What is 316 welding rod used for?

Need corrosion resistance in harsh, industrial settings?

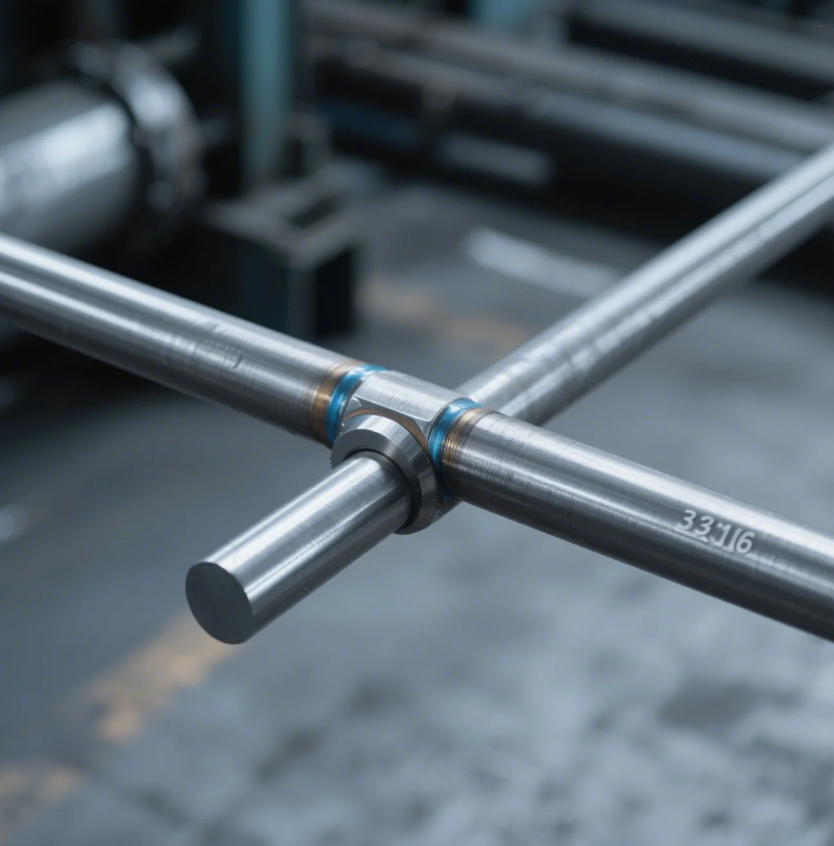

The 316 welding rod is used to weld 316 and 316L stainless steel—especially where resistance to chemicals, saltwater, or high temperatures is critical.

Here’s how it compares to other stainless rods, and when to choose it.

What is the difference between 308 and 316 welding rod?

They both weld stainless—but not for the same jobs.

308 welding rods are used for 304 stainless, while 316 rods are designed for 316/316L stainless, with added molybdenum for superior corrosion resistance.

A Prime client in the marine sector learned this the hard way—using 308 on 316 steel led to early corrosion failures. We switched them to E316L, and their welds held up perfectly in seawater environments.

308 vs. 316 Stainless Rods

| Feature | E308 | E316 |

|---|---|---|

| Intended Base Metal | 304, 302, 321 stainless | 316, 316L stainless |

| Corrosion Resistance | General purpose | Excellent, especially in chlorides |

| Molybdenum Content | None | 2–3% moly added for durability |

| Applications | Food equipment, architecture | Marine, pharma, chemical tanks |

At Prime, we stock both E308 and E316 ISO-certified stainless welding rods, offering guidance to help you match alloy to application.

Is it better to weld 304 or 316 stainless steel?

Both are strong—but 316 stands up to more.

316 stainless is better when corrosion resistance is a priority—especially in saltwater, acidic, or chloride-rich environments.

We once supported a chemical plant in Europe converting from 304 to 316 for tank assemblies. The welds had to hold up against acidic vapor—316 performed better and reduced replacement costs long term.

304 vs. 316 Stainless

| Property | 304 Stainless | 316 Stainless |

|---|---|---|

| General Strength | High | High |

| Cost | Lower | Higher |

| Corrosion Resistance | Moderate | Excellent (chloride-rich) |

| Welding Rod Match | E308 or E308L | E316 or E316L |

Prime offers custom stainless welding kits for 304 or 316 welding, depending on your needs—backed by expert alloy matching and traceability.

What is a 304 welding rod used for?

It’s for the most common stainless in fabrication.

E308 and E308L welding rods are used to weld 304 stainless steel—ideal for food processing, tanks, piping, and commercial kitchens.

A client in the U.S. used our E308L rods to fabricate custom brewing equipment. The welds passed all food-grade tests and held up through repeated sterilizations.

304 Stainless Applications

- Dairy and food equipment

- Brewing tanks

- Commercial kitchens

- Non-marine piping and tubing

| Rod Type | Best For | Notes |

|---|---|---|

| E308 | 304/302/301 stainless | Standard applications |

| E308L | 304L (low carbon) | Prevents carbide precipitation |

Prime supplies both rod types in our food-grade certified welding assemblies, ensuring smooth bead finish and strong corrosion resistance.

What is the electrode E316 used for?

It’s the go-to for critical corrosion zones.

E316 electrodes are used to weld 316/316L stainless steel, especially in chemical processing, marine, and pharmaceutical environments.

One of our Middle Eastern clients relied on E316 for heat exchanger repairs exposed to seawater. We supplied vacuum-packed rods with full material certificates, and their system passed inspection with zero corrosion after six months.

Key Features of E316 Rods

| Property | Value |

|---|---|

| Alloy Base | 316/316L stainless |

| Filler Composition | 19% Cr, 12% Ni, 2–3% Mo |

| Corrosion Resistance | Outstanding in chlorides, acids |

| Application | Marine, chemical, pharmaceutical |

| Weld Appearance | Smooth bead, minimal slag |

For every Prime-supplied stainless steel welding project, we help select between E316 and E308 rods based on job conditions and inspection requirements.

Conclusion

E316 rods are ideal for welding 316 stainless steel in corrosive, marine, or chemical environments—durable, strong, and clean.

Need help choosing the right stainless steel electrode? Contact Prime now through our website for expert consultation, ISO-certified welding rods, and fast global delivery—trusted by professionals worldwide.