What Form of Fasteners Is the Most Commonly Used?

Confused by all the fastener options on the market?

The most commonly used fasteners are bolts and screws—valued for their versatility, strength, and ease of assembly across industries.

Let’s break down the most used fasteners and where each performs best.

LOOP_START

What is the most commonly used fastener?

Too many choices can lead to the wrong selection for your application.

Screws are the most commonly used fasteners worldwide, followed closely by bolts, especially in automotive, electronics, and furniture assembly.

Why Screws Lead the Pack

| Fastener Type | Common Use | Key Benefits |

|---|---|---|

| Screws | Consumer goods, electronics | Easy installation, low cost |

| Bolts + Nuts | Machinery, vehicles | High strength, removable |

| Rivets | Aerospace, sheet metal | Permanent, vibration-resistant |

| Nails | Woodworking, framing | Fast, non-precision |

Screws come in hundreds of head types, threads, and coatings. They’re easy to mass-produce and cost-effective. But when strength matters, bolts are better.

At Prime, we supply for both lightweight assemblies and industrial-grade builds. Whether you need 1,000 M3 screws or custom M16 bolts, we’ve got you covered.

LOOP_END

What is the strongest type of fastener?

Not all fasteners are built for extreme force.

The strongest type of fastener is the Grade 8 hex bolt (or ISO Class 12.9 equivalent), made from heat-treated alloy steel with high tensile strength.

Top Fasteners by Strength

| Fastener | Max Tensile Strength | Use Case |

|---|---|---|

| Grade 8 Bolt | ~150,000 psi | Heavy equipment, chassis |

| 12.9 Metric Bolt | ~176,000 psi | Aerospace, robotics |

| Titanium Bolt | ~138,000 psi | Aircraft, high-end racing |

| NAS Bolt (Aerospace) | 180,000+ psi | Aircraft structures |

We use these fasteners regularly in our projects, where clients in aerospace and defense demand top-tier strength and documented quality.

LOOP_END

What are the most common metal fasteners used in construction?

Construction requires specific fasteners to handle loads, weather, and safety codes.

The most common metal fasteners in construction are anchor bolts, lag bolts, carriage bolts, and concrete screws—chosen for strength and material compatibility.

Construction Fasteners Breakdown

| Fastener Type | Construction Use |

|---|---|

| Anchor Bolts | Securing structural columns to concrete |

| Lag Bolts | Heavy wood-to-metal connections |

| Carriage Bolts | Framing, decking |

| Concrete Screws | Attaching fixtures to masonry |

Zinc-plated and galvanized coatings are common to fight rust. At Prime, we manufacture and export and fastening sets for global builders who need certified performance with fast lead times.

LOOP_END

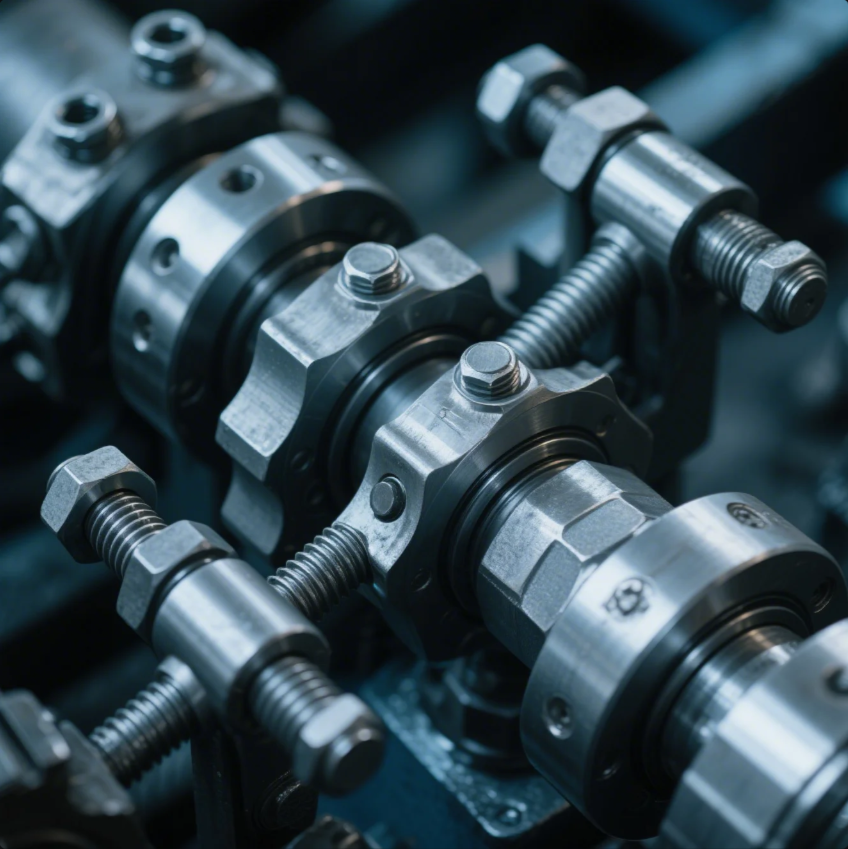

Which type of fastener is best used when you want the strongest mechanical fastening?

When ultimate joint strength is your priority, choosing the wrong fastener can cause catastrophic failure.

For the strongest mechanical fastening, use high-tensile bolts with locking nuts, washers, and proper torqueing—such as Grade 8 or Class 12.9 bolts.

Full-Strength Fastening Strategy

| Component | Role in Joint Strength |

|---|---|

| High-Grade Bolt | Withstands tension and shear |

| Lock Nut | Prevents loosening from vibration |

| Flat Washer | Distributes clamping force |

| Proper Torque | Ensures preload and thread engagement |

Fastener strength isn’t just about the bolt—it’s about the whole fastening system. We provide custom kits and engineering support at Prime to help B2B buyers build reliable, high-load assemblies.

LOOP_END

Conclusion

Screws are the most commonly used fasteners, but high-tensile bolts are your go-to for strength-critical applications.

Need the right fastener for your next project? Contact Prime today. We supply and custom fastening solutions for industrial, construction, and OEM buyers—shipped fast, precision-checked, and built to last.