What Does It Mean to Seal a Joint?

Struggling with leaks or weak spots at material joints? You’re not alone.

Joint sealing protects structures from moisture, dust, and other environmental damage, ensuring durability and strength.

Don’t miss critical tips to avoid costly joint failures.

What is Joint Sealing?

Struggling with unstable joints leading to system failures? It’s a common issue.

Joint sealing means applying materials to close gaps between surfaces, preventing damage and prolonging service life.

Why Joint Sealing Matters for Industrial Components

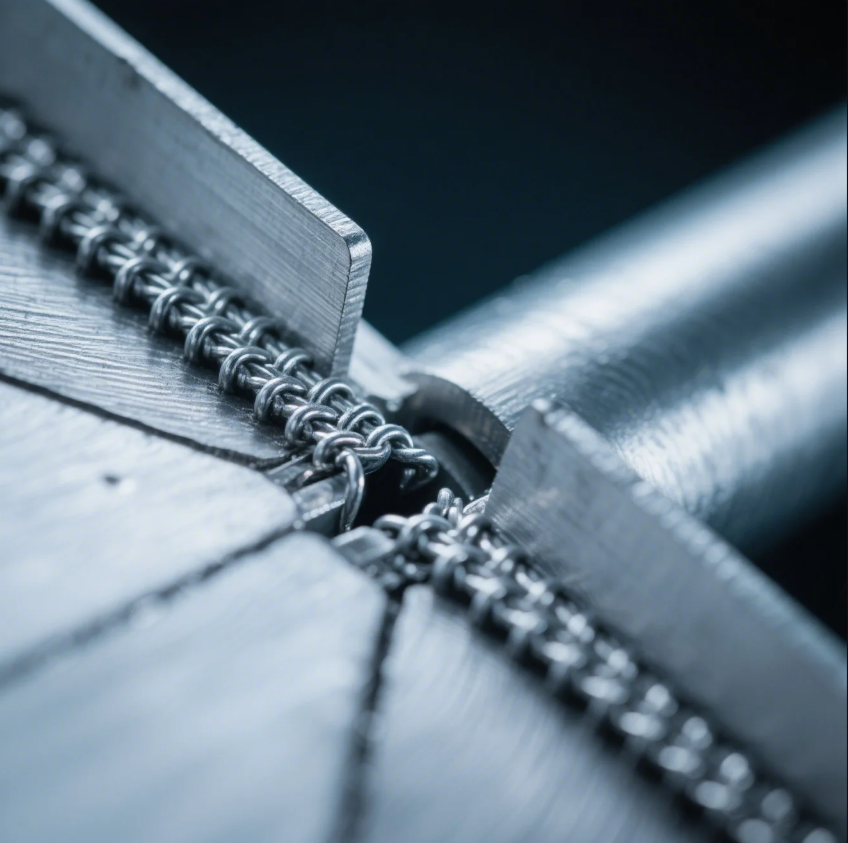

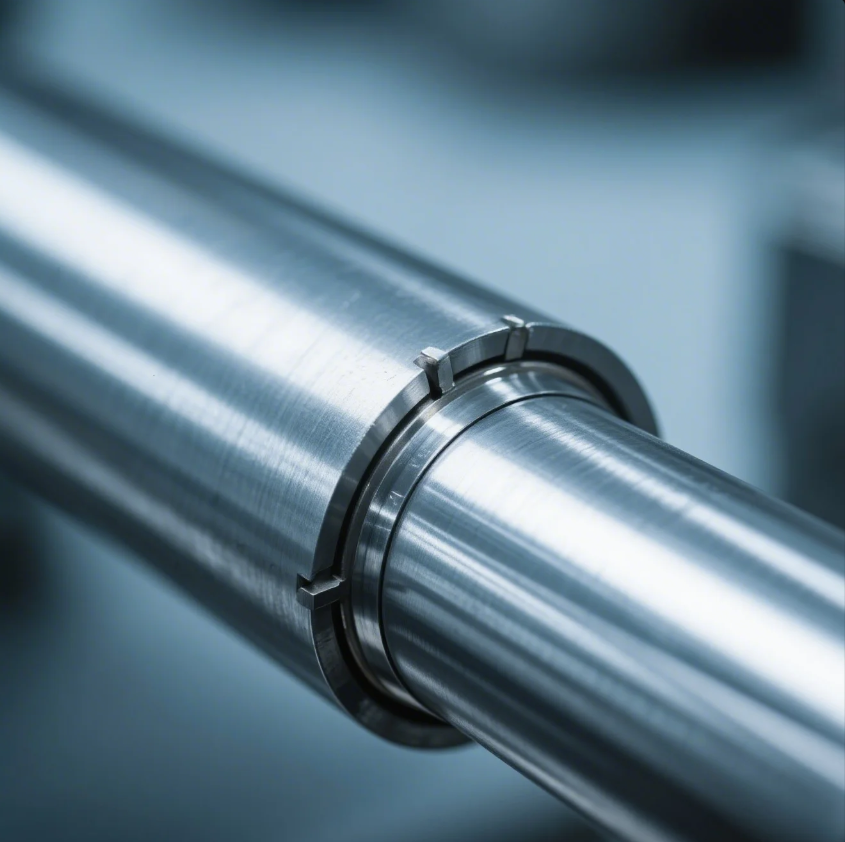

When two metal parts, like CNC parts or stamping parts, meet, they often leave tiny gaps. These gaps invite moisture, dust, and chemicals. Over time, this causes rust, corrosion, and structural weakness. Sealing fills those gaps. It ensures strength, durability, and keeps your assemblies working longer.

At Prime, with over 20 years of expertise in custom stamping parts and ISO-certified casting parts, we understand how critical perfect sealing is in industrial projects.

Common Applications for Joint Sealing

| Application Field | Purpose of Sealing |

|---|---|

| Construction (e.g., metal frames) | Prevents water infiltration |

| Automotive (e.g., body panels) | Protects against vibration and corrosion |

| Aerospace (e.g., aircraft assemblies) | Ensures airtight and watertight seals |

| Industrial Equipment (e.g., CNC assemblies) | Improves operational reliability |

What to Use to Seal Joints?

Choosing the wrong material? It often causes leaks, failures, and costly downtime.

Use appropriate joint sealants like silicone, polyurethane, or epoxy depending on your application needs.

How to Choose the Right Sealant

Not all joint sealing solutions are the same. Different environments need different materials.

Key Factors to Consider:

| Factor | Details |

|---|---|

| Temperature Resistance | For high-heat CNC parts, select temperature-resistant sealants. |

| Flexibility | Joints that move or vibrate require elastic sealants like silicone. |

| Chemical Exposure | Use chemical-resistant sealants for industrial environments. |

| UV Resistance | Outdoor structures need UV-stable sealing materials. |

At Prime, when providing CNC parts with precision machining or plastic parts with custom fits, we always advise clients on the right sealing techniques to match the environment.

What Does a Joint Sealer Do?

Seeing cracking or gaps after installation? Poor sealing often causes this.

A joint sealer prevents environmental elements from penetrating through the joints, ensuring structural performance.

The Critical Role of Joint Sealers

Joint sealers are more than just fillers. They are a defense line. Without a proper sealer, even the best-designed systems fail prematurely.

Main Functions of a Joint Sealer:

| Function | Benefit |

|---|---|

| Water Resistance | Keeps moisture out, avoiding rust or swelling. |

| Movement Accommodation | Absorbs small movements without cracking. |

| Insulation | Seals against temperature, sound, and chemical intrusions. |

| Aesthetic Improvement | Gives a clean, finished look to assembled parts. |

At Prime, when we deliver ISO-certified welding parts or custom CNC machined pieces, we ensure surfaces are prepped for maximum joint sealing efficiency, offering clients peace of mind.

What Material is Used to Seal Joints?

Confused by too many options? Choosing incorrectly can cost time and money.

Materials like silicones, polyurethanes, epoxies, and polysulfides are commonly used for joint sealing.

Detailed Comparison of Joint Sealing Materials

Each sealing material has its strengths and ideal use cases. Picking the right one means longer life for your assembly.

Types of Sealants:

| Sealant Type | Best For | Special Features |

|---|---|---|

| Silicone | Metal-to-metal joints (e.g., CNC parts) | Flexible, waterproof, UV resistant |

| Polyurethane | Construction joints | Strong adhesion, paintable |

| Epoxy | High-load parts (e.g., cast iron joints) | Hard, chemical resistant |

| Polysulfide | Underwater applications | Superior water resistance |

At Prime, whether manufacturing fasteners for critical assemblies or casting parts for heavy industries, we always recommend the best matching sealing strategy, customized to your project.

Conclusion

Sealing joints right improves performance, saves costs, and extends product life.

Need help sealing your next project?

Prime offers top-quality custom stamping parts, CNC parts, and ISO-certified casting parts with expert joint sealing advice. Contact us today through our website for free consultation, custom solutions, and fast delivery. Our trusted quality and on-time service are your best choice for industrial success.