What Are the Most Common Surface Treatments for Metal Parts in 2025?

Surface flaws lead to rust, wear, and failure.

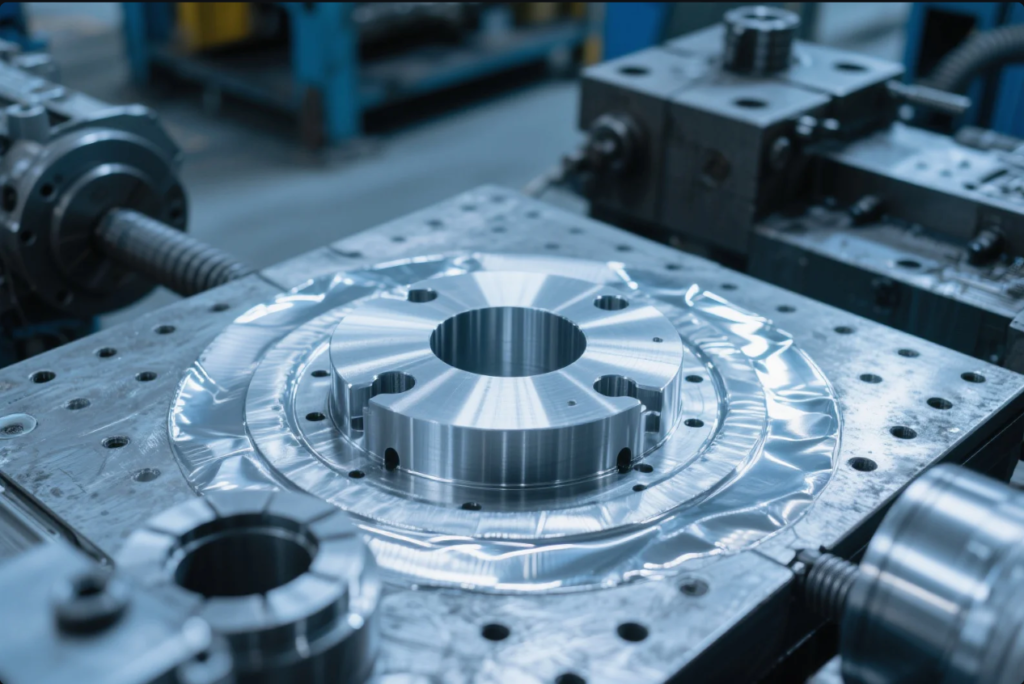

Metal surface treatments enhance strength, resist corrosion, and improve appearance. Discover the top options in 2025.

The wrong finish can ruin a great part. Keep reading to find out how to choose the right surface treatment for your metal components in 2025.

What are the surface treatments for metal?

Rust and fatigue weaken metal over time. Buyers need durable finishes that withstand harsh use and time.

Common treatments include powder coating, galvanizing, anodizing, plating, polishing, and black oxide. Each has unique benefits.

Many clients ask us: which surface treatment should I use? The answer depends on function, environment, and material. We’ve tested hundreds of combinations to help global clients find the right finish. Let me walk you through the most trusted options we use here at Prime.

📌 Most Used Metal Surface Treatments Today

| Treatment Type | Key Benefit | Typical Use Cases |

|---|---|---|

| Powder Coating | Durability + aesthetics | Consumer goods, tools |

| Galvanizing | Corrosion resistance | Outdoor steel parts, fasteners |

| Anodizing (Alu.) | Scratch resistance | Aerospace, electronics |

| Electroplating | Decorative + wear proof | Auto parts, decorative hardware |

| Black Oxide | Anti-rust + appearance | Tools, mechanical components |

| Sandblasting | Clean + prep surface | Pre-treatment for coatings |

We offer all these finishes at Prime, including custom textures and thickness control.

What manufacturing processes are used to modify metal surface material properties?

Corrosion, abrasion, and fatigue wear down untreated parts. Precision buyers want enhanced durability and extended part life.

Key processes include heat treatment, shot peening, carburizing, nitriding, and surface hardening. These enhance strength, wear, and fatigue resistance.

Over the years, we’ve seen more clients demand enhanced wear resistance—especially in CNC machined parts. At Prime, we apply surface engineering techniques based on industry-specific needs.

🔧 Deep Dive into Surface Engineering Methods

Heat Treatment vs Surface Hardening

| Method | Purpose | Applications |

|---|---|---|

| Carburizing | Harden surface layer | Gears, shafts |

| Nitriding | Wear + fatigue strength | Tools, engine parts |

| Induction Hardening | Tough core, hard surface | Automotive components |

We also offer shot peening, a mechanical process that increases fatigue resistance by applying compressive stress to the surface. This technique is popular for welded parts and casting reinforcements.

Clients often combine these with coating solutions, such as zinc plating over hardened parts, for complete protection. That’s one reason clients trust Prime—we understand how different treatments work together.

What is the last treatment applied to the surface of a work piece?

Final finishing defines the part’s durability, aesthetics, and customer experience. A poor finish can ruin product trust.

The last treatment is typically a protective coating—paint, plating, or oiling—based on application needs and logistics.

At Prime, we always consult with clients to determine what final coating suits their part’s environment and customer expectations. For example, fasteners shipped to coastal regions need heavy-duty anti-rust coatings, while CNC parts for medical devices need cleanroom-compatible anodizing.

✨ Packaging and Post-Treatment Matter

Last-Step Treatments Include:

- Anti-rust oiling (for storage + shipping)

- Final polishing (for visual parts)

- Powder coating or painting (for long-term wear and appearance)

- Dry-film lubrication (for moving metal parts)

We also implement strict quality checks after surface treatment. Then, we apply custom protective packaging, like VCI bags or anti-scratch wraps, especially for sensitive finishes. That’s why Prime’s reputation in ISO-certified casting parts manufacturer stands strong worldwide.

What is laser surface treatment of metals?

Traditional coatings wear off or peel under stress. High-end clients want lasting strength without adding bulk.

Laser surface treatment uses focused laser beams to modify metal surfaces. It increases hardness, corrosion resistance, and fatigue life.

We’ve been exploring laser surface texturing for specialized parts—especially for clients in aerospace, auto, and defense. The process works by melting a thin surface layer to restructure the metal without affecting the core.

🔬 How Laser Surface Treatment Works

Process Breakdown:

- A laser scans the metal surface

- Heat alters the microstructure

- Properties improve without adding material

| Laser Type | Use Case |

|---|---|

| Nd\:YAG Laser | Surface hardening on steels |

| Fiber Laser | Precision marking, surface texturing |

| CO₂ Laser | Cleaning + pre-treatment |

Laser treatments are especially useful when weight and space constraints limit the use of coatings or plating. Prime is among the few custom stamping parts suppliers in China actively testing this technology for repeatable industrial results.

FAQs

Q1: What is the most cost-effective surface treatment for corrosion resistance?

A1: Galvanizing is often the most cost-effective method for corrosion resistance, especially for steel parts exposed to outdoor environments.

Q2: Can laser surface treatment be applied to all metals?

A2: Laser surface treatment is versatile and can be applied to various metals, including steel, aluminum, and titanium. However, the specific laser parameters must be tailored to each material.

Q3: How does anodizing differ from electroplating?

A3: Anodizing is an electrolytic process that increases the natural oxide layer on the surface of metals like aluminum, enhancing corrosion resistance and allowing for dyeing. Electroplating involves depositing a metal layer onto the surface of a part for improved appearance and corrosion resistance.

Q4: What surface treatment is recommended for parts requiring high wear resistance?

A4: For high wear resistance, treatments like induction hardening, carburizing, or applying hard chrome plating are recommended, depending on the base material and application.

Q5: How do I choose the right surface treatment for my application?

A5: Selecting the appropriate surface treatment depends on factors like the base material, environmental conditions, desired appearance, and functional requirements. Consulting with experts, like our team at Prime, can help determine the best solution.

Conclusion

Surface treatment is key to quality, life, and trust.

Looking for expert guidance on surface finishing for your metal parts? Contact Prime today for free consulting, accurate quotes, and tailored solutions. We deliver fast, consistent, and certified results trusted worldwide.

Visit our website: https://primecustomparts.com/

Email us at: [email protected]