What Are the Three Types of Clamps?

Many buyers don’t realize clamps vary by function, structure, and force. Using the wrong one can cause poor hold or part damage.

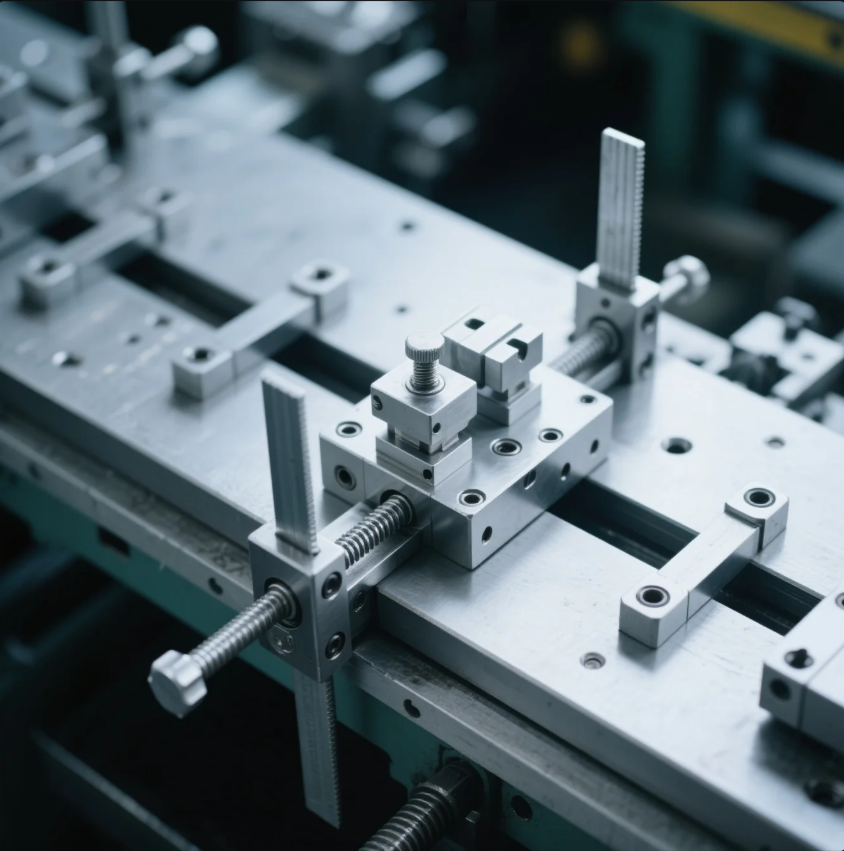

Clamps are tools used to hold objects tightly in place during machining, assembly, or fastening. There are three basic types.

At Prime, we’ve supported clients across manufacturing, woodworking, and construction by supplying the right clamp for their use. Let’s look at the three main clamp categories and their applications.

What Are the Different Types of Clamps?

The term “clamp” covers many tools—but most fall into three functional categories.

The three major types of clamps are: mechanical clamps, pneumatic clamps, and hydraulic clamps.

Each type uses a different power method and serves different force or automation needs.

Primary Clamp Categories

| Clamp Type | Activation Method | Best Use |

|---|---|---|

| Mechanical Clamp | Manual, lever, screw | General workshops, fixtures |

| Pneumatic Clamp | Air pressure | Fast-paced automation lines |

| Hydraulic Clamp | Fluid pressure | Heavy-duty, high-force setups |

At Prime, we manufacture mechanical toggle clamps and lever clamps in bulk. For advanced clients, we also supply hydraulic clamping blocks and custom pneumatic arms.

What Are 3-Way Clamps Used For?

Some clients mistake 3-way clamps for triple force clamps—but it refers to joint direction.

A 3-way clamp is used to hold three panels or surfaces together at 90° angles—ideal for furniture frames or box joints.

These clamps are common in woodworking and cabinetry, offering even pressure on corners and frames.

3-Way Clamp Features

| Use Case | Why Use a 3-Way Clamp? |

|---|---|

| Box or cabinet building | Holds corners squarely |

| Frame assembly | Prevents shifting or gaps |

| Joint glue-ups | Applies equal pressure in 3 axes |

We supply heavy-duty 3-way clamps with cast iron bodies, used by B2B furniture factories in Europe and North America.

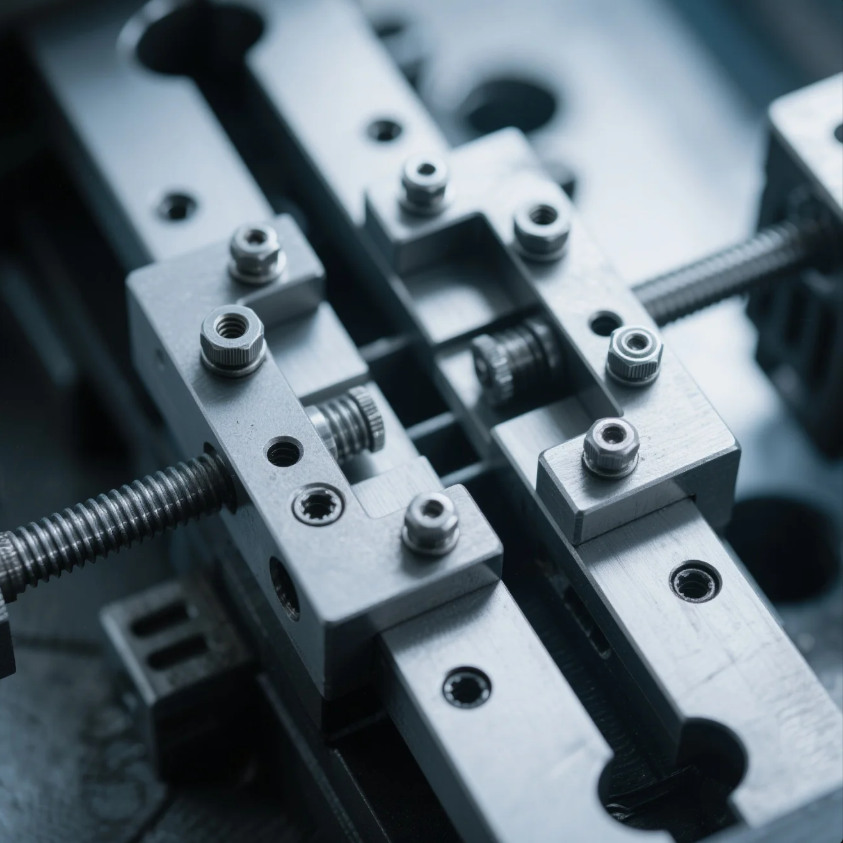

What Are the Three Basic Types of Clamping Units?

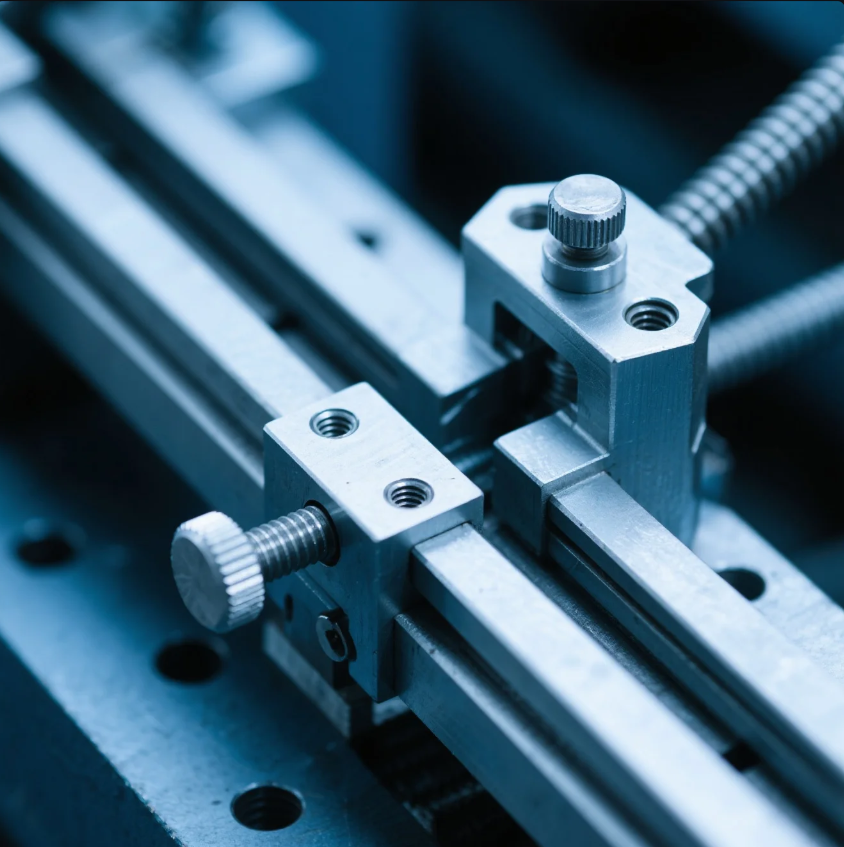

In tooling and machine fixtures, “clamping units” refer to how force is applied and maintained.

The three basic clamping unit types are: fixed clamps, toggle clamps, and quick-release clamps.

Each varies in setup time, hold strength, and operator control.

Clamping Unit Comparison

| Unit Type | Strength | Application |

|---|---|---|

| Fixed Clamp | Very strong | Milling, CNC operations |

| Toggle Clamp | Moderate | Welding jigs, repetitive setups |

| Quick-Release | Light-duty | Tool-free, fast clamping |

Clients using CNC tables often order custom toggle clamps from us with adjustable arm lengths and ISO-standard holes. We also stock quick clamps with push levers for light electronics assembly.

What Are Three Uses of Clamps?

Clamps are more versatile than most buyers think. We often help clients adapt clamp types to unexpected uses.

Three major uses of clamps include: securing parts during machining, holding objects during bonding, and keeping components aligned during assembly.

Common Clamp Applications

| Use | Clamp Role |

|---|---|

| Machining | Holds parts against vibration |

| Gluing or bonding | Maintains contact pressure |

| Positioning/assembly | Aligns parts during fastening |

At Prime, our clamps are used in metal processing, woodworking, electronics assembly, and automation jigs. We also offer custom clamping fixtures for bulk B2B orders.

Conclusion

The three main clamp types—mechanical, pneumatic, and hydraulic—serve different force and precision needs.

Need the right clamps for your production line or fixtures?

At Prime, we supply ISO-grade clamps for machining, assembly, woodworking, and automation.

🔧 Toggle clamps, 3-way clamps, lever clamps, and pneumatic clamp units

📦 Fast production, precise specs, global delivery

🛠 Engineering support to help you choose the right clamping method

📩 Send us your drawings or specs now to get a fast quote and free consultation!