# What Does It Mean to Jog in CNC? Mastering Machine Movements

Leading paragraph: Confused about jogging vs running a CNC? Discover how this fundamental operation affects your machining workflow.

**Snippet paragraph: Jogging in CNC means manually moving axes using the control panel for setup, while 'Run' executes programmed G-code automatically - both critical for safe operation.**

Transition paragraph: Let's break down jogging mechanics and how it fits into production cycles.

## What Is Jog in a CNC Machine?

Leading paragraph: Jogging is your hands-on control method for precise machine positioning.

**Snippet paragraph: The jog function allows incremental axis movement (typically 0.001"-1.0" steps) using pendant controls or keyboard, essential for tool setup and workpiece alignment.**

Dive-Deeper paragraph:

### Jogging Parameters in Industrial CNCs

#### Common Jog Increments

| Increment Size | Use Case | Button Color (Standard) |

|---------------|----------|-------------------------|

| 0.001" (0.02mm) | Final tool touch | Green |

| 0.010" (0.25mm) | Die alignment | Yellow |

| 0.100" (2.54mm) | Rapid positioning | Blue |

| Continuous | Long travel | Red |

#### Safety Protocols During Jogging

1. **Speed Limits**:

- X/Y Axes: Max 20% rapid rate

- Z Axis: Max 10% rapid rate

2. **Collision Avoidance**:

```plaintext

Jog Sequence:

1. Verify clearance in path

2. Select proper increment

3. Keep finger on Emergency Stop

4. Move smoothly, no sudden stops

```

**Prime's Practice**: Our operators complete 20-hour jog proficiency training before machine access.

## What Does It Mean to Jog a Machine?

Leading paragraph: Beyond simple movement - jogging is about controlled preparation.

**Snippet paragraph: Machine jogging involves manually positioning cutting tools or workpieces using variable feed rates, different from automated operation modes controlled by programs.**

Dive-Deeper paragraph:

### Jogging Application Matrix

#### Setup Procedures Requiring Jogging

| Task | Jog Method | Safety Check |

|--------------------|------------|--------------|

| Tool Length Offset | Z-axis micro | Spindle off |

| Work Coordinate Set | X/Y med. | Probe clear |

| Fixture Alignment | All axes | Clamps secured |

| Crash Recovery | Single-axis | E-stop ready |

#### Jog Speed Comparison Table

| Machine Type | Max Jog Speed | Resolution |

|--------------|---------------|------------|

| Vertical Mill | 100 IPM | 0.0001" |

| Lathe | 60 IPM | 0.0005" |

| Router | 300 IPM | 0.001" |

| EDM | 20 IPM | 0.00005" |

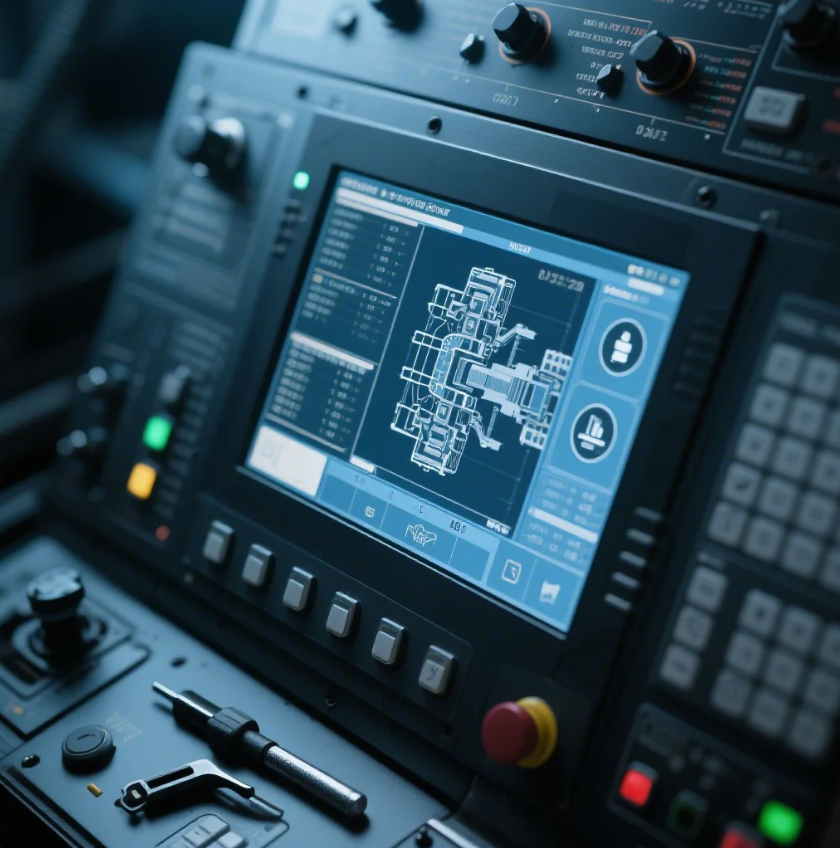

## What Does Run CNC Mean?

Leading paragraph: The transition from manual control to automated precision.

**Snippet paragraph: 'Run' mode executes the loaded G-code program at set feed rates, where the CNC machine autonomously performs all cutting operations without manual intervention.**

Dive-Deeper paragraph:

### Run Mode Execution Process

#### Program Verification Steps

1. **Dry Run**:

- Tools move without cutting

- 50% reduced speed

- Verify all coordinates

2. **Single Block**:

- Execute one line at a time

- Used for critical operations

3. **Full Run**:

- Normal production speed

- Requires first-piece inspection

#### Run vs Jog Performance Factors

| Factor | Jog Mode | Run Mode |

|---------------|----------|----------|

| Speed Control | Manual | Programmed F/S |

| Accuracy | ±0.002" | ±0.0005" |

| Repeatability | Low | High |

| Use Case | Setup | Production |

## What Are the Different Modes of CNC?

Leading paragraph: Your control panel's hidden workflow options revealed.

**Snippet paragraph: Modern CNCs offer 7 operational modes: Jog, MDI, Auto, Edit, Zero Return, DNC, and Emergency Stop - each serving specific phases of the machining process.**

Dive-Deeper paragraph:

### CNC Mode Selection Guide

#### Mode Functionality Matrix

| Mode | Access Level | Primary Use | Axis Movement |

|--------------|--------------|-------------|---------------|

| Jog | Operator | Setup | Manual |

| MDI | Programmer | Test code | Semi-auto |

| Auto | Production | Batch run | Full auto |

| Edit | Supervisor | Code modify | Locked |

| Zero Return | Maintenance | Calibration | Automatic |

#### Safety Interlocks by Mode

```plaintext

1. Jog Mode:

- Requires enabled drives

- Feed hold active

- Spindle interlock

2. Auto Mode:

- Door must close

- Tool offsets verified

- Work coordinates setPrime's Protocol: We implement mode-specific checklists to prevent operational errors.

Conclusion

Master jogging fundamentals to ensure safe, efficient CNC operation.

Need CNC Expertise? Prime's technicians can:

- Provide mode-specific training

- Offer custom jog speed configurations

- Program optimal run parameters

[Contact our CNC specialists] today for operational best practices tailored to your machines and applications.

SEO Keywords:

- "CNC jog vs run mode differences"

- "proper CNC machine jogging techniques"

- "industrial CNC operational modes explained"

- "CNC setup and production workflow"

- "safe CNC machine operation practices"

Image Alt Texts:

- CNC operator demonstrating proper jogging posture

- Close-up of jog increment selection buttons

- Directional jogging reference diagram

- CNC controller in program run mode

- Mode selector switch positions