What is a Caterpillar Weld?

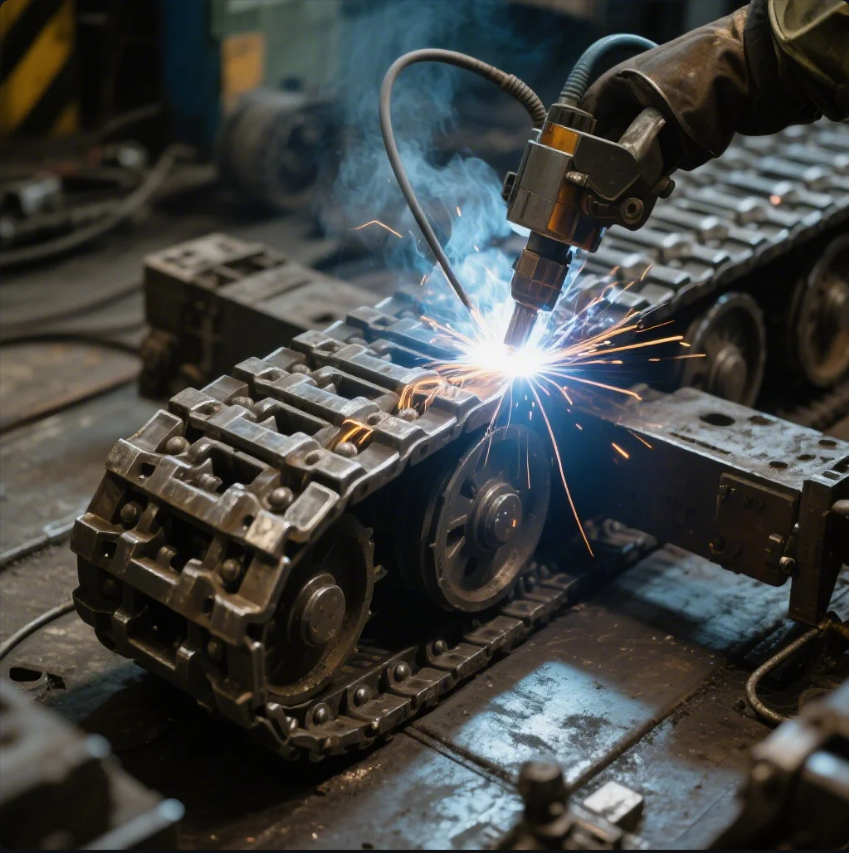

Caterpillar welds are not a specific type of welding process, but the term is often used in reference to the welding techniques used in Caterpillar machinery and equipment. Caterpillar Inc., a leading manufacturer of heavy machinery, uses various welding methods to build and repair their equipment. Understanding the types of welding processes involved in their operations can provide insight into how strong and reliable their machines are. Let’s take a closer look at the term "Caterpillar weld" and the welding methods commonly used in the industry.

Snippet paragraph: Caterpillar welds are associated with the welding techniques used in manufacturing and repairing heavy equipment, ensuring strong, durable bonds for high-stress applications.

Transition paragraph: Now, let’s explore the types of welding Caterpillar uses, what "cat weld" means, and how these techniques compare to other welding methods.

What type of welding does a Caterpillar do?

Caterpillar Inc. employs several types of welding processes in the manufacturing and repair of their heavy machinery, including MIG welding, TIG welding, stick welding (SMAW), and flux-cored arc welding (FCAW). These welding methods are chosen based on the material being welded, the strength required, and the specific application.

Common Welding Methods at Caterpillar

- MIG Welding (GMAW): Used for its speed and efficiency, MIG welding is commonly used in production lines for welding thinner materials.

- TIG Welding (GTAW): Provides precise and clean welds, especially for delicate components or high-strength materials like stainless steel.

- Stick Welding (SMAW): A more robust process that is ideal for outdoor or heavy-duty applications, often used in the repair and maintenance of machinery.

- Flux-Cored Arc Welding (FCAW): Similar to MIG welding but uses a flux-cored wire, making it ideal for thicker materials or outdoor work where shielding gas might be affected by the wind.

| Welding Type | Common Use in Caterpillar | Features |

|---|---|---|

| MIG Welding | Production of lighter components | Fast, clean, and efficient |

| TIG Welding | Precision welding of critical parts | High-quality, clean welds |

| Stick Welding | Heavy-duty repairs and outdoor work | Strong welds, versatile |

| FCAW | Thicker materials, outdoor work | Good for tough conditions |

These methods ensure that Caterpillar equipment remains strong and durable, even under extreme conditions.

What is a Cat Weld?

A "Cat weld" refers to the welding processes and standards used by Caterpillar Inc. in their machinery and equipment. These welding methods are critical to the integrity and reliability of the machines that Caterpillar manufactures, as their products are built to withstand harsh conditions in industries like construction, mining, and agriculture.

Caterpillar Welding Standards

Caterpillar follows strict industry standards when it comes to welding, ensuring that their machines can perform under extreme conditions. These standards cover everything from the types of welding techniques used to the materials and equipment involved. Cat welds are often characterized by their high strength and durability, which is crucial for the heavy-duty applications Caterpillar machines are used for.

| Cat Weld Feature | Description |

|---|---|

| Strength | Designed to handle heavy loads and stress. |

| Precision | High-quality welds for long-lasting durability. |

| Durability | Welds withstand harsh environmental conditions. |

A Cat weld essentially guarantees a high-quality, reliable joint that can hold up to the demands of construction and mining.

What is the Caterpillar Symbol in Welding?

The Caterpillar symbol in welding is often associated with the Caterpillar Inc. logo—a distinct yellow and black triangle with a "CAT" logo in the middle. This symbol can sometimes be seen on welding equipment or products related to Caterpillar machines.

However, in terms of welding, the Caterpillar symbol may also refer to the standards and quality of welds that are characteristic of Caterpillar machinery. These welds are designed to ensure durability, safety, and performance under tough conditions.

Significance of the Caterpillar Symbol in Welding

The Caterpillar symbol is more than just a brand logo; it represents the rigorous quality standards that the company follows in its manufacturing processes. A Caterpillar weld is a seal of approval for a high-quality, reliable product that can withstand challenging environments and heavy workloads.

| Symbol | Significance |

|---|---|

| CAT Logo | Represents the high standards in equipment and welding quality. |

| Weld Quality | Welds with the CAT symbol are designed for durability and strength. |

The Caterpillar symbol serves as a mark of excellence, ensuring that the welds meet the company’s stringent quality controls.

What are the Four Types of Welds?

When discussing welding in general, it’s important to understand the four basic types of welds used in the industry. These welds are commonly applied across various welding methods, including those used by Caterpillar in the manufacturing of heavy machinery.

The Four Main Types of Welds:

- Butt Weld: A weld that joins two pieces of metal end-to-end. Common in pipe welding and structural applications.

- Fillet Weld: A triangular weld used to join two surfaces at a right angle, often used in construction and heavy equipment.

- Edge Weld: This type of weld is used to join the edges of two pieces of metal, commonly used in the automotive and aerospace industries.

- Tee Weld: Used to join a piece of metal to the center of another, creating a “T” shape. Common in structural steel applications.

| Weld Type | Description | Common Use |

|---|---|---|

| Butt Weld | Joins two pieces end-to-end. | Pipe welding, structural work. |

| Fillet Weld | Joins two pieces at a right angle. | Construction, heavy equipment. |

| Edge Weld | Joins the edges of two pieces. | Automotive, aerospace. |

| Tee Weld | Joins the center of one piece to another. | Structural steel, metal framing. |

Caterpillar machinery often uses fillet welds and tee welds, as these types of welds are ideal for joining thick materials and ensuring structural integrity.

Conclusion

A Caterpillar weld refers to the robust and durable welding methods used by Caterpillar Inc. in their manufacturing processes. These welds are essential for the strength and longevity of heavy equipment like bulldozers, excavators, and mining machines. Whether it’s MIG, TIG, or stick welding, each method is carefully selected for the task at hand to ensure that the machinery can withstand the toughest environments.

If you’re in need of high-quality welding solutions for heavy machinery or industrial applications, Prime is here to help. Contact us today for fast delivery, expert advice, and top-notch products tailored to your needs.