What are the most common types of sheet metal?

Choosing the right type of sheet metal often confuses buyers.

The most common types of sheet metal are steel, aluminum, copper, and stainless steel. Each has unique properties and pricing.

If you pick the wrong type, it may raise your costs or cause part failure. Let’s explore the right materials for your project.

Is a sheet metal worker the same as a fabricator?

Many buyers think these roles are identical. But they’re not.

A sheet metal worker shapes metal sheets. A fabricator builds full parts or assemblies from different materials.

The difference lies in scope. Sheet metal workers mainly cut, bend, and form thin sheets. Fabricators handle welding, assembly, and full system builds. At Prime, our team includes both. We handle precision sheet metal stamping and full fabrication, from design to packaging. That’s why many B2B clients trust us with bulk projects that need both services.

Sheet Metal Worker vs Fabricator

| Role | Key Responsibilities | Tools Used |

|---|---|---|

| Sheet Metal Worker | Bending, cutting, forming sheets | Press brakes, shears |

| Fabricator | Assembly, welding, machining | MIG/TIG welders, grinders |

| Project Focus | Individual components | Finished assemblies |

Clients benefit more when one supplier handles both. It reduces risk and ensures smoother communication.

What is the cheapest type of sheet metal?

Cost matters. Many buyers want low-cost but strong sheet metal options.

Mild steel is the cheapest sheet metal. It offers good strength and is easy to form and weld.

Mild steel works well for many parts like brackets, enclosures, and supports. It’s widely available and easy to process. That helps reduce production time and total costs. At Prime, we often recommend cold rolled steel for cost-sensitive projects. It performs well for medium-strength needs. When clients want corrosion resistance, we offer galvanized versions at slightly higher prices.

Sheet Metal Cost Comparison (Per Kg – Estimated)

| Material | Approximate Cost | Strength | Rust Resistance |

|---|---|---|---|

| Mild Steel | \$0.50–\$0.80 | Medium | Low |

| Aluminum | \$1.50–\$2.50 | Medium | High |

| Stainless Steel | \$2.00–\$3.00 | High | Very High |

| Copper | \$6.00+ | Medium | High |

We help clients choose the best option based on their budget and performance goals. Our ISO-certified processes ensure quality, no matter the material.

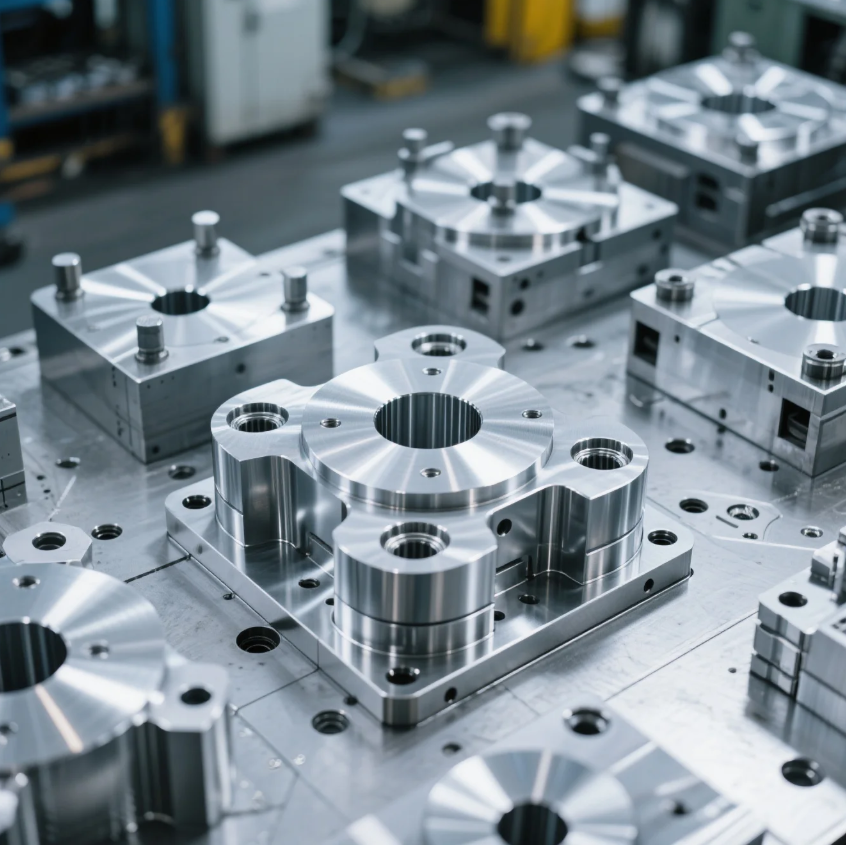

What are the four types of sheet metal working?

Buyers often ask what processes turn flat sheet into working parts.

The four main types of sheet metal working are cutting, bending, drawing, and stamping. Each process has different goals.

These methods define how the metal transforms. Cutting divides the sheet. Bending changes its shape. Drawing stretches it into a form. Stamping uses high force to shape it in one press. At Prime, we combine these techniques to meet precise design needs. Whether you need stamped components or drawn parts, we deliver with speed and precision.

Main Sheet Metal Working Processes

| Process | Description | Common Tools Used |

|---|---|---|

| Cutting | Separates sheet into parts | Shears, lasers, punches |

| Bending | Forms angles or curves | Press brakes, rollers |

| Drawing | Pulls sheet into a die to form shapes | Deep draw presses |

| Stamping | Presses patterns using dies | Hydraulic presses |

By managing these in-house, we reduce lead times and maintain full quality control for clients in every industry.

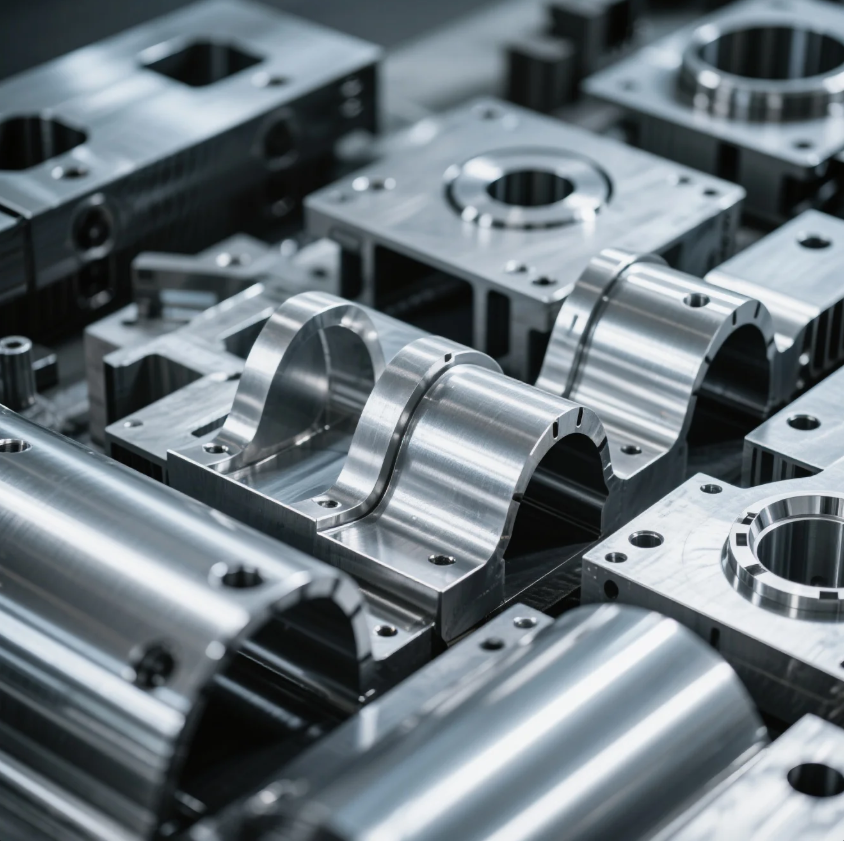

Which metals are commonly used in sheet metal work?

Each project needs different metal properties. Choosing the right one saves time and cost.

The most commonly used metals in sheet metal work are mild steel, stainless steel, aluminum, and copper. Each suits different environments.

Mild steel is great for low-cost indoor use. Stainless steel resists rust and suits harsh conditions. Aluminum is light, corrosion-resistant, and good for transport or electronics. Copper is expensive but offers electrical conductivity and weather durability. At Prime, we help clients match the metal to their project’s goals, location, and budget.

Common Sheet Metal Types and Their Uses

| Metal | Key Traits | Common Applications |

|---|---|---|

| Mild Steel | Cheap, strong, weldable | Brackets, structural parts |

| Stainless Steel | Rust-proof, strong, clean surface | Food machines, outdoor parts |

| Aluminum | Lightweight, rust-resistant | Housings, panels, electronics |

| Copper | Conductive, high corrosion resistance | Electrical, roofing, decoration |

We keep these metals in stock for fast turnaround. Our global clients count on our CNC part accuracy and quick shipping.

Conclusion

Common sheet metals like steel and aluminum offer strong, affordable, and flexible solutions.

Need help choosing the right sheet metal? Contact Prime today for a free consultation and competitive quote. We deliver globally, offer ISO-certified quality, and ship fast—no matter your industry or volume.