What does fasteners mean in mechanical?

In the mechanical world, fasteners are essential components that are used to secure or join two or more parts together. They play a vital role in ensuring the strength, stability, and functionality of mechanical assemblies.

This article will dive into the definition of fasteners in mechanical engineering, their types, and examples of common fasteners used in mechanical systems.

Keep reading to explore the importance of fasteners in the mechanical field.

What are fasteners in mechanical?

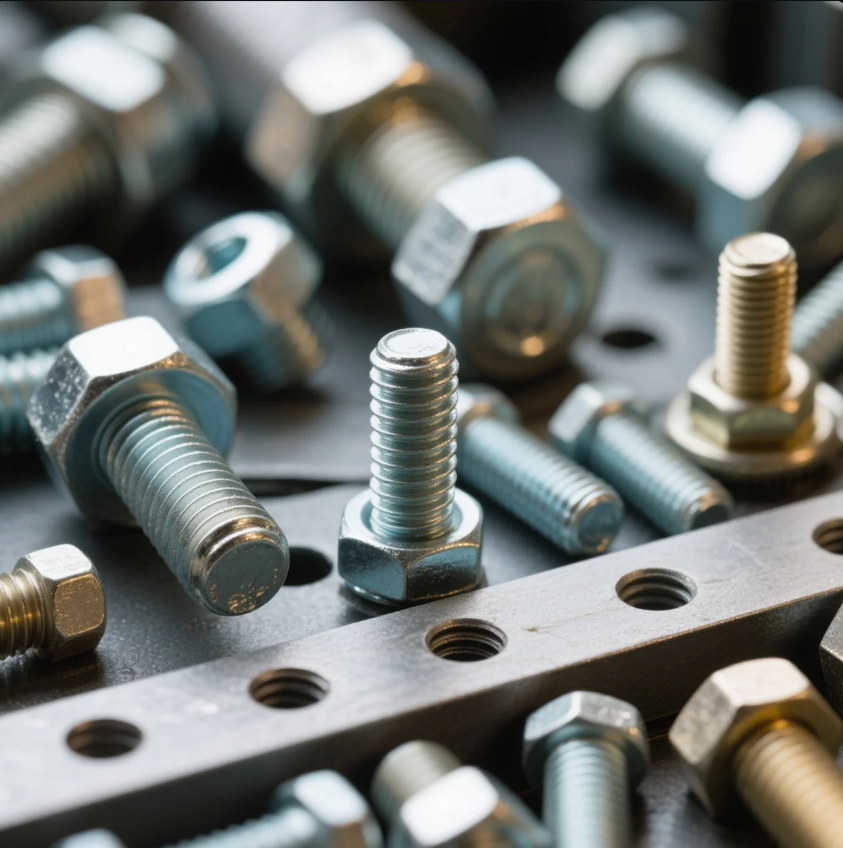

In mechanical terms, fasteners are devices used to connect or hold parts together securely. These can include a wide range of devices like screws, bolts, nuts, rivets, washers, pins, and clips, all of which are used to join components in mechanical systems. Fasteners help ensure that assemblies function correctly and remain stable over time.

Snippet paragraph: In mechanical engineering, fasteners are components like screws, bolts, and pins that are used to secure or join parts together, ensuring stability and functionality in mechanical systems.

Dive-Deeper on Fasteners in Mechanical Systems

-

Screws: Screws are one of the most commonly used fasteners in mechanical systems, offering strong connections for parts that need to be tightly secured. They are used in applications ranging from machinery to electronics.

-

Bolts: Bolts are heavy-duty fasteners used to secure large or heavy components together, often with the help of nuts. They are commonly used in structural components of machinery and vehicles.

-

Nuts: Nuts are paired with bolts and are used to tighten and secure bolts in place. They are commonly used in the automotive and construction industries.

-

Pins: Pins are used to align and hold parts together in mechanical systems, preventing movement. Types of pins include cotter pins, clevis pins, and dowel pins.

-

Rivets: Rivets are permanent fasteners used to secure parts in place without the need for threading. They are widely used in metalworking and aerospace industries.

-

Washers: Washers are placed under bolts and nuts to distribute pressure and prevent damage to the materials being joined. They are commonly used in applications where high pressure or vibration is involved.

Fasteners are critical in ensuring mechanical assemblies function correctly and safely, holding parts in place even under stress.

What do you mean by fasteners?

Fasteners refer to any hardware device or component used to physically join two or more objects together. They are designed to be used in mechanical systems where a permanent or temporary connection is needed. Fasteners can be divided into two categories: permanent (like rivets) and removable (like screws or bolts).

Snippet paragraph: Fasteners are hardware components used to join parts together, either permanently or temporarily, to ensure stability and strength in mechanical systems.

Dive-Deeper on Fasteners in Mechanical Systems

-

Permanent Fasteners: Permanent fasteners like rivets create lasting connections between parts. These are typically used in applications where disassembly is not required, such as in aircraft or bridge construction.

-

Removable Fasteners: Removable fasteners like screws and bolts allow for easy disassembly and maintenance. They are commonly used in mechanical systems that require adjustments or repairs over time.

-

Usage in Industry: Fasteners are used in almost every mechanical industry, from automotive manufacturing to aerospace engineering. They provide the essential link between components, ensuring that machinery and systems operate smoothly.

Fasteners are integral to all types of mechanical assembly, providing both strength and flexibility to different types of systems.

What is an example of a fastener?

An example of a common fastener is a bolt. A bolt is a type of fastener used to join two or more parts together by passing it through a hole in the components and securing it with a nut. Bolts are commonly used in automotive, construction, and machinery applications to provide a strong and durable connection.

Snippet paragraph: An example of a fastener is a bolt, used to connect two parts together by passing it through a hole and securing it with a nut, providing a strong, durable hold.

Dive-Deeper on Examples of Fasteners

-

Bolts: Bolts are widely used in mechanical systems to fasten components that need a strong, secure connection. They come in various sizes and types, including hex bolts, carriage bolts, and lag bolts.

-

Screws: Screws are similar to bolts but are often used in smaller applications or in situations where a more compact fastener is needed. They are available in many different designs, such as wood screws, machine screws, and drywall screws.

-

Rivets: Rivets are used for permanent fastening of materials. They are most commonly used in applications where welding is not practical, such as in metalworking and aircraft assembly.

-

Washers: A washer is a thin, flat disk that is used with bolts or screws to distribute pressure and prevent damage to the surface. They are crucial in applications involving high tension or vibration.

-

Nuts: Nuts are paired with bolts to create a strong fastening connection. They come in various forms, such as hex nuts, wing nuts, and lock nuts, to suit different applications.

These examples represent just a few of the many fasteners used in mechanical engineering and manufacturing to join parts together securely.

What is a fastener in engineering?

In engineering, a fastener refers to any mechanical device that is used to hold or secure two or more parts together. Fasteners are essential in building and assembling machines, vehicles, structures, and other engineered systems. They can be temporary or permanent and are often used in conjunction with other components like screws, bolts, nuts, and washers.

Snippet paragraph: In engineering, a fastener is a device used to join parts together, ensuring strength, stability, and functionality in machines, vehicles, and structures.

Dive-Deeper on Fasteners in Engineering

-

Mechanical Systems: In engineering, fasteners are used in everything from engines to manufacturing systems. They ensure that parts stay securely connected even under high loads or vibrations.

-

Safety and Integrity: Fasteners are essential in maintaining the structural integrity of machines and systems. Whether it’s a simple screw or a complex rivet, these components help ensure that everything remains safely in place.

-

Types of Fasteners: Common fasteners used in engineering include bolts, screws, rivets, washers, and nuts. The choice of fastener depends on the materials being joined, the forces applied to the connection, and whether disassembly will be required.

Fasteners are a fundamental part of the engineering process, providing the necessary connection between components for reliable, long-lasting performance.

Conclusion

Fasteners are vital in mechanical systems, playing a crucial role in joining components securely and reliably. From bolts and screws to rivets and washers, fasteners are indispensable in engineering and manufacturing applications, ensuring safety and durability in machinery and structures.