What Is a High Strength Fastener?

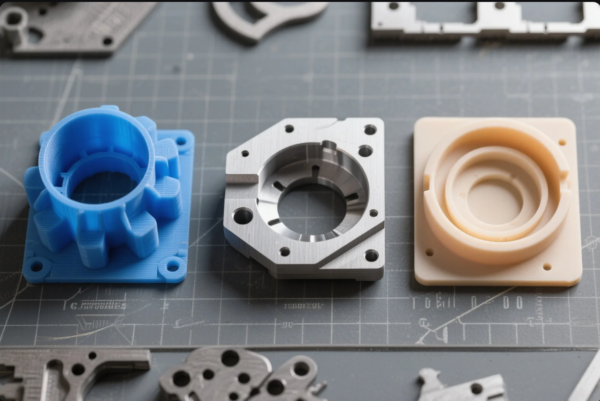

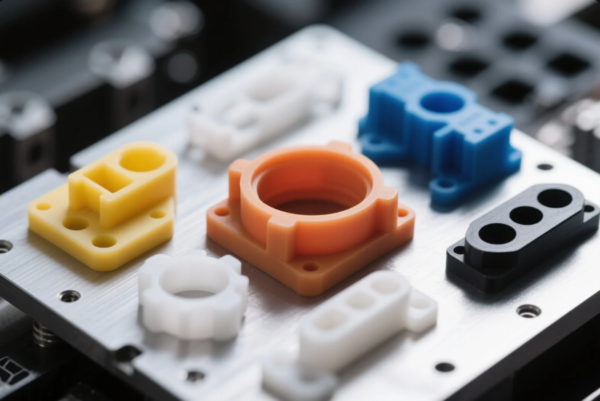

Leading paragraph: High-strength fasteners are designed to withstand higher loads and stresses than standard fasteners. These fasteners are essential in applications where safety and durability are critical.

Snippet paragraph: High-strength fasteners, such as bolts and screws, are made from materials that offer enhanced strength and performance under extreme conditions. They are ideal for heavy-duty applications in construction, automotive, and industrial machinery.

Transition paragraph: Let's dive into what makes a fastener "high strength," the types of fasteners that fall into this category, and the differences between them and standard fasteners.

What Is Considered a High Strength Bolt?

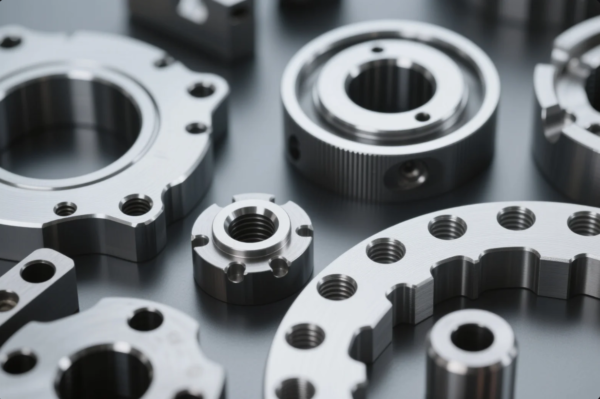

Leading paragraph: A high-strength bolt is a bolt that is specifically designed to handle higher loads and stresses than a standard bolt. These bolts are made from stronger materials and are often used in critical applications.

Snippet paragraph: High-strength bolts are made from materials like alloy steel, and they are heat-treated to provide greater strength and resistance to fatigue and wear. These bolts are commonly used in structural and heavy-duty applications.

Dive-Deeper paragraph: High-strength bolts are typically made from high-quality materials, such as carbon steel or alloy steel, and are heat-treated to increase their tensile strength and resistance to wear. These bolts can handle significantly more stress than regular bolts, making them ideal for construction, automotive, and heavy machinery applications. High-strength bolts are rated based on their material properties and are often used in situations where structural integrity is critical.

Key Features of High Strength Bolts

- Material: Made from high-carbon steel or alloy steel.

- Heat Treatment: Often heat-treated to increase their strength and fatigue resistance.

- Tensile Strength: High-strength bolts have much higher tensile strength compared to regular bolts, typically in the range of 120-150 ksi (kilo pounds per square inch) or more.

Is A325 a High Strength Bolt?

Leading paragraph: A325 bolts are a common type of high-strength bolt used in construction and industrial applications. But are they considered high strength compared to other bolts? Let’s explore.

Snippet paragraph: Yes, A325 bolts are considered high-strength bolts. They are commonly used in structural applications and are manufactured to meet specific tensile strength requirements.

Dive-Deeper paragraph: The A325 bolt is a standard for high-strength bolts, especially used in structural steel connections. These bolts are made from medium-carbon steel and are heat-treated to achieve a tensile strength of 120-150 ksi, which makes them capable of handling high loads and stresses. A325 bolts are commonly used in bridges, buildings, and other heavy-duty applications where structural integrity is paramount. Their high strength ensures they perform well in demanding conditions, making them a reliable choice for critical applications.

Common Applications of A325 Bolts

- Steel Structures: Used to fasten large steel beams and plates in buildings, bridges, and other infrastructures.

- Heavy Machinery: Commonly used in machinery that operates under heavy loads or stress.

What Is the Difference Between High Strength Bolts and Normal Bolts?

Leading paragraph: The primary difference between high-strength bolts and normal bolts lies in the material composition, heat treatment, and the ability to withstand higher loads and stresses.

Snippet paragraph: High-strength bolts are designed for more demanding applications, offering superior tensile strength, fatigue resistance, and durability compared to standard bolts. They are often heat-treated to improve their performance.

Dive-Deeper paragraph: The differences between high-strength bolts and normal bolts include:

- Material: High-strength bolts are made from stronger, alloyed materials, while standard bolts are often made from lower-grade steel or other materials.

- Heat Treatment: High-strength bolts are often heat-treated to increase their strength, while normal bolts typically are not.

- Tensile Strength: High-strength bolts are rated for higher tensile strength, often exceeding 100 ksi, whereas regular bolts typically range between 60-100 ksi.

- Applications: High-strength bolts are used in critical, heavy-duty applications like structural steel, machinery, and automotive manufacturing, while regular bolts are sufficient for light-duty tasks and general-purpose use.

Choosing Between High Strength and Normal Bolts

- High Strength: Ideal for heavy-duty, load-bearing applications such as construction and automotive manufacturing.

- Normal Bolts: Suitable for lighter tasks like furniture assembly or non-critical applications.

What Is the Strongest Type of Fastener?

Leading paragraph: When it comes to fasteners, strength varies depending on the material, design, and intended use. But which type of fastener is the strongest? Let’s look at the options.

Snippet paragraph: The strongest type of fastener is typically the bolt, especially high-strength variants like A325 or A490 bolts, which are designed to handle extreme loads and stresses in structural applications.

Dive-Deeper paragraph: The strongest type of fastener is typically a high-strength bolt, especially those made from alloy steel or heat-treated materials. Some of the strongest bolts include:

- A490 Bolts: These bolts have a higher tensile strength than A325 bolts, with a tensile strength of 150 ksi. They are often used in critical applications requiring maximum strength, such as in bridges and large steel structures.

- Tension-Control Bolts: These bolts are designed to maintain high tensile strength and are commonly used in high-stress, structural applications.

- Titanium Fasteners: Known for their strength and light weight, titanium fasteners are often used in aerospace and high-performance automotive applications.

Strength Factors in Fasteners

- Material: Steel alloys, titanium, and other high-strength materials contribute to the fastener’s strength.

- Design: The geometry of the fastener, including thread type and length, also influences its strength.

- Heat Treatment: Heat-treated fasteners tend to offer better tensile strength and fatigue resistance than untreated ones.

Conclusion

High-strength fasteners are essential in applications where strength, durability, and safety are crucial. Bolts like A325 and A490, as well as materials like titanium, offer the highest strength for critical applications. If you're looking for strong, reliable fasteners, Prime provides high-quality solutions designed to meet your specific needs. Contact us today for expert advice and tailored fastener solutions for your projects!