What Is a CNC Part Program?

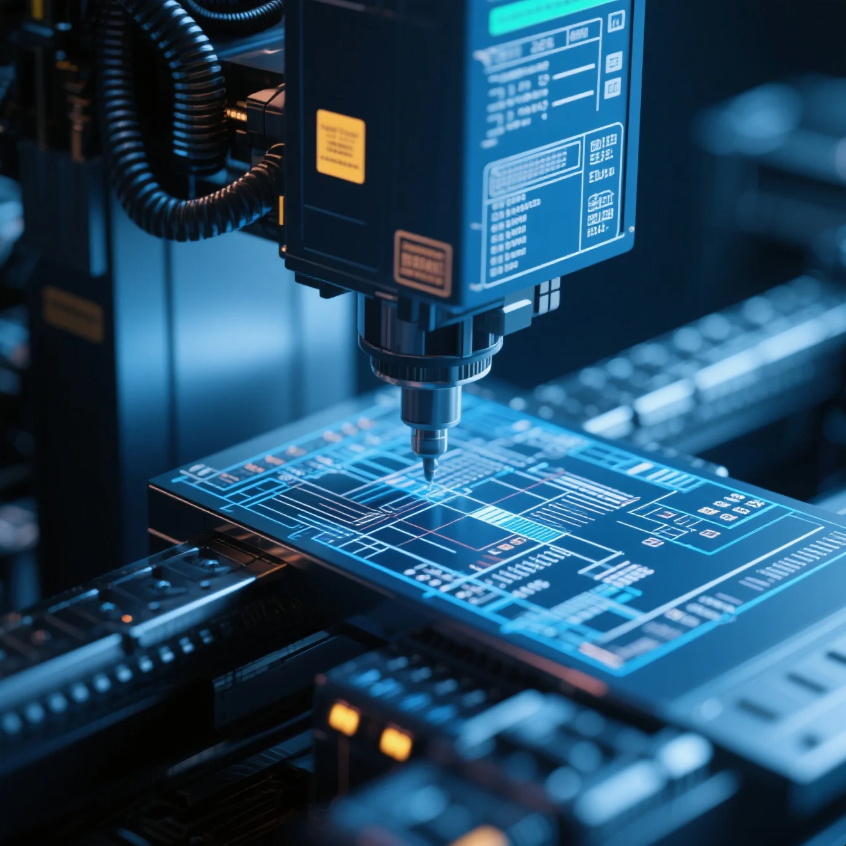

Leading paragraph: A CNC part program is essential for controlling the precise movement of machines to create intricate and high-quality parts. Understanding how it works is key to mastering CNC machining.

Snippet paragraph: CNC part programming is a process in which coded instructions are written for CNC machines to produce specific parts. This allows for high precision in manufacturing motor parts and other components.

Transition paragraph: Let’s break down what a CNC program is, how it works, and what steps are involved in creating one. Understanding these elements can help you achieve better manufacturing results.

What Is a CNC Program?

Leading paragraph: A CNC program is a set of coded instructions written to control the movement of CNC machines. These instructions are necessary to create specific parts with high precision.

Snippet paragraph: A CNC program consists of commands in a special programming language that direct the machine’s tools to move in specific ways. These commands can control speed, direction, and positioning.

Dive-Deeper paragraph: CNC programs are written in a language known as G-code, which instructs the machine on how to move its tools. The program includes information about the speed, feed rate, tool path, and other variables necessary to produce the desired part. CNC programs can vary depending on the machine type and the complexity of the part being manufactured. The main purpose of a CNC program is to automate the machining process, ensuring consistency and precision in the production of parts.

G-Code and M-Code

The two most common types of code in CNC programming are G-code (Geometric Code) and M-code (Miscellaneous Code). G-code commands control the machine’s movement, while M-code controls auxiliary functions like turning on or off the spindle.

What Does CNC Mean in College?

Leading paragraph: In college, CNC typically refers to the study of Computer Numerical Control systems and how they are used in manufacturing and engineering fields. Students learn how to operate CNC machines and understand their programming.

Snippet paragraph: CNC in college refers to programs that teach students about CNC machinery and how to write programs for them. This knowledge is essential for careers in manufacturing, engineering, and automation.

Dive-Deeper paragraph: CNC programs in college are often part of engineering, manufacturing, or technical disciplines. These programs teach students how to use CNC machines, program them, and troubleshoot issues. Students also learn to write CNC programs using G-code and understand the fundamentals of automation and precision machining. Knowledge of CNC programming is highly valuable in fields like automotive manufacturing, aerospace, and industrial engineering, where precision and efficiency are critical.

CNC Training and Certification

Many colleges offer specialized CNC courses, and there are also certifications available for students to prove their proficiency in CNC operations. These certifications can help students stand out in the job market and secure positions in manufacturing or machine operation.

What Are the Steps Involved in CNC Part Programming?

Leading paragraph: CNC part programming involves several key steps to ensure that the machine produces the desired component accurately and efficiently. Here are the key stages of programming.

Snippet paragraph: CNC part programming involves steps such as designing the part, selecting the tools, and writing the program in G-code. Each step is essential to ensure precision and successful machining.

Dive-Deeper paragraph: The steps involved in CNC part programming typically include the following:

- Designing the Part – The first step is to create a detailed design of the part using CAD (Computer-Aided Design) software. This design includes the exact dimensions and specifications required for the part.

- Choosing Tools – Once the design is finalized, the next step is selecting the tools that will be used for the machining process. These tools include end mills, drills, and lathes, among others.

- Writing the CNC Program – Using the design and tool selections, the CNC programmer writes the program using G-code, specifying tool paths, speeds, and feed rates.

- Simulation – Before the actual machining begins, the program is tested in a virtual environment to check for any errors or issues that could occur during the physical process.

- Running the Program – Once the program is verified, the CNC machine is set up with the selected tools, and the part is machined according to the instructions in the program.

- Post-Processing – After the part is produced, any finishing touches or secondary operations are completed, such as polishing or deburring.

Importance of Precision in CNC Programming

Each step in CNC part programming is critical to ensuring that the final product meets exact specifications. Precision is key in CNC machining, as even small errors in programming can lead to defective parts.

What Is a CNC Programmer’s Salary?

Leading paragraph: CNC programmers play an important role in the manufacturing industry, ensuring machines produce parts with high accuracy. Let’s explore how much a CNC programmer typically earns.

Snippet paragraph: CNC programmers earn competitive salaries, with the average salary varying depending on experience, location, and industry. On average, CNC programmers in the U.S. earn between \$50,000 and \$70,000 per year.

Dive-Deeper paragraph: The salary of a CNC programmer can vary based on factors such as experience, geographical location, and the specific industry. In the United States, the average salary for a CNC programmer is around \$60,000 per year, but this can range from \$50,000 to over \$70,000 depending on expertise and demand in specific areas. Experienced programmers with specialized skills in high-precision industries like aerospace or automotive manufacturing may command higher salaries. In addition, CNC programmers can increase their earning potential by acquiring certifications and continuing their education in advanced CNC technologies.

Factors That Affect CNC Programmer Salaries

- Experience Level: Entry-level programmers tend to earn less, while those with more experience can earn significantly more.

- Industry: CNC programmers working in industries such as aerospace or medical device manufacturing may earn higher salaries than those working in less specialized sectors.

- Location: Salaries can vary by region, with higher wages often found in areas with a higher cost of living or in industries that are in high demand for CNC programming.

Conclusion

CNC part programming is an essential skill in the modern manufacturing process, offering precision and efficiency in creating high-quality parts. Whether you’re a student learning CNC programming in college or a professional programmer, understanding the steps involved and the importance of precision is key. If you need high-quality CNC parts for your business, Prime can help. Reach out to us today for a quote and tailored solutions to meet your machining needs.