What Cuts Sheet Metal the Best?

A chart of common sheet metal cutting tools and applications.

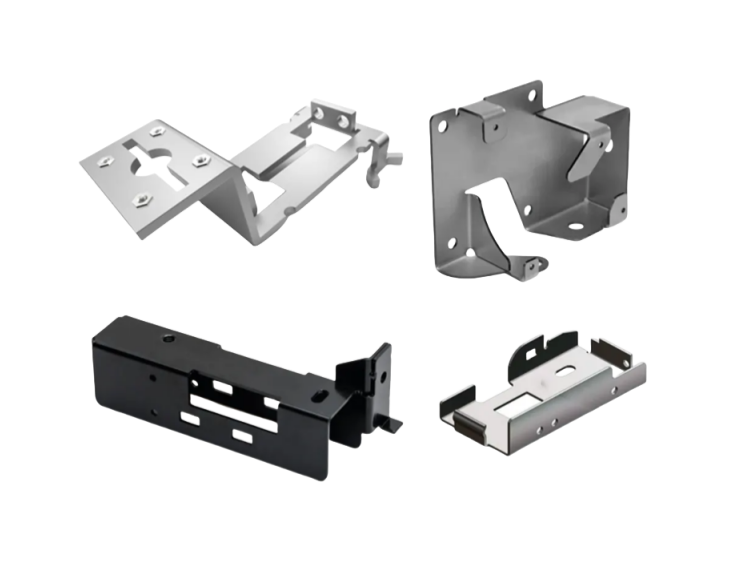

When working with sheet metal, choosing the right cutting method is essential for accuracy, efficiency, and budget. From intricate designs to heavy-duty fabrication, each project calls for a different approach.

Snippet paragraph: What cuts sheet metal the best? The top choices include laser cutters for high precision, plasma for thick steel, and snips for budget jobs. The ideal solution depends on your material, quantity, and tolerance requirements.

Let’s compare the most effective cutting methods used in modern fabrication.

📚 Table of Contents

- What Are the Most Precise Sheet Metal Cutting Methods?

- What Are the Fastest Sheet Metal Cutting Methods?

- What’s the Most Cost-Effective Way to Cut Sheet Metal?

- FAQs

- Contact Prime for a Free Sheet Metal Cutting Consultation

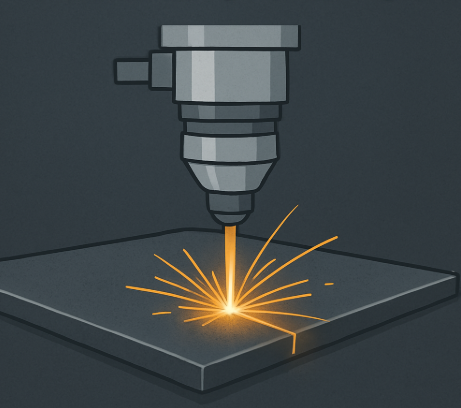

What Are the Most Precise Sheet Metal Cutting Methods?

Precision matters when you’re building parts that must fit perfectly. Some machines outperform others for tolerance and edge quality.

Snippet paragraph: Laser and waterjet cutting provide the highest precision for sheet metal work, offering tight tolerances and clean edges with minimal finishing.

Best Methods for Precision:

-

Laser Cutting

- Accuracy: ±0.005”

- Best for: Medium-thin metals, tight tolerances

- Finish: Smooth, minimal burrs

-

Waterjet Cutting

- Accuracy: ±0.003”

- Best for: Thick materials and heat-sensitive alloys

- Finish: Excellent, no thermal distortion

-

CNC Punching

- Accuracy: ±0.010”

- Best for: Repetitive shapes, holes

- Finish: Moderate, may require secondary deburring

| Method | Max Thickness | Tolerance | Heat Affected? | Finish Quality |

|---|---|---|---|---|

| Laser Cutter | Up to 0.5" | ±0.005" | Yes | Excellent |

| Waterjet | Up to 6" | ±0.003" | No | Great |

| CNC Punch | Up to 0.25" | ±0.010" | Minimal | Moderate |

What Are the Fastest Sheet Metal Cutting Methods?

Speed is critical in high-volume production. Some methods are built for rapid throughput over ultra-fine detail.

Snippet paragraph: Turret punching and plasma cutting are the fastest methods for cutting sheet metal, balancing speed with acceptable edge quality.

Top Speed-Centric Tools:

-

Plasma Cutting

- Speed: Up to 500 in/min

- Best for: Mild and stainless steel

- Heat-affected zone: Yes

-

Turret Punching

- Speed: 600–1000 hits/min

- Best for: Mass-producing parts with holes or cutouts

-

Nibblers

- Speed: Medium

- Best for: On-site adjustments or irregular shapes

| Method | Speed | Ideal For | Limitations |

|---|---|---|---|

| Plasma Cutter | Very Fast | Heavy-gauge steel | Heat distortion, wider kerf |

| Turret Punch | Extremely Fast | Holes, slots, forms | Less suited for thick materials |

| Nibbler | Portable Fast | Field work | Rougher cut quality |

What’s the Most Cost-Effective Way to Cut Sheet Metal?

Not every job needs high-tech equipment. If you’re working on a small batch or prototype, manual and basic tools can go a long way.

Snippet paragraph: Tin snips and throatless shears are budget-friendly tools for cutting sheet metal, while CNC routers offer a mid-range solution for moderate precision and cost.

Low-Cost Cutting Tools:

-

Manual Tools

- Tin snips: \$10–\$50

- Throatless shear: \$100–\$500

- Best for: Light-duty cuts in aluminum or steel

-

Basic Power Tools

- Jigsaw with metal blade: \$100+

- Angle grinder: \$75+

- Bandsaw: \$300–\$600

- Best for: DIY, small fab shops

-

Mid-Range CNC Routers

- Cost: \$\$ to \$\$\$

- Great for: Custom panels, light gauge work

- Materials: Aluminum, brass, copper (not thick steel)

| Tool | Purchase Cost | Ideal For | Skill Needed |

|---|---|---|---|

| Tin Snips | Low | Thin aluminum | Low |

| Throatless Shears | Medium | Curves/edges | Medium |

| CNC Router | High | Mid-precision | High |

| Laser Cutter | Very High | High precision | High |

FAQs

Q1: What’s the cleanest method to cut sheet metal?

A1: Laser cutting produces the cleanest edge with minimal finishing needed.

Q2: Can I cut thick stainless steel at home?

A2: Plasma cutters are ideal for this, but proper ventilation and safety gear are essential.

Q3: What method should I use for curved sheet parts?

A3: Waterjet cutting or throatless shears offer the most control over curves.

Q4: What’s best for a low-volume, tight-budget job?

A4: Tin snips, jigsaws, or throatless shears will handle thin material affordably.

Q5: Does Prime offer laser or waterjet cutting services?

A5: Yes! Prime offers both laser and waterjet cutting, tailored to your tolerance and material needs.

Contact Prime for a Free Sheet Metal Cutting Consultation

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Need guidance on choosing the best cutting method for your metal parts? Prime offers full-service sheet metal fabrication—including cutting, forming, and finishing—all under ISO-certified quality systems.

Conclusion

So, what cuts sheet metal the best? For precision, choose laser or waterjet. For speed, go with plasma or turret punch. On a budget? Use manual tools or entry-level power cutters. The right solution depends on thickness, quality, and cost. Prime helps you pick the perfect fit.