What drives custom metal parts cost and how should you maintain stainless steel sheets?

Late changes, rejects, and corrosion waste budget1. Clear cost drivers and simple care rules stop that. This guide aligns specs, cutting, finishing, and day-to-day maintenance so stainless sheets2 deliver predictable quality and total cost.

Custom metal parts cost hinges on material grade (304 vs 316)1, thickness, tolerances/flatness, cutting method, finish (2B/BA/No.4), quantity, QA/tests, and export packaging. Maintenance tips: use neutral detergents, avoid chloride/bleach cleaners, rinse thoroughly, dry, and passivate heat-tinted or machined edges per ASTM A967/A380.

I’ll map how to spec and buy 304 sheets1, control cut-to-size quality, and keep thin gauges clean and corrosion-resistant2 in service.

Shop 304 Stainless Steel Sheet and Plate Metal Products?

Wrong grade/finish or missing standards1 cause rework. Specify the right document, finish, and weld plan2 before you buy.

Specify ASTM A2401 for 304/304L2 sheet and plate, and state the finish (2B, BA, or No.4) on the PO. Choose 304L2 for weld-heavy builds to reduce sensitization risk. In chloride-splash or coastal environments, consider 316; molybdenum improves pitting resistance versus 304.

Dive Deeper

Standards, finishes, and grade selection that cut total cost

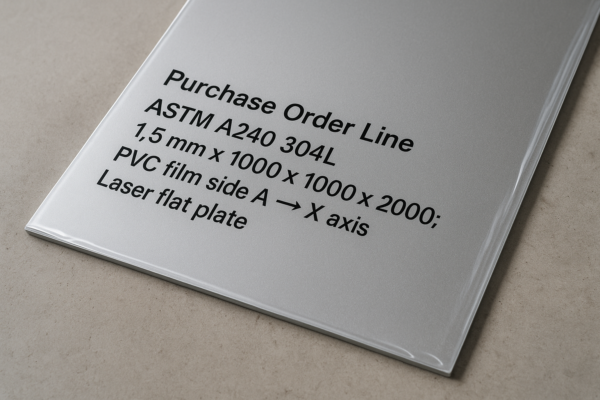

I write POs this way: “ASTM A2401, 304 or 304L, thickness, width/length, finish 2B/BA/No.4, with protective film on A-face.” A240 aligns mills, service centers, and fabricators on chemistry and mechanicals for stainless sheet/plate. Calling out finish avoids substitutions and re-polishing later. For hygienic interiors or equipment panels, 2B or BA clean faster; No.4 hides scuffs but holds soils, so cleaning cycles increase. For welded work, 304L’s low carbon2 reduces sensitization risk; after welding, plan cleaning and passivation so heat tint doesn’t become a corrosion hotspot. If you expect road salt, brine, or sea spray, 316’s molybdenum boosts resistance to pitting and crevice corrosion, reducing warranty risk and unplanned maintenance. Document grain direction if you’ll brush or graining after forming; mismatched grain draws the eye.

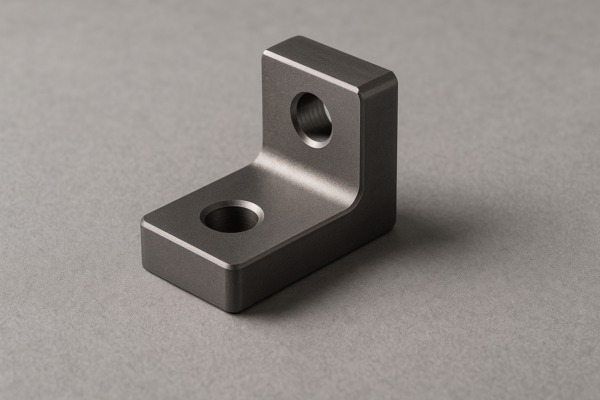

As a manufacturer (Prime, China; ISO-certified; 10 production lines), I combine DFM with sourcing: minimum inside radii1 by gauge, hole-to-edge spacing, and grain direction to avoid swirl marks and “orange peel” after forming. For cosmetic parts I ship finish coupons and run a quick FAI2 so the first panel fits.

Micro-CTA: Upload your drawing for a 24-hour DFM review1 and firm quote2.

Practical checkpoints buyers should verify

- PO states ASTM A240, grade (304/304L), thickness, and finish (2B/BA/No.4). ([ASTM International | ASTM][3])

- Grain direction and protective film1 across cutting, bending, and assembly.

- Weld plan (prefer 304L2 for heavy welds) plus post-weld cleaning/passivation steps.

Quality & packaging notes buyers care about

- Request mill test cert + FAI/CMM1 for assemblies.

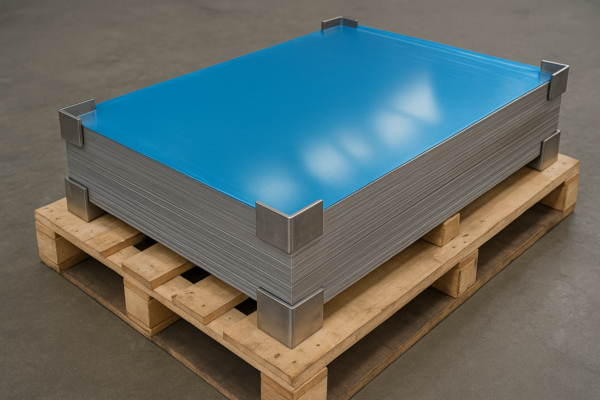

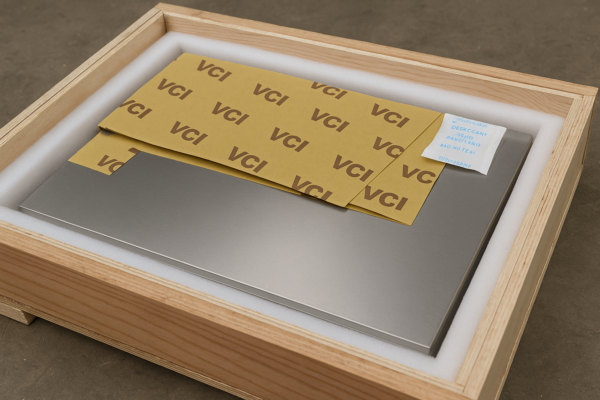

- Use VCI wrap, corner boards, desiccant, and wide straps over pads.

- Separate BA/No.4 faces with interleaf2 to prevent print-through.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Material/Grade | 304 | 316 (Mo-bearing)1 | 316 costs more; better pitting/crevice resistance in chloride splash, lowering life-cycle risk. ([nickelinstitute.org][5]) |

| Finish | 2B | BA / No.4 | BA looks premium; No.4 hides scuffs; both change cleaning frequency. |

| Thickness | 1.0–1.5 mm | 2.0–3.0 mm | Thicker dents less; adds material and bending tonnage. |

| Flatness | Commercial | Laser-flat2 | Tighter flatness improves laser/assembly; costs more. |

| QA | Mill cert | FAI/CMM + CoC | Higher assurance; longer inspection lead. |

Stainless Steel Sheet | Cut To Size | Metal Supermarkets?

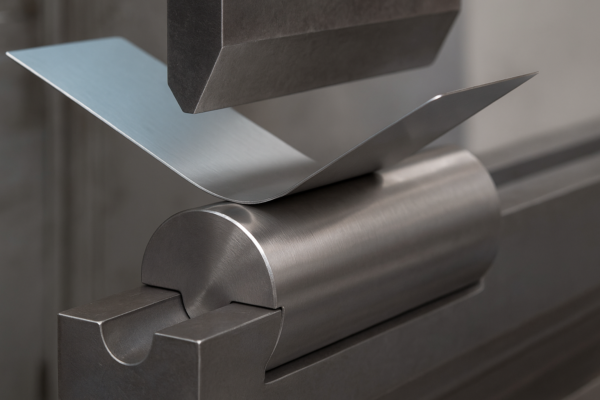

Cut-to-size is convenient—unless edge quality1 and cleanup are undefined. Lock down cut method, burr, and post-cut finishing.

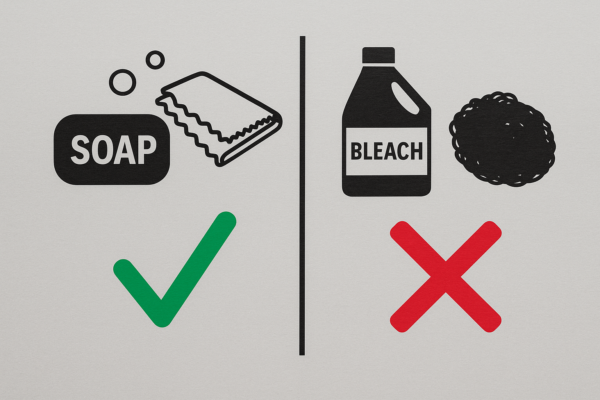

For cut-to-size 304 sheets1, define the cut method (shear/laser/waterjet), size tolerance, burr height, and protective film. After thermal cutting, remove heat tint/oxide and passivate per ASTM A967/A3802 to restore corrosion resistance. Clean with neutral detergents; avoid chloride/bleach; rinse and dry.

Dive Deeper

Edge quality, heat tint, and why passivation matters

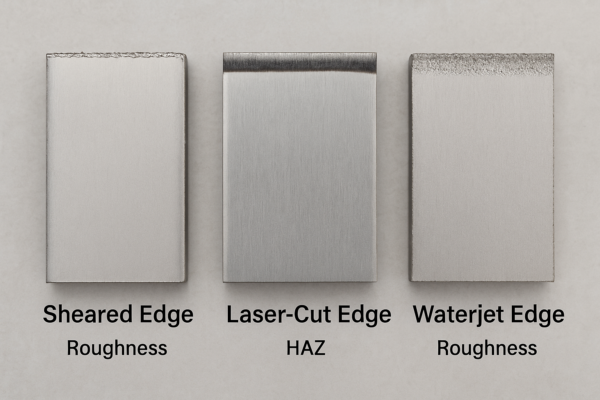

Shearing is fastest and cheapest, but can leave burr and slight bow on thin gauges. Laser delivers narrow kerf and tight tolerance yet creates heat tint and oxide scale—these must be removed because discoloration indicates chromium depletion and locally reduced corrosion resistance. Waterjet avoids heat-affected zones but leaves a matte cut face that may need a light edge break. For visible or hygienic assemblies, I cap burr at ≤0.05 mm (0.002 in) and specify deburr plus passivation after thermal cutting. ASTM A9671 defines chemical passivation methods and acceptance tests; ASTM A3802 gives cleaning/descaling guidance, including heat tint removal.

Cleaning that prevents “rust-like” staining

Daily care is simple and cheap. Use mild, non-chloride detergents1 or specialty stainless cleaners2 plus soft cloths. Rinse with clean water and dry to avoid spots. Avoid bleach, chloride cleaners, and abrasive pads that can pit or scratch 304; if splashed accidentally, rinse immediately and dry. Store sheets flat, clean, and dry; keep dissimilar metals away to avoid contamination.

Prime can route deburr, heat-tint removal1, passivation, FAI/CMM, and export crating2 as line items so you can balance cost versus risk transparently.

Micro-CTA: Send your DXF/STEP—receive DFM notes1, finish samples2, and a quote within 24 hours.

Practical checkpoints buyers should verify

- Cut method chosen for geometry/finish; burr ≤0.05 mm1 on cosmetic parts.

- Thermal cuts: remove heat tint and passivate per ASTM A9672; agree on acceptance test.

Quality & packaging notes buyers care about

- Add edge break/micro-bevel1 for safer handling and better fit.

- Use PVC film2 on A-faces and foam interleaf between blanks.

- Export: VCI + desiccant + heat-shrink over skids; shock/tilt indicators optional.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Cut Method1 | Shear | Laser / Waterjet | Shear is lowest cost; laser/waterjet improve precision and edge quality. |

| Post-cut2 | Deburr only | Deburr + passivate | Passivation adds hours but reduces edge-initiated corrosion risk in service. |

Stainless Steel Sheet | .018"–.030" Thick | K\&S Precision Metals | USA Made – ksmetals?

Thin gauges1 form easily but deform and scratch fast. Tooling, radii, and packaging2 make or break cost and appearance.

For .018–.030 in (0.46–0.76 mm) 304 sheet, use polished/soft tooling1 and inside radii ≥1×t to limit print-through and micro-cracking. Reduce laser heat input on thin stock. After aggressive forming or thermal cutting, clean and passivate per ASTM A967/A3802. In chloride splash, consider 316; otherwise, clean, rinse, and dry.

Dive Deeper

Forming thin sheet without cosmetic damage

Thin 304 is forgiving on tonnage but unforgiving on finish. I orient bends with the rolling direction where possible, choose wide die openings, and keep inside radius at least the material thickness. Polished dies and generous shoulder radii prevent “read-through” on BA/No.4 faces. For laser cutting, lower power and increase assist gas to minimize heat tint and distortion; for waterjet, select a higher pierce quality to avoid edge fray. After forming/cutting, remove visible heat tint and passivate—chemical treatments to ASTM A9671 restore a chromium-rich passive layer; ASTM A3802 offers cleaning/descaling practice. The goal is consistent, corrosion-resistant edges that survive real cleaning routines.

Service environments, finishes, and storage that keep parts looking new

Chloride exposure1 (road salt, sea spray, some detergents) raises pitting risk on 304—worse with heat and stagnant moisture. 316’s molybdenum improves resistance2 if you cannot avoid splash. For visible parts, 2B is a low-gloss workhorse; BA reads premium but shows fingerprints; No.4 hides small scuffs but requires more frequent cleaning. Store thin sheets flat on clean MDF with interleaf; never place them bare on steel racks. Strap bundles over wide pads and add corner protectors. For export, crate in timber with foam panels and sealed VCI plus desiccant so the first part is usable without rework.

Prime (global export to North America, Europe, Middle East, Australia) ships logo-customized parts with DFM advice1, FAI/CMM, and robust packaging, so custom metal parts2 cost stays predictable across batches.

Micro-CTA: Working with .018–.030 in stainless1? Share your drawing—I’ll send bend radii2, edge specs, and a quote within 24 hours.

Practical checkpoints buyers should verify

- Inside radius ≥1×t, polished tooling1, and documented grain direction for cosmetic bends.

- Protective film remains through forming and shipping.

Quality & packaging notes buyers care about

- Inspect coils/sheets for surface lines1 before cutting to avoid systemic defects.

- Stack with foam/paper interleaf; use wide straps and corner boards.

- Export: VCI + desiccant + heat-shrink2 over skids; add shock/tilt indicators for long routes.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Gauge | .018" (0.46 mm) | .030" (0.76 mm)1 | Thicker dents less; higher material cost may reduce scrap in forming. |

| Finish | 2B | BA / No.4 | BA looks premium; No.4 masks scuffs; each affects cleaning cycles. |

| Edge | As-cut | Deburr + micro-bevel | Safer handling and better fit; small added cycle time. |

| Corrosion Plan | Clean/rinse | Upgrade to 3162 | 316 improves chloride resistance; higher raw-material cost. |

Conclusion

Specify ASTM A240 grade/finish, control cutting and A967/A380 passivation, and maintain with neutral cleaning, rinse, and drying—then send drawings for a 24-hour DFM quote.

-

Explore how a thicker gauge can enhance durability and reduce scrap, impacting overall production efficiency. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the superior corrosion resistance of 316 stainless steel, crucial for long-lasting applications. ([nickelinstitute.org][5]) |

| Post-process | None | Passivation (A967/A380) | Restores passive film after cutting/forming; controlled, documented step. ([ASTM International | ASTM][1]) |

| Inspection | Visual | FAI/CMM + CoC | Assures fit in assemblies; adds inspection lead time. | ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

3 Responses

Thank you I have just been searching for information approximately this topic for a while and yours is the best I have found out so far However what in regards to the bottom line Are you certain concerning the supply

Thank you for your kind words! I’m glad you found the information helpful.

As for the bottom line — yes, the information is based on reliable sources and industry experience. However, if you have any specific concerns or need clarification on a particular point, I’d be happy to look into it further for you.

Your writing is like a breath of fresh air in the often stale world of online content. Your unique perspective and engaging style set you apart from the crowd. Thank you for sharing your talents with us.