What brazing rod do I use for aluminum?

Choosing the wrong brazing rod ruins joints fast.

Aluminum requires specific rods and techniques for successful brazing—using the wrong setup leads to weak or failed joints.

Here’s how to avoid common mistakes and get perfect aluminum bonds every time.

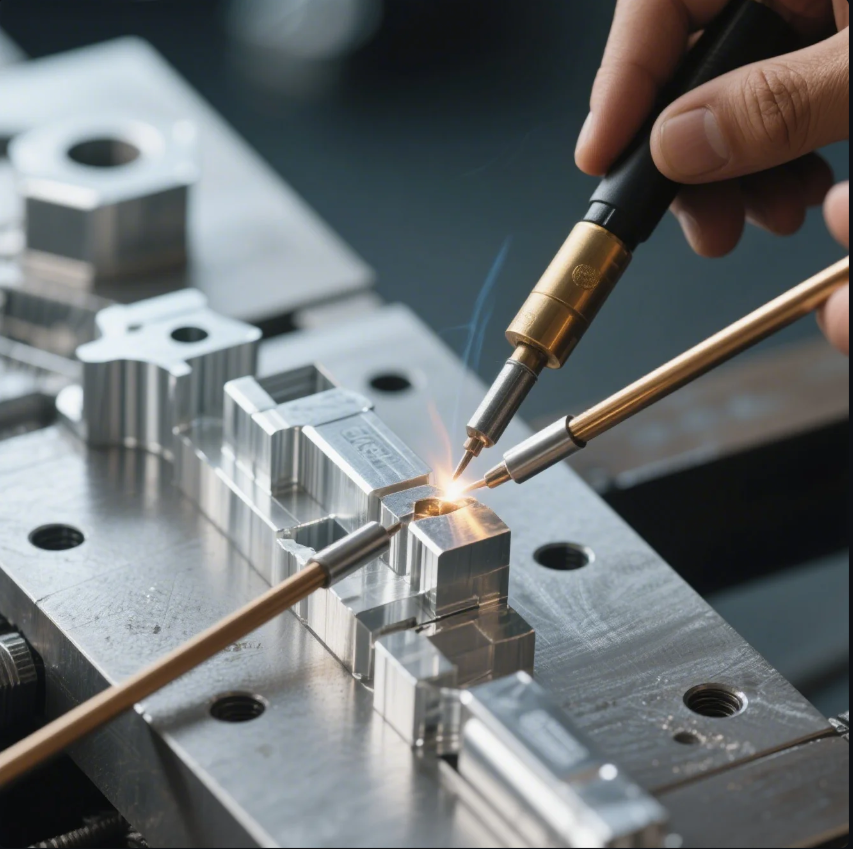

Will brazing stick to aluminum?

Aluminum looks easy—but its oxide layer makes brazing hard.

Yes, brazing sticks to aluminum, but only with the right rods, flux, and surface preparation.

Aluminum forms a stubborn oxide film the moment it contacts air. This layer prevents bonding unless removed. In my early projects sourcing HVAC parts, failed joints traced back to oxide contamination more than anything else.

Why brazing aluminum is tricky

- Aluminum oxide melts above 2000°C.

- Base aluminum melts around 660°C.

- So, the oxide remains solid while the metal flows.

| Property | Aluminum | Aluminum Oxide |

|---|---|---|

| Melting Point | 660°C | 2050°C |

| Appearance | Silvery-white | Transparent film |

| Brazing Compatibility | Only with prep | Must be removed |

How to solve it:

- Mechanically scrub the surface (use stainless steel brush).

- Apply proper aluminum flux.

- Use a rod designed for aluminum bonding.

At Prime, our ISO-certified team ensures every brazing process starts with clean prep and proper filler rods. As a trusted custom stamping parts supplier, we know how to create strong bonds for mass production or precision assemblies.

Do I need flux for aluminum brazing?

No flux, no bond—simple as that.

Yes, flux is essential for aluminum brazing—it removes oxides and allows rods to bond.

I’ve seen clients skip flux to cut costs—only to face premature joint failures. Aluminum oxide reforms quickly. Flux prevents that.

What aluminum brazing flux does

- Dissolves oxide layers on contact

- Prevents further oxidation during heating

- Improves rod wetting and flow

| Type of Flux | Suitable For | Application Form |

|---|---|---|

| Standard Aluminum Flux | General aluminum brazing | Paste, brush-on |

| Pre-Fluxed Rods | High-speed production | Integrated coating |

| Custom Formulas | Complex assemblies | Powder, slurry |

At Prime, we match the correct flux to every filler rod and metal type. Whether you’re ordering bulk parts or trial samples, we ensure your ISO-certified casting parts supplier gives you a worry-free brazing experience.

What rod welds aluminum?

Not all filler rods are created equal.

Use aluminum-zinc or aluminum-silicon rods specifically designed for brazing aluminum.

A U.S. client once sourced random filler rods from a local distributor to save money. Weeks later, cracked joints and returns poured in. That’s when we stepped in to supply pre-tested, alloy-matched rods made for their product line.

Best aluminum brazing rods

| Rod Type | Composition | Application Use |

|---|---|---|

| Aluminum-Zinc (AL4045) | Zn + Al | HVAC, thin tubing |

| Aluminum-Silicon (AL4047) | Si + Al | Automotive, structural applications |

| Multi-Alloy Rods | Varies | Aerospace, precision components |

At Prime, our CNC parts precision machining ensures every rod meets spec. We provide metallurgical reports with every shipment to ensure full traceability and quality.

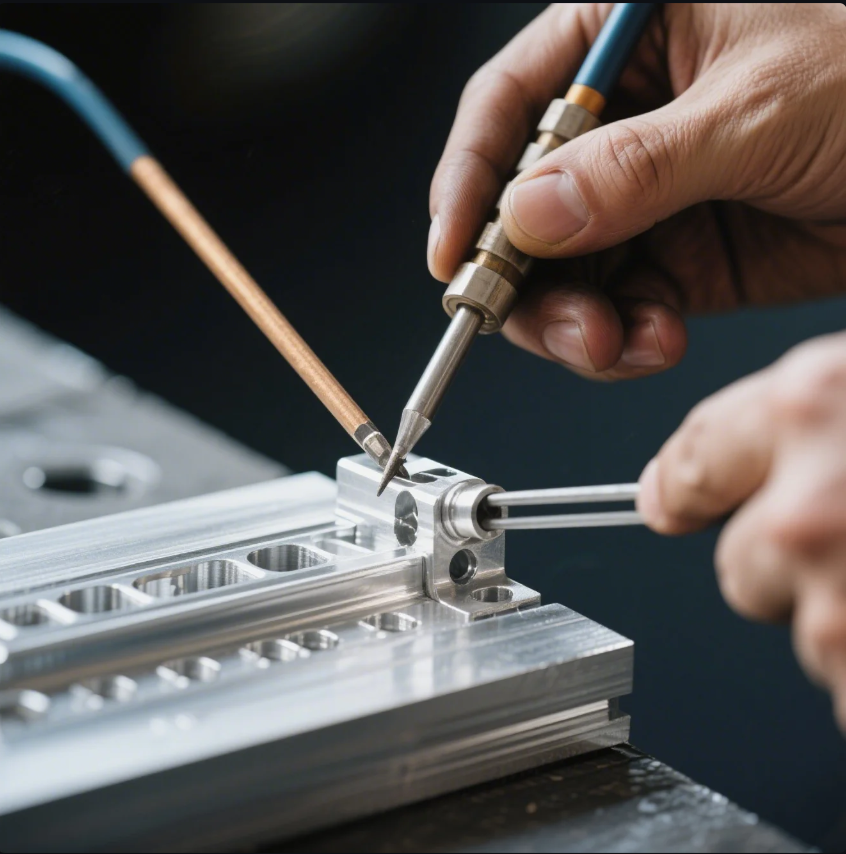

Can I braze aluminum with a propane torch?

Yes—if you manage heat carefully.

Yes, aluminum can be brazed using a propane torch, but only with low-temp rods and even heat.

This question comes up often from small batch producers or on-site repair crews. Propane works fine—but uneven heating causes sagging or burned-through joints.

What to know when using propane

- Use a wide flame to spread heat evenly.

- Preheat thicker parts to balance temperatures.

- Choose rods that melt below 730°C.

- Always apply proper flux before starting.

| Variable | Importance |

|---|---|

| Flame Control | Prevents overheating |

| Rod Temperature | Should melt below 730°C |

| Material Thickness | Affects how fast heat spreads |

| Clean Metal Surface | Ensures strong adhesion |

At Prime, we help clients build systems that fit their tools. Whether you’re using propane or oxy-fuel, we match rods and flux to your process. From aluminum welding to full custom part solutions, we provide technical support beyond the quote.

Conclusion

Choosing the correct rod, flux, and method is key to brazing aluminum successfully.

If you want stronger joints, faster production, and fewer failures, contact Prime today through our website. We offer free technical consultations, fast quotes, and support across all aluminum brazing projects. With ISO-certified quality and fast delivery, we make your job easier and more reliable.