standardized platforms: Creating common interfaces and data structures

- Scalable architecture: Building systems that can grow with changing needs

- Security protocols: Protecting sensitive production and design data

- User-focused interfaces: Making data accessible and actionable

What Are the Latest Innovations in Metal Stamping Technology? During my visit to Prime Custom Parts, I observed their integrated digital ecosystem that connects design systems, production equipment, quality verification, and business management. This comprehensive approach provides unprecedented visibility into their operations, enabling data-driven decisions at every level from the press operator to executive management.

How are sustainable technologies changing the stamping industry?

I once managed a stamping operation with significant environmental impact until implementing sustainable technologies that reduced energy consumption by 40% and material waste by 35% while improving overall productivity.

Sustainable technologies including energy-efficient equipment, advanced lubrication systems, and material optimization software are transforming the stamping industry. These innovations reduce energy consumption by 30-50%, minimize hazardous waste, and decrease material usage while maintaining or improving part quality.

Sustainability in stamping has evolved from a regulatory compliance issue to a competitive advantage. My experience implementing sustainable practices has consistently shown that environmental improvements typically deliver significant economic benefits through reduced costs, improved efficiency, and enhanced market positioning.

Key Sustainable Technologies in Stamping

Several technologies are particularly effective in improving stamping sustainability.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Energy-Efficient Presses | Reduced power consumption, lower operating costs | Higher initial investment | Medium (2-4 years) | |||||

| Minimal Lubrication Systems | Reduced chemical usage, cleaner parts | Process adjustment, testing | Short (1-2 years) | |||||

| Material Optimization Software | Reduced material waste, lower costs | Training, design process changes | Short (6-18 months) | |||||

| Closed-Loop Cooling | Water conservation, consistent temperature | Installation complexity, space | Medium (2-3 years) | |||||

| Scrap Reduction Systems | Improved material utilization, reduced waste | Process engineering, tooling modifications | Short to Medium |

What Are the Latest Innovations in Metal Stamping Technology? When consulting with a consumer products manufacturer, we implemented a comprehensive sustainability program for their stamping operations. The energy-efficient equipment and minimal lubrication systems reduced operating costs by 28%, while the material optimization software decreased material usage by 12%. These improvements delivered a complete return on investment in just 22 months while significantly reducing environmental impact.

Integrating Sustainability into Business Strategy

The most effective sustainability approaches align environmental and business objectives:

- Economic alignment: Focusing on initiatives that deliver both environmental and financial benefits

- Performance metrics: Establishing clear sustainability KPIs alongside traditional measures

- Customer engagement: Communicating sustainability achievements to environmentally conscious customers

- Continuous improvement: Treating sustainability like quality—always seeking enhancement

- Cultural integration: Making sustainability part of the organizational mindset

During my collaboration with Prime Custom Parts, I was impressed by their integrated approach to sustainability. Their ISO 14001 certification demonstrates their commitment to environmental management systems, while their material optimization and energy efficiency initiatives have created measurable improvements in both environmental impact and operational costs.

Contact Us

📧 Email us: [email protected]🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.

Conclusion

The latest innovations in metal stamping technology are transforming what\’s possible in terms of part complexity, production efficiency, and quality consistency. By embracing servo-driven presses, advanced simulation software, in-die sensing, intelligent automation, advanced feeding systems, premium tooling materials, digital technologies, and sustainable practices, manufacturers can achieve unprecedented levels of performance and competitiveness in today\’s demanding market.