What is a metal fastener called?

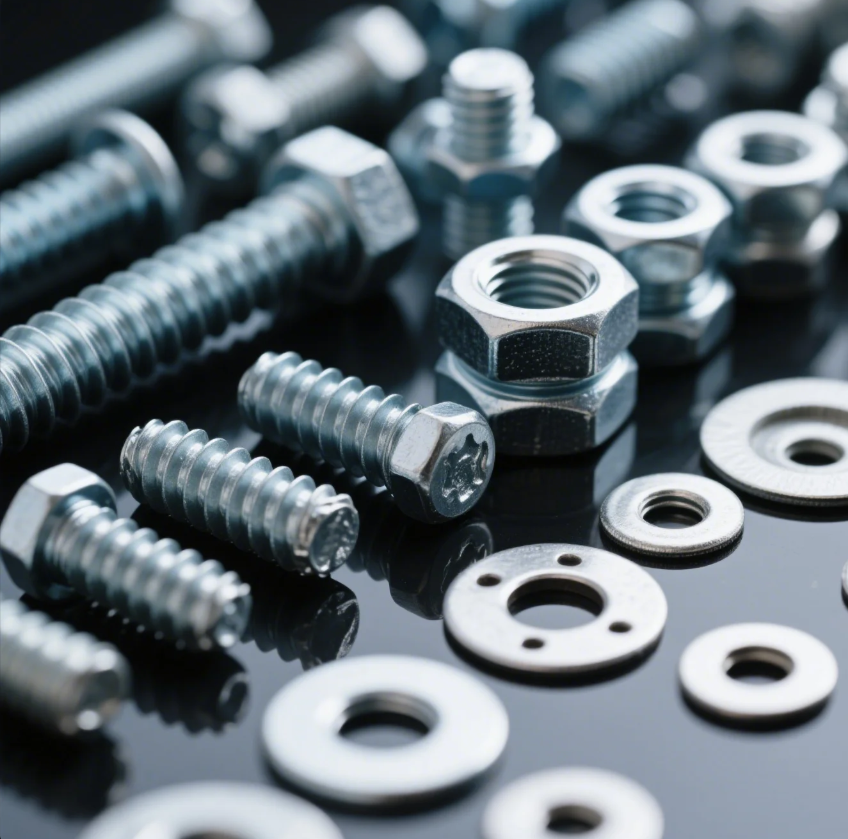

Metal fasteners are essential components used in various applications, from construction to everyday items. In this article, we’ll explore what metal fasteners are called and the different types available.

Snippet paragraph: Metal fasteners play a crucial role in many industries. This article explores what metal fasteners are called and their different forms.

Understanding the terminology of metal fasteners is important for both professionals and hobbyists. Let’s dive into what metal fasteners are commonly called and explore some key types used in different industries.

What is another word for metal fastener?

Another word for a metal fastener is simply fastener or connector. In the context of joining metal parts together, fasteners are devices that hold objects securely in place.

Common Synonyms for Metal Fasteners:

- Fastening Devices: A broad term used for all types of fasteners.

- Clamps: Often used in woodworking, metalworking, and plumbing.

- Connectors: Sometimes used when the primary function is to connect materials securely.

Types of Metal Fasteners:

| Term | Description |

|---|---|

| Fasteners | General term for devices that join materials together |

| Clamps | Used to hold objects securely, often temporarily |

| Connectors | Devices that connect two materials, often in electrical or mechanical applications |

What are 7 types of fasteners?

There are numerous types of fasteners, each suited for different applications. Seven common types of fasteners include:

- Screws: Threaded fasteners used to join materials by turning them into the material.

- Bolts: Used with nuts to secure materials together, often in heavy-duty applications.

- Nuts: Used with bolts to keep them in place, commonly seen in machinery and structural work.

- Rivets: Permanent fasteners used to join materials, typically in metalworking.

- Washers: Used with screws and bolts to distribute pressure and prevent damage to the material.

- Pins: Small cylindrical fasteners used to secure parts in place or align them.

- Clips: Fasteners that apply pressure to hold parts or components in place.

Comparison of Common Fasteners:

| Fastener Type | Description | Common Applications |

|---|---|---|

| Screws | Threaded fasteners for joining materials | Woodworking, construction, automotive |

| Bolts | Large fasteners used with nuts | Machinery, heavy-duty equipment |

| Nuts | Hexagonal fasteners to secure bolts | Industrial machinery |

| Rivets | Permanent fasteners for metalwork | Aerospace, construction, automotive |

| Washers | Distribute load and prevent surface damage | General industrial applications |

| Pins | Cylindrical fasteners to secure components | Engineering, automotive |

| Clips | Apply pressure to secure components | Electrical, automotive, wiring |

These fasteners each have their own unique role and are used in a variety of industries, from construction to manufacturing.

What is a metal fastener called in sewing?

In sewing, a metal fastener is typically referred to as a sewing fastener or more commonly sewing hardware. Specific types of metal fasteners used in sewing include buttons, zippers, snaps, and hooks and eyes.

Common Metal Fasteners in Sewing:

- Buttons: Used to fasten clothing or accessories.

- Zippers: Used in garments, bags, and other items for a secure closure.

- Snaps: Common in jackets, shirts, and accessories, offering a quick closure.

- Hooks and Eyes: Used in garments for a secure and adjustable closure.

Sewing Metal Fasteners Overview:

| Fastener Type | Description | Common Uses |

|---|---|---|

| Buttons | Round or flat fasteners sewn onto fabric | Shirts, pants, coats |

| Zippers | Interlocking teeth used for a secure closure | Jackets, bags, pants |

| Snaps | Two pieces that snap together for a quick closure | Jackets, bags, children’s clothes |

| Hooks and Eyes | Small hooks and loops used for adjustable closures | Dresses, bras, corsets |

These fasteners are essential for providing secure and functional closures in garments and accessories.

What are the four types of fasteners?

The four main types of fasteners are screws, bolts, nuts, and rivets. These fasteners are commonly used across various industries, from construction to manufacturing.

1. Screws

Screws are threaded fasteners used to join materials by rotating them into place. They are used in woodworking, construction, and metalworking.

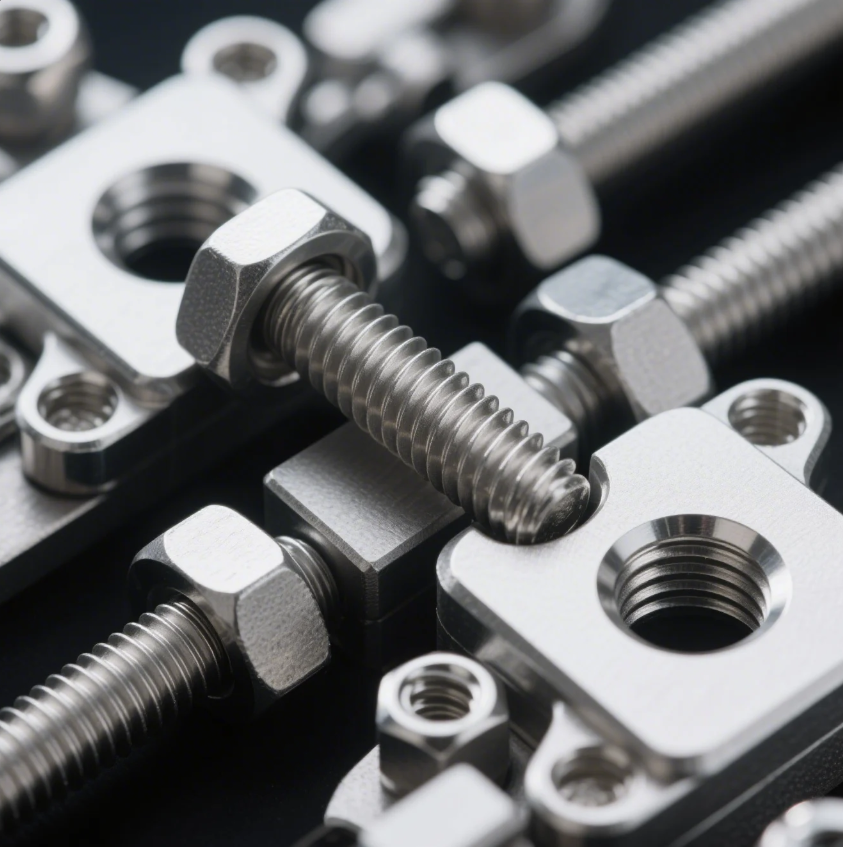

2. Bolts

Bolts are used in conjunction with nuts to secure materials together, often in heavy-duty applications such as machinery and structural work.

3. Nuts

Nuts are hexagonal fasteners used with bolts to keep them secure and hold components in place.

4. Rivets

Rivets are permanent fasteners that are used to join materials together by deforming the rivet after it’s inserted through a hole.

Fastener Types Comparison:

| Fastener Type | Description | Common Uses |

|---|---|---|

| Screws | Threaded fasteners for joining materials | Woodworking, automotive, fabrication |

| Bolts | Used with nuts to fasten materials | Construction, heavy machinery |

| Nuts | Used with bolts to secure materials | Industrial machinery |

| Rivets | Permanent fasteners for metal applications | Aerospace, shipbuilding, automotive |

These four fasteners are the most commonly used in industrial applications and have specific roles in ensuring secure connections.

Conclusion

A metal fastener is a component used to secure or join materials together, and it can be referred to by several names, such as fastener, connector, or clamp. The most common types of metal fasteners include screws, bolts, nuts, and rivets, and they are used in various applications, from construction to sewing. Understanding these fasteners and their uses is essential for choosing the right one for your project.

At Prime, we provide high-quality fasteners and metal components for a wide range of industries. Contact us today for expert advice and customized solutions tailored to your needs!