What are the steps in stamping?

Stamping turns raw metal into functional parts—but only if the process is precise.

The stamping process involves a sequence of operations such as blanking, piercing, bending, forming, drawing, trimming, and coining.

Each step shapes the sheet metal progressively until the final part is ready.

What are the steps in the stamping method?

Metal parts don’t come from molds—they’re formed step-by-step under pressure.

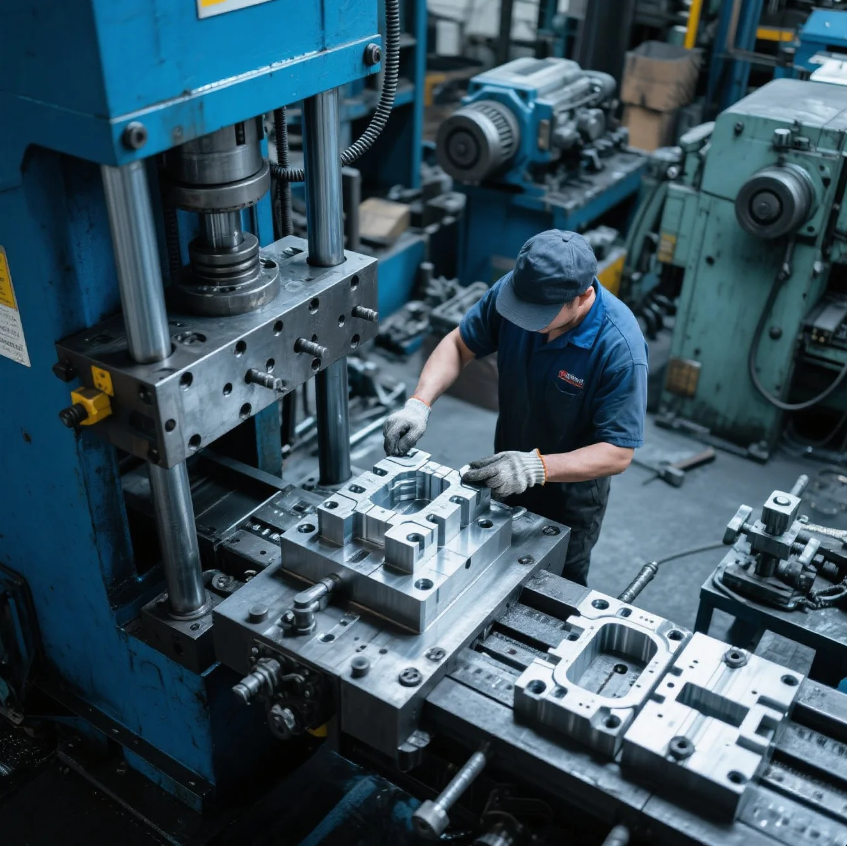

The stamping method uses dies to carry out multiple forming actions on sheet metal. Each stage adds or removes material to create the final shape.

This method is fast, repeatable, and scalable for high-volume production.

7 Key Steps in the Stamping Method

| Step | Function |

|---|---|

| Blanking | Cuts a flat outline from sheet metal |

| Piercing | Punches holes or openings |

| Bending | Forms angles or corners |

| Forming | Creates 3D shapes without cutting |

| Drawing | Stretches material into deep shapes |

| Trimming | Removes excess metal or flash |

| Coining | Imprints detail, logos, or textures |

At Prime, we apply these steps using progressive dies in our high-speed stamping presses—ideal for custom metal components.

What is the stamping procedure?

Stamping isn’t one motion—it’s a complete production cycle.

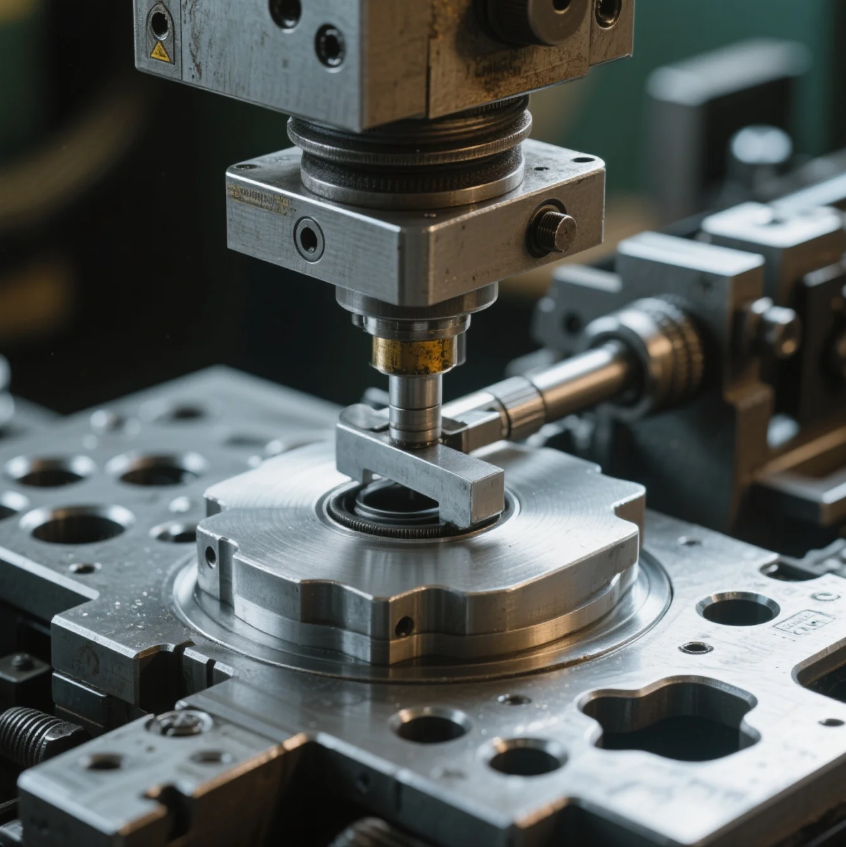

The stamping procedure begins with feeding metal into a press, aligning it with a die, and applying force to shape or cut it.

This cycle repeats rapidly to produce parts with high precision.

Stamping Procedure Sequence

- Metal sheet feeding – Rolled sheet or blank inserted

- Alignment and clamping – Secures metal for precise shaping

- Press action – Tooling contacts and shapes metal

- Ejection – Finished part exits the die

- Repeat – Material advances for next stroke

At Prime, we use automated feeders and tool sensors to streamline this process—delivering fast, consistent output for ISO-certified parts.

What is the operation of stamping?

The operation depends on the part’s design—some need more than cutting or bending.

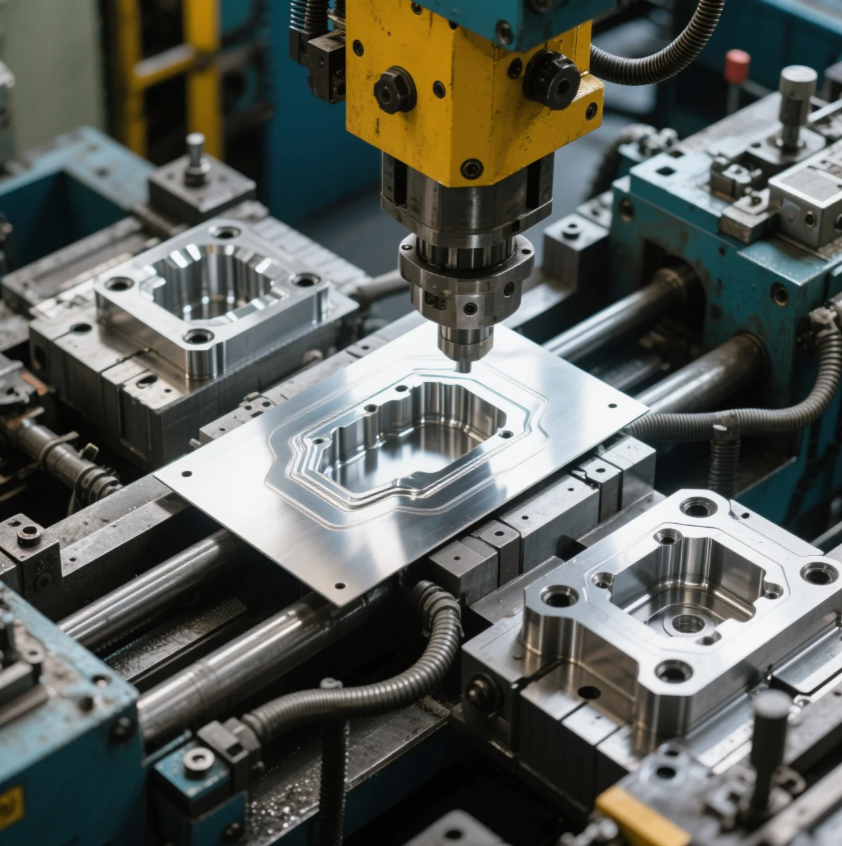

Stamping operations include a combination of forming and cutting techniques that apply force to shape metal without cracking or tearing.

Each operation has its own tooling setup, force requirements, and sequence.

Core Stamping Operations

| Operation | Purpose |

|---|---|

| Cutting | Separates material (blanking, piercing) |

| Bending | Changes angle of the metal |

| Drawing | Pulls material into a mold cavity |

| Coining | Applies detailed impressions |

| Embossing | Raises or depresses surface |

We choose operations based on the material, tolerance, and final use of the part. Every custom stamping project at Prime starts with a detailed process plan.

What is the process of forming and stamping?

Forming and stamping often go hand-in-hand in high-volume production.

Forming involves reshaping the metal without removing material, while stamping includes both forming and cutting processes.

Together, they create complex parts quickly and with high repeatability.

Difference Between Forming and Stamping

| Process | Includes Cutting? | Purpose |

|---|---|---|

| Stamping | Yes | Cutting and shaping parts |

| Forming | No | Reshaping metal with pressure |

At Prime, we use hybrid press lines that combine forming and stamping operations—ideal for automotive parts, brackets, and industrial enclosures.

Conclusion

Stamping involves multiple steps—cutting, forming, and shaping metal into precise, functional components.

Contact Prime today for full-service stamping support, fast turnaround, and certified quality. With 20+ years of experience, 10 production lines, and advanced tooling, we deliver custom-stamped metal parts to industries worldwide.