What Are the Names of the 10 Metallic Minerals?

Metallic minerals are essential for various industries, but understanding their types can be overwhelming. In this article, we will break down the 10 most important metallic minerals, explore their characteristics, uses, and industrial relevance, helping you understand how they contribute to modern-day manufacturing and production.

Snippet paragraph: In this article, we will explore the 10 key metallic minerals, helping you understand their types, uses, and industrial relevance.

Transition paragraph: Let’s dive deeper into the names and characteristics of the most crucial metallic minerals, highlighting their importance in the industrial world.

What Are the 10 Metallic Minerals?

Metallic minerals are the backbone of many industries. They are natural resources that contain metals in their raw form, which can be extracted through mining and processed for various applications. These minerals are often abundant, but their uses are specialized based on the type of metal they contain.

Snippet paragraph: Metallic minerals are mined for the extraction of metals. These minerals include iron, copper, gold, and more, each crucial for specific industrial applications.

List of the 10 Metallic Minerals

-

Iron Ore

Iron ore is one of the most important and widely used metallic minerals. It is the primary source of iron, which is later used to make steel. Steel is a fundamental material used in almost all industries, including construction, automotive, and manufacturing. Iron ore is mined in large quantities, and after extraction, it undergoes a process known as smelting to convert it into usable iron. -

Copper

Copper is a highly versatile metallic mineral known for its excellent electrical conductivity. It is a critical material in the electronics and electrical industries, where it is used for wiring, motors, and electrical components. Copper is also used in plumbing systems, roofing, and industrial machinery. Over time, copper has remained one of the most reliable metals due to its high resistance to corrosion. -

Gold

Gold is a precious metal valued for its rarity, beauty, and durability. It is primarily used in jewelry, where it symbolizes wealth and luxury, but it also has significant industrial uses. Gold is a great conductor of electricity and is often used in high-end electronics, such as smartphones and computers. Additionally, gold serves as a form of investment, being a reliable store of value in uncertain economic times. -

Silver

Silver shares many similarities with gold, including its use in jewelry and as a store of wealth. However, it is much more affordable and is highly valued for its use in electronics, batteries, and solar panels. Silver is also used in photography and various industrial processes, especially where high electrical conductivity and reflectivity are necessary. -

Aluminum

Aluminum is one of the most important non-ferrous metals used in modern industries. It is lightweight, durable, and highly resistant to corrosion, making it ideal for use in the aerospace, automotive, and construction industries. Aluminum’s strength-to-weight ratio allows for its use in products ranging from airplanes to packaging materials. It is also highly recyclable, which makes it a sustainable material choice. -

Lead

Lead has long been used in batteries, particularly in the production of lead-acid batteries for vehicles and backup power systems. Lead is also known for its use in radiation shielding and soundproofing materials. Despite its toxicity, lead still plays a crucial role in many industrial processes, particularly in the energy sector, where it is used in battery storage systems. -

Zinc

Zinc is primarily used in galvanizing steel, a process where steel is coated with a layer of zinc to prevent rusting. This makes zinc essential in industries where corrosion resistance is key, such as in construction and transportation. Zinc is also used in the production of various alloys, including brass, and in the manufacture of rubber, paints, and fertilizers. -

Nickel

Nickel is a crucial material in the production of stainless steel, an alloy made with chromium and nickel. Stainless steel is highly resistant to corrosion and is used in a variety of industries, including food processing, healthcare, and construction. Nickel is also used in the production of rechargeable batteries, including those used in electric vehicles and consumer electronics. -

Tin

Tin is used as a coating for other metals, particularly in the food and beverage industry for cans. It is also a key component in soldering materials for electronics. Tin’s ability to resist corrosion and its low melting point make it ideal for these applications. It is also used in producing various alloys, including bronze, which has been used for thousands of years in tools and weapons. -

Platinum

Platinum is a rare and valuable metal that has significant uses in catalytic converters for cars, which help reduce harmful emissions. It is also used in jewelry and electronics, where its resistance to corrosion and high melting point make it an ideal material. Platinum is a key metal in the chemical industry, where it is used as a catalyst in various reactions.

Summary of Key Characteristics

| Mineral | Common Uses | Primary Application |

|---|---|---|

| Iron Ore | Steel production | Construction, automotive |

| Copper | Electrical wiring, plumbing | Electronics, construction |

| Gold | Jewelry, investment, electronics | Luxury goods, electronics |

| Silver | Jewelry, electronics | Currency, jewelry |

| Aluminum | Lightweight structures, packaging | Aerospace, manufacturing |

| Lead | Batteries, radiation shielding | Construction, automotive |

| Zinc | Rust prevention, alloys | Galvanizing steel |

| Nickel | Stainless steel, rechargeable batteries | Electronics, battery technology |

| Tin | Coating metals, soldering | Electronics, construction |

| Platinum | Catalysts, jewelry | Automotive, electronics, jewelry |

LOOP_END

What Are the 10 Most Common Minerals Called?

While metallic minerals are the focus here, it’s also essential to know about the most common minerals found in the earth’s crust. These minerals are often referred to as the "building blocks" of geology. They can be classified as either metallic or non-metallic. The common metallic minerals that we already discussed, such as iron and copper, are among the most abundant. However, non-metallic minerals like quartz and feldspar also play significant roles in construction and industrial uses.

Snippet paragraph: The 10 most common minerals include both metallic and non-metallic types, with each having significant industrial applications.

Common Metallic Minerals

In addition to the 10 we have covered, here are other notable metallic minerals that you may encounter in various industries:

- Manganese: Important for producing steel and batteries.

- Chromium: Used in making stainless steel and other alloys.

- Titanium: Known for its strength and corrosion resistance, often used in aerospace and medical applications.

These minerals are often found together with other metals, and their mining and processing are critical to a wide range of industrial applications. The mining industry is constantly exploring new ways to extract these metals efficiently and sustainably, ensuring a steady supply for industries across the globe.

What Are the 20 Metal Ores?

Metal ores are naturally occurring rocks or minerals that contain metal elements in sufficient quantities to make extraction feasible. Understanding the difference between a metallic mineral and a metal ore is crucial for industries that rely on mining. The ores are extracted and then refined into usable metals. Here are 20 significant metal ores:

- Bauxite (Aluminum)

- Hematite (Iron)

- Chalcopyrite (Copper)

- Galena (Lead)

- Zincite (Zinc)

- Cassiterite (Tin)

- Platinum Ore (Platinum)

- Manganite (Manganese)

- Chromite (Chromium)

- Magnetite (Iron)

- Cinnabar (Mercury)

- Gold Ore (Gold)

- Nickel Ore (Nickel)

- Silver Ore (Silver)

- Titanite (Titanium)

- Rutile (Titanium)

- Spinel (Magnesium)

- Sphalerite (Zinc)

- Tungsten Ore (Tungsten)

- Molybdenite (Molybdenum)

These ores undergo various extraction processes to separate the metal from the rock. The extraction techniques vary depending on the mineral’s properties, and the metals are then used in numerous industrial applications.

Conclusion

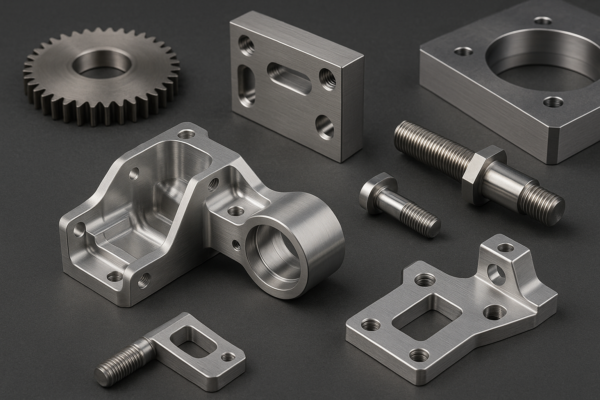

Understanding the different metallic minerals and their ores is essential for anyone involved in the manufacturing, mining, or industrial sectors. Whether you’re sourcing raw materials or looking to optimize your production processes, the right knowledge can ensure high-quality results. At Prime, we understand the importance of metal sourcing and supply chain management. We offer top-quality parts for all your industrial needs, ensuring swift delivery and consistent quality.

If you’re interested in learning more or sourcing metal parts for your projects, feel free to contact us for a free consultation, quote, and customized solutions. Our team is ready to support your business with reliable, high-quality materials to meet your production deadlines.