What does a CNC machinist do?

A CNC machinist plays a crucial role in modern manufacturing. But what exactly does a CNC machinist do? In this article, we’ll break down the responsibilities of a CNC machinist, how long it takes to learn the trade, and what kind of salary they can expect.

CNC machinists are essential for creating precise parts used across various industries. Let’s explore their key responsibilities, skills required, and the potential for growth in this field.

At Prime, we work with skilled CNC machinists who ensure that every part meets the highest standards. Let’s dive into what it takes to be a CNC machinist and what the job entails.

What do you do as a CNC machinist?

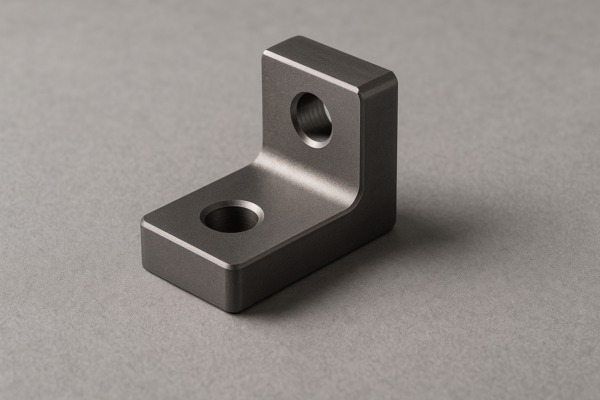

As a CNC machinist, your primary task is to operate CNC machines that cut, shape, and finish materials like metal, plastic, and composites. You are responsible for setting up machines, loading materials, and ensuring that parts are made to exact specifications.

Snippet paragraph: CNC machinists operate machines that cut and shape materials. They set up machines, load materials, and ensure that parts are created to precise specifications.

Machine Operation and Setup

CNC machinists set up and operate CNC machines. This involves selecting the right tools, adjusting machine settings, and ensuring that the machine is working properly. Operators load the material into the machine and monitor the process to ensure accuracy.

- Key Tasks: Setup, tool selection, machine adjustments.

- Responsibility: Ensuring machines work correctly and parts meet design specifications.

Quality Control and Inspection

CNC machinists are also responsible for quality control. They check the dimensions of the parts being made to ensure they meet the required tolerances. This can involve using tools like micrometers and calipers to measure the part’s size and shape.

- Quality Tools: Micrometers, calipers, gauges.

- Task: Ensuring parts meet exact specifications and tolerances.

How long does it take to learn CNC?

Learning CNC machining can take anywhere from several months to a few years, depending on the training program. Formal education programs can last 1-2 years, while on-the-job training may take up to 4 years to master fully.

Snippet paragraph: Learning CNC machining typically takes 1-2 years with formal education. On-the-job training may take up to 4 years to master.

Training and Education

Many CNC machinists start by enrolling in vocational training programs or community colleges that offer hands-on experience with CNC machines. These programs usually cover the basics of CNC operation, blueprint reading, and machine maintenance.

- Training Duration: Typically 1-2 years for formal programs.

- Education: Technical schools, community colleges, or apprenticeships.

On-the-Job Training

While formal education is helpful, much of the learning occurs on the job. CNC machinists gain valuable experience by working with more advanced machines and tackling complex projects. The more time spent in the field, the more proficient they become.

- Training Duration: Apprenticeships and on-the-job experience can take 2-4 years.

- Key Skill Development: Problem-solving, troubleshooting, programming.

Is CNC machinist a hard job?

Being a CNC machinist can be physically and mentally demanding. The job requires attention to detail, strong problem-solving skills, and the ability to work under pressure.

It can be challenging, especially when working with tight tolerances or when troubleshooting machine issues.

Snippet paragraph: CNC machining is a challenging job that requires attention to detail, problem-solving, and the ability to handle pressure, especially when working with complex parts.

Mental and Physical Demands

CNC machinists must focus for extended periods, carefully monitoring machines and checking parts for precision. The job can be physically demanding, as operators may need to lift heavy materials or stand for long periods while working.

- Mental Demands: Attention to detail, focus, troubleshooting.

- Physical Demands: Lifting heavy materials, standing for long periods.

Handling Pressure and Deadlines

Meeting production deadlines and maintaining high-quality standards can create pressure. Mistakes in machining can be costly, and machinists need to stay calm and focused, even under stress.

- Stress Factors: Deadlines, machine errors, tight tolerances.

- Key Skill: Staying focused and calm under pressure.

How much does CNC machining make?

CNC machinists’ salaries can vary based on experience, location, and industry. On average, a CNC machinist earns between \$40,000 and \$60,000 annually. More experienced machinists, particularly those working in specialized industries, can earn upwards of \$70,000.

Snippet paragraph: CNC machinists earn between \$40,000 and \$60,000 annually. Experienced machinists can earn over \$70,000, depending on their skills and location.

Entry-Level vs. Experienced Machinists

Entry-level CNC machinists can expect to earn a lower salary, often starting at around \$40,000 per year. However, as machinists gain experience, their salaries increase. Senior CNC machinists or those in specialized fields can earn \$70,000 or more.

- Entry-Level: \$40,000 – \$45,000 annually.

- Experienced: \$60,000 – \$70,000+ annually.

Geographic and Industry Differences

Location plays a significant role in salary differences. CNC machinists working in areas with higher living costs, such as major metropolitan areas, may earn more. Industries like aerospace or medical device manufacturing tend to pay higher salaries.

- Location Impact: Higher salaries in metropolitan areas.

- Industry Impact: Aerospace and medical industries offer higher salaries.

Conclusion

CNC machinists play a vital role in manufacturing, requiring technical skills, attention to detail, and problem-solving abilities. The job can be challenging but rewarding, with opportunities for growth and specialization.

CNC machinists can expect competitive salaries, with more experienced workers earning higher wages.

At Prime, we rely on skilled CNC machinists to deliver high-quality, precise parts. Contact us today to discuss your next CNC machining project.