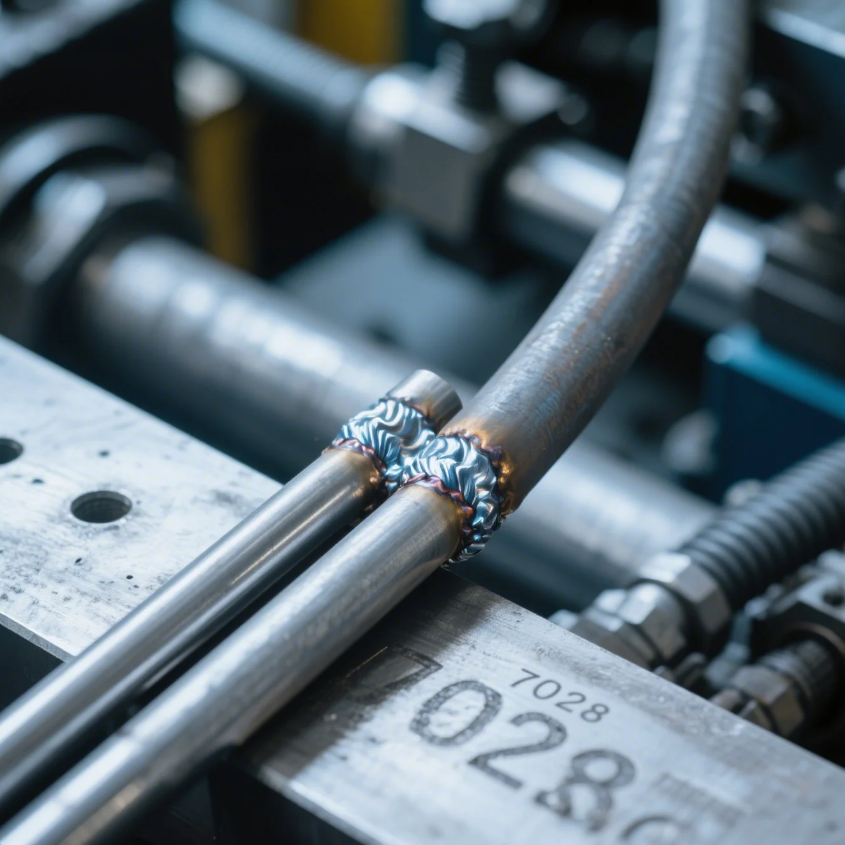

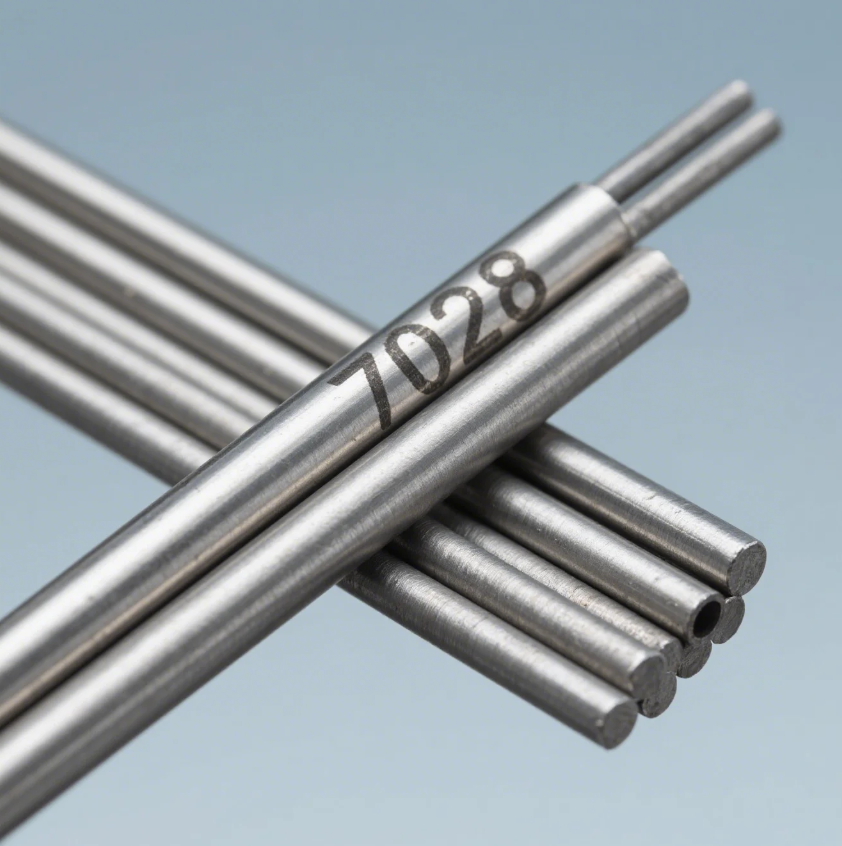

What is a 7028 welding rod used for?

Need speed and strength for flat welding?

The 7028 welding rod is used for high-deposition, flat-position welding on heavy steel—ideal for structural work, manufacturing, and thick plate fabrication.

Let’s compare 7028 with similar rods, and see where it performs best.

What is 7028 welding rod used for?

It’s all about speed, strength, and volume—in flat positions only.

7028 rods are used in high-production settings for welding thick, clean steel in flat or horizontal positions, offering fast deposition and low spatter.

One of our industrial clients in North America used 7028s to weld massive base plates for machine foundations. With just two passes, they achieved fusion where it would take four using standard rods.

Key uses for 7028 rods

- Heavy-duty fabrication

- Weldments requiring thick deposits

- Plate and structural steel

- High-strength, low-hydrogen joints

| Feature | 7028 Performance |

|---|---|

| Deposition Rate | Very high |

| Penetration | Moderate |

| Position | Flat and horizontal only |

| Coating | Iron powder, low hydrogen |

| Power Source | AC or DC+ compatible |

At Prime, we supply 7028 rods for clients handling ISO-certified heavy welding projects, where time and strength are equally critical.

What is a 7018 welding rod good for?

It’s the all-around champ for structural strength.

7018 rods are ideal for low-hydrogen, high-strength welds on clean steel, especially in structural, pressure vessel, and code-required applications.

A Prime client in the Middle East used 7018 for pipe supports on an offshore platform—where weld failure isn’t an option. Every rod was vacuum-sealed and delivered with certification data.

7018 welding rod benefits

- Excellent tensile strength (≥70,000 psi)

- Smooth arc and clean weld appearance

- Low hydrogen = less cracking risk

- Works in all positions (flat, vertical, overhead)

| Application | Why Use 7018 |

|---|---|

| Buildings & bridges | Strong welds, code compliance |

| Boilers and tanks | Resistant to hydrogen-induced cracks |

| Truck & trailer frames | Reliable in vibration-heavy uses |

| Machinery structures | Clean bead, minimal cleanup |

Prime offers full traceability for 7018s in industrial welding part kits, making them trusted worldwide for critical welds.

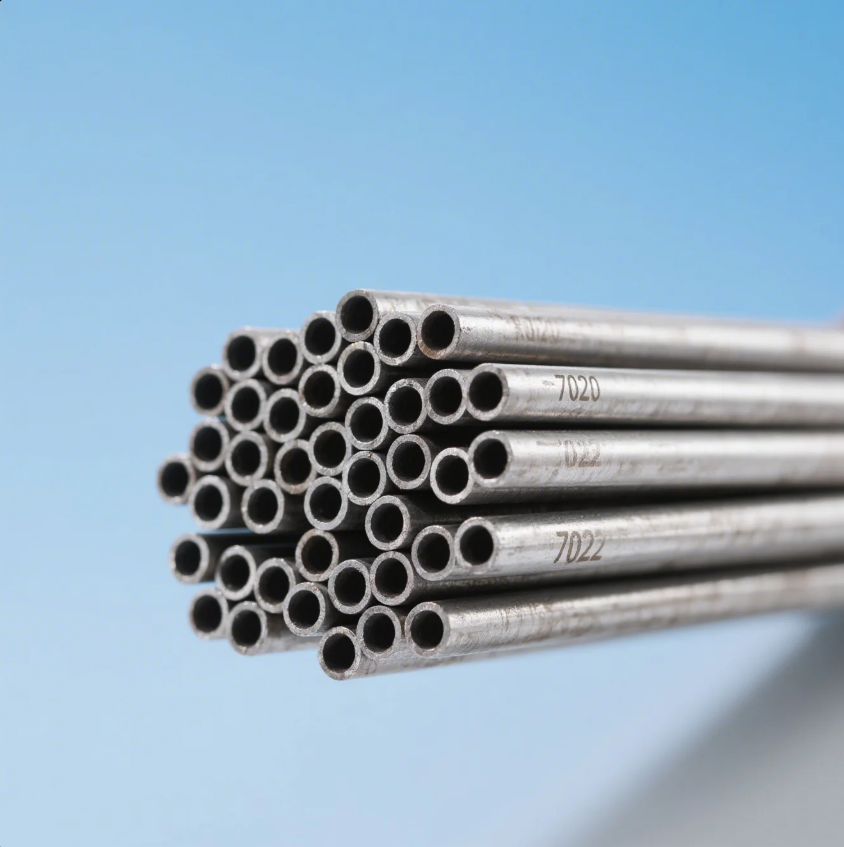

What is a 7024 welding rod good for?

It’s made for fast, flat fillets.

7024 welding rods are used for flat or horizontal welding on mild steel where high-speed, smooth, and clean fillet welds are needed.

One client in Eastern Europe builds trailers and needed a rod for fast floor welds with minimal spatter. We supplied 7024s—and they cut labor time in half.

7024 rod features

- Fast fill for fillet and lap welds

- Flat-position only

- Extremely smooth arc

- Very low spatter

- AC or DC power

| Rod Type | Best Use Case | Notes |

|---|---|---|

| 7024 | Flat fillet welds, angle iron, frame rails | Not suitable for vertical welds |

At Prime, we recommend 7024 for clients producing custom frames, gates, and industrial bases, where bead aesthetics and speed are critical.

What is the hardest welding rod to use?

The most advanced rod demands advanced skill.

E6010 is often considered the hardest welding rod to use due to its fast-freeze puddle, arc blow tendency, and strict angle control.

We once worked with a U.S. contractor on a high-pressure pipe system. They insisted on 6010 for root passes. Only certified welders passed inspection—because even small errors led to root gaps or lack of fusion.

Why E6010 is difficult

- Thin arc with fast-freeze puddle

- Needs whip-and-pause motion

- Prone to arc blow and spatter

- No flux to mask mistakes

| Rod Type | Skill Required | Ideal Use |

|---|---|---|

| E6010 | High | Pipe roots, vertical welding |

| E7018 | Moderate | Structural work, clean steel |

| E7028 | Low to moderate | Flat, heavy welds |

Prime supplies training-ready welding rod kits for clients looking to upskill teams on challenging rods like 6010—while also recommending 7028s for flat work where productivity matters.

Conclusion

7028 is the rod of choice for flat-position, high-volume welds on heavy steel—strong, clean, and fast.

Need help selecting the right rod for high-efficiency fabrication? Contact Prime today through our website. Get free expert support, ISO-certified consumables, and fast global delivery to keep your welding projects on track.