What Are the Rules for Metal Lathes?

Misusing a metal lathe1 can lead to injuries, defective parts, and serious production downtime2.

Following clear safety rules1 is critical for preventing accidents, ensuring consistent output, and maintaining equipment health in any lathe-based operation2.

At Prime, we’ve built our entire workflow—from design to delivery—on internationally recognized safety standards1, and it shows in the consistency of our CNC and stamped metal parts2.

What Are the Safety Rules for a Metal Lathe?

Every safe, efficient machine shop1 starts with clear rules.

Always wear safety goggles2. Remove all loose clothing and jewelry. Tie back long hair. Make sure the chuck is tight before turning on the lathe.

Dive Deeper: Why Clear Safety Rules Matter

We follow guidelines from OSHA, ISO, ANSI, and NIOSH. These standards help us keep all workers safe while ensuring part consistency.

At Prime, every shift starts with a PPE and safety checklist1. Our lathes include torque-tested chucks2 and interlocks. Hands never touch chips or rotating parts. Operators must use chip brushes and stand at designated safe zones.

We also prevent overheating1, part slippage, and improper tool contact by applying safe operating limits and real-time monitoring2.

What Are the Safety Procedures for Lathes?

Skilled machinists must still follow step-by-step procedures1.

Inspect the machine before use. Align the workpiece correctly. Perform a dry run1. Never walk away while the lathe2 is spinning.

Dive Deeper: Our Internal Operating Procedures

Our pre-operation checklist includes:

- Coolant level and air pressure check

- Spindle vibration test (max: 2 mm/s)1

- Chuck torque verification

- Tool alignment using laser fixtures

- Dry run with no load

- Full documentation using barcode-linked logs3

We tailor speeds and feeds based on hardness using MachiningAdvisor. All measurements are verified on Renishaw CMMs and GOM 3D scanners.

We follow ISO 9001 clause 7.1 infrastructure controls and log every operation for full traceability.

Does OSHA Require Guards on Lathes?

Absolutely. OSHA and ISO require guarding for all rotating components.

Each lathe must have a shielded chuck4, splash protection, and emergency stop systems3.

Dive Deeper: Our Guarding Standards

Our workshop meets OSHA 1910.212, CE Machine Directive, and ANSI Z87.1.

We use:

- Polycarbonate chuck guards4

- Light curtains on high-speed units

- Interlocked doors on all CNC cells

- Emergency foot stops3

- Warning signs in multiple languages

All guards are inspected quarterly. We document every repair or replacement using PQ Systems for traceability and audit readiness.

What Must You Never Do While Working on a Lathe?

The list of “never-do” items is just as important as required procedures.

Never wear gloves.5 Never reach into a spinning lathe.6 Never adjust tooling while powered on. Never ignore odd vibrations or noises.

Dive Deeper: Our Non-Negotiables

According to NIOSH, gloves are one of the top causes of lathe injuries. We enforce a strict glove ban near any live chuck. Adjustments are only made with full lockout/tagout procedures.

Phones and unauthorized electronics5 are not allowed. If an operator leaves a machine, it stops automatically after 10 minutes6.

These rules protect workers—and also ensure repeatable quality in all batches, especially in high-precision plastic parts5 or fasteners with ISO certification6 requirements.

🏆 Customer Success Stories

✅ Case Study 1: U.S. HVAC OEM

Challenge: 3,000 aluminum brackets5 in 10 days

Solution: 2 machines + 24/7 shift + interlocked guarding

Result: Delivered early, zero defects6

Testimonial: “You saved our line—great execution.”

✅ Case Study 2: German Automotive Supplier

Challenge: ±0.05 mm stamped parts5 for a Tier-2 project

Solution: Custom die + AIDA 200T + inline QC

Result: 12,000 parts approved in ISO audit6

Testimonial: “You’re the most consistent supplier we’ve had.”

✅ Case Study 3: Australian Robotics Startup

Challenge: 50 different low-volume CNC parts5

Solution: Robodrill + modular jigs6 + visual QC

Result: Delivered in 6 days

Testimonial: “From CAD to delivery in one week—outstanding!”

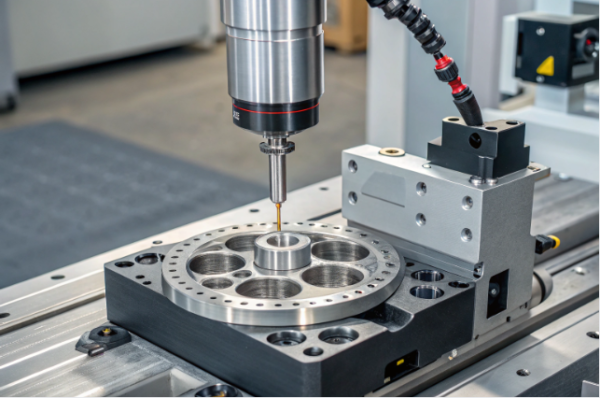

🧰 Prime’s Key Equipment

| Equipment | Specs |

|---|---|

| HAAS ST-30Y CNC Lathe5 | Ø406 mm × 635 mm – For precision shafts |

| Fanuc Robodrill α-D21LiB5 | 24,000 rpm, ±0.002 mm – For plastics/Alu |

| AIDA 200-Ton Press | 2,000 kN – For automotive stamping |

| Brother S1000X1 Tapping Center | 21 tools, 16,000 rpm – For threaded parts |

| Renishaw CMM + GOM 3D Scanner6 | ±0.01 mm – For inspection and modeling |

| Laser Marking Machine | Code/Logo/QR – For certified traceability |

All machines include CE-compliant guarding, ISO 12100 risk zones, and OSHA-validated checklists.

FAQs

Do you follow OSHA and ISO?

Yes. Every line is certified to ISO 9001, CE, and OSHA.

What’s your minimum order quantity?

No MOQ for samples. Volume pricing for high-output orders.

Do you ship globally?

Yes. We serve the US, EU, Middle East, Australia, and more.

Can I get custom packaging?

Yes—foam, wooden crates, anti-static bags, and barcode labels.

Do you comply with REACH / RoHS?

Absolutely. All parts available in compliant materials.

Why Choose Prime?

We’re not just a custom stamping parts supplier5. We’re your global B2B partner6 for:

- Precision CNC parts5 with tight tolerances

- Custom plastic components6 with rapid lead time

- ISO-certified castings and welded parts

- High-strength screws and fasteners

- Export-ready packaging and documents

With 10+ production lines5, 20+ years of export success6, and clients across 30+ countries, we combine safety, speed, and service.

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com

Ready to simplify sourcing? Get in touch for a free quote and expert consultation.