What does stamping do and why is it vital in manufacturing?

Inconsistent parts, high scrap rates, and long lead times are common challenges in manufacturing.

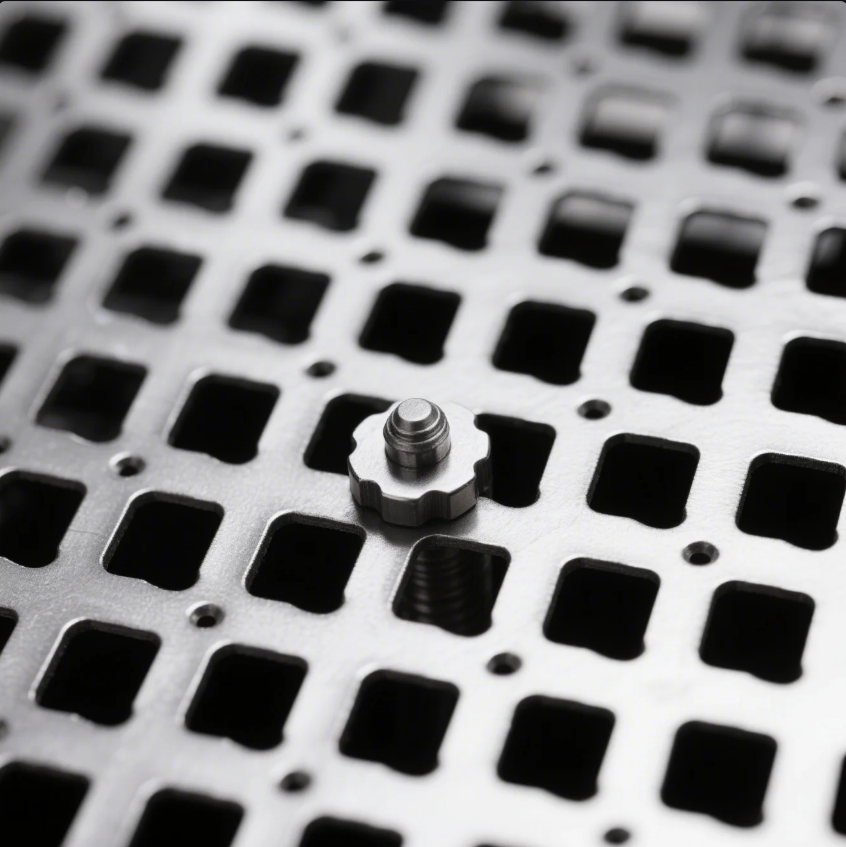

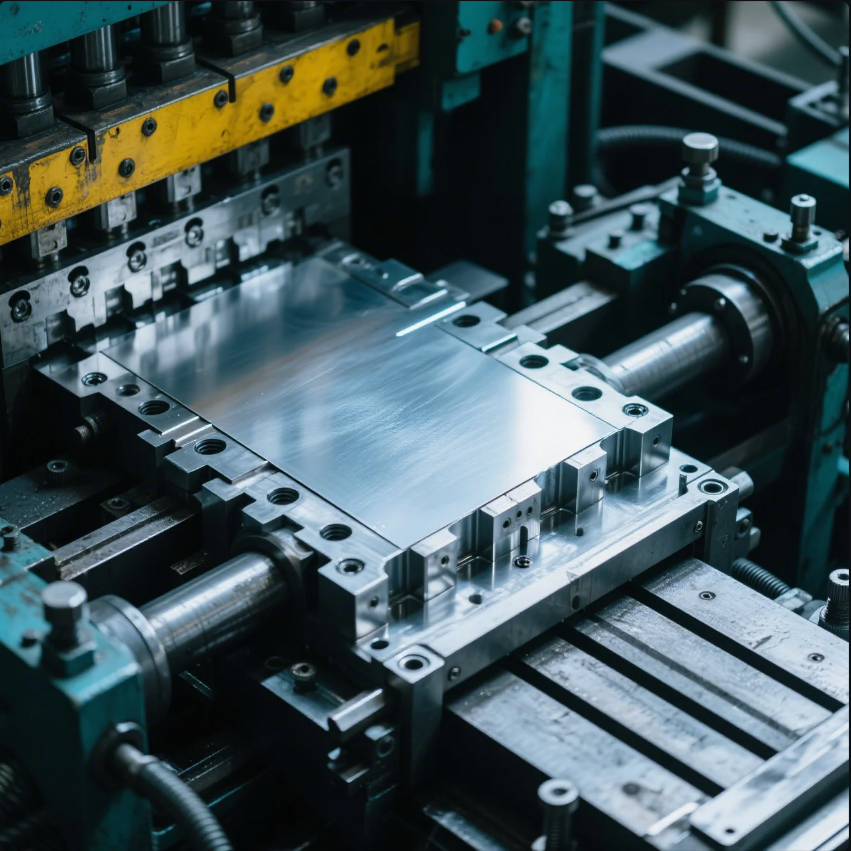

Stamping transforms flat metal sheets into precise, functional parts through controlled pressure and custom dies.

Let’s explore what stamping really does—and why it’s a cornerstone of modern industry.

LOOP_START

What does the stamping process do?

Many assume stamping is just metal cutting—it’s far more powerful and efficient.

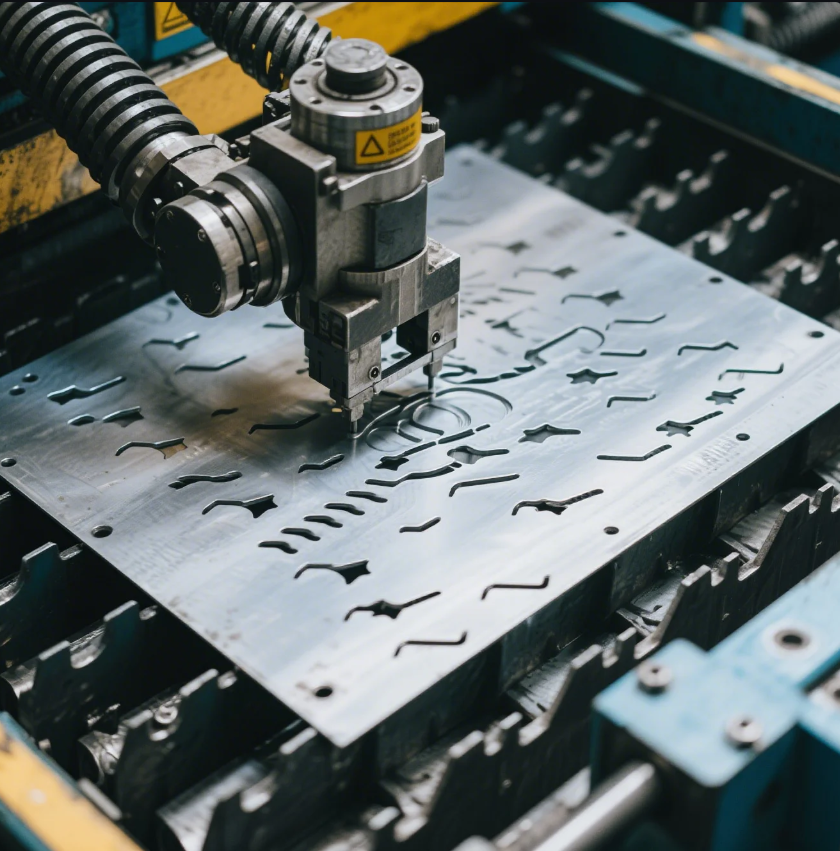

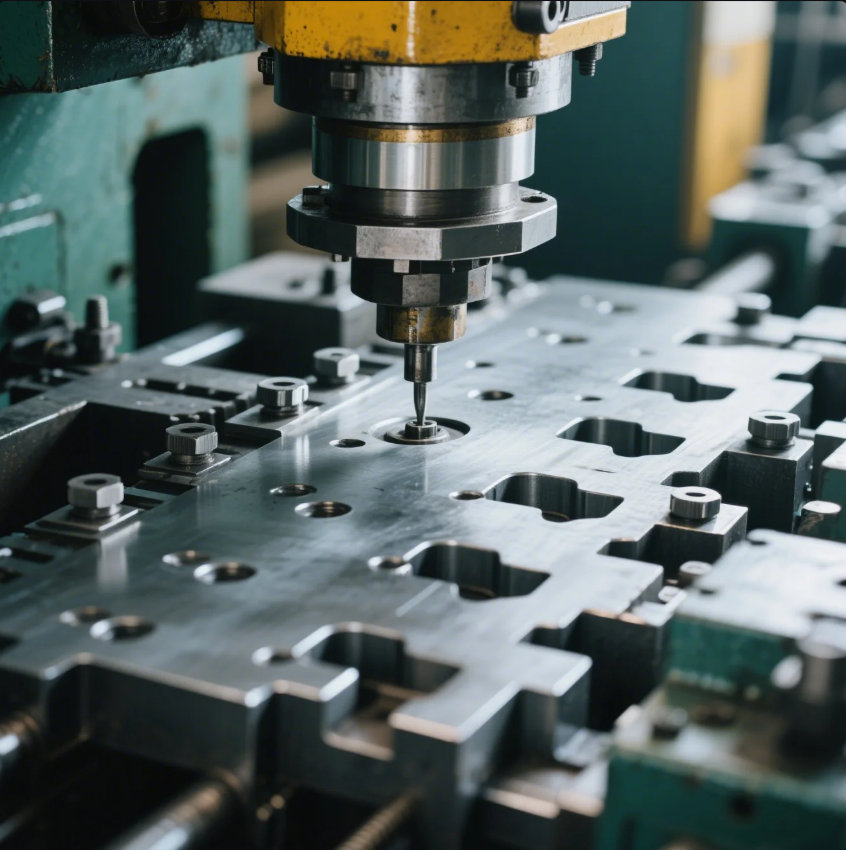

Stamping forms, shapes, cuts, and pierces metal sheets into usable components in a single or multi-step process.

Key actions performed by stamping

| Function | Description |

|---|---|

| Forming | Shapes flat sheets into 3D components using matched dies |

| Piercing | Creates holes, slots, or cutouts |

| Embossing | Adds raised or recessed details for strength or aesthetics |

| Trimming | Removes excess metal or flash after forming |

| Flanging | Bends edges to prepare for joining |

Our approach at Prime

At Prime, we integrate these steps using progressive dies, allowing us to complete multiple actions in one cycle. This reduces cost and cycle time. For a European HVAC client, we produced precision mounting brackets with zero burrs across 250,000 units—delivered in just 21 days.

LOOP_END

LOOP_START

What is stamping in automotive?

Some think automotive stamping is limited to body panels—it’s much broader.

Automotive stamping forms structural, functional, and aesthetic vehicle parts using large metal presses and precision dies.

Common stamped parts in vehicles

| Part Type | Examples |

|---|---|

| Body Panels | Doors, roofs, fenders, hoods |

| Reinforcements | Seat belt brackets, crash impact structures |

| Powertrain Components | Battery supports, engine mounts, transmission brackets |

Why automotive stamping matters

Stamped parts must meet strict size, shape, and strength requirements to ensure vehicle performance and safety. At Prime, we supply both inner structural parts and outer visible panels—all ISO-certified, with support for batch traceability, packaging, and logistics worldwide.

LOOP_END

LOOP_START

What is the reason for stamping?

Factories often switch from casting or manual welding to stamping—why?

Stamping improves efficiency, consistency, and material usage in the mass production of metal parts.

Core benefits of stamping

| Benefit | Impact on Production |

|---|---|

| High Speed | Enables large-scale output with repeatable accuracy |

| Cost Reduction | Lower per-part cost due to rapid cycle time |

| Dimensional Precision | Reduces part variability and assembly issues |

| Material Optimization | Minimal scrap due to precise nesting and die design |

When clients choose stamping

Our clients often switch from CNC or welding when part volumes increase. For example, a U.S. client in the appliance industry replaced 3 welded assemblies with 1 stamped component, cutting costs by 32% and improving delivery time by 40%. Prime handled design conversion and tooling in under 3 weeks.

LOOP_END

LOOP_START

What is the process of stamping a car?

Automotive plants rely on stamping for consistent body and chassis components.

Stamping a car involves a series of controlled forming operations that shape metal into body and structural parts.

Main process steps

| Stage | Action |

|---|---|

| Coil Preparation | Unroll and flatten sheet steel |

| Blanking | Cut the steel into blanks for shaping |

| Forming | Press the blank into 3D shapes using dies |

| Trimming & Piercing | Remove edges and add cutouts |

| Flanging & Finishing | Bend edges and prepare for joining or coating |

How Prime fits in car stamping

We support OEMs and Tier 1 suppliers with parts like chassis brackets, engine mounts, and door stiffeners. With 10 stamping lines, we ensure stable supply and consistent specs—even for large volumes. Our packaging and QC standards meet global automotive requirements.

LOOP_END

Conclusion

Stamping delivers precise, efficient, and scalable metal part production—essential for automotive, industrial, and consumer applications.

Need help with high-volume metal stamping? Contact Prime today for a free expert consultation, competitive quote, and fast, ISO-certified production—trusted by manufacturers worldwide.