What is a metal stamping machine?

Stamping machines shape metal fast and precisely. They’re essential for high-volume industrial parts.

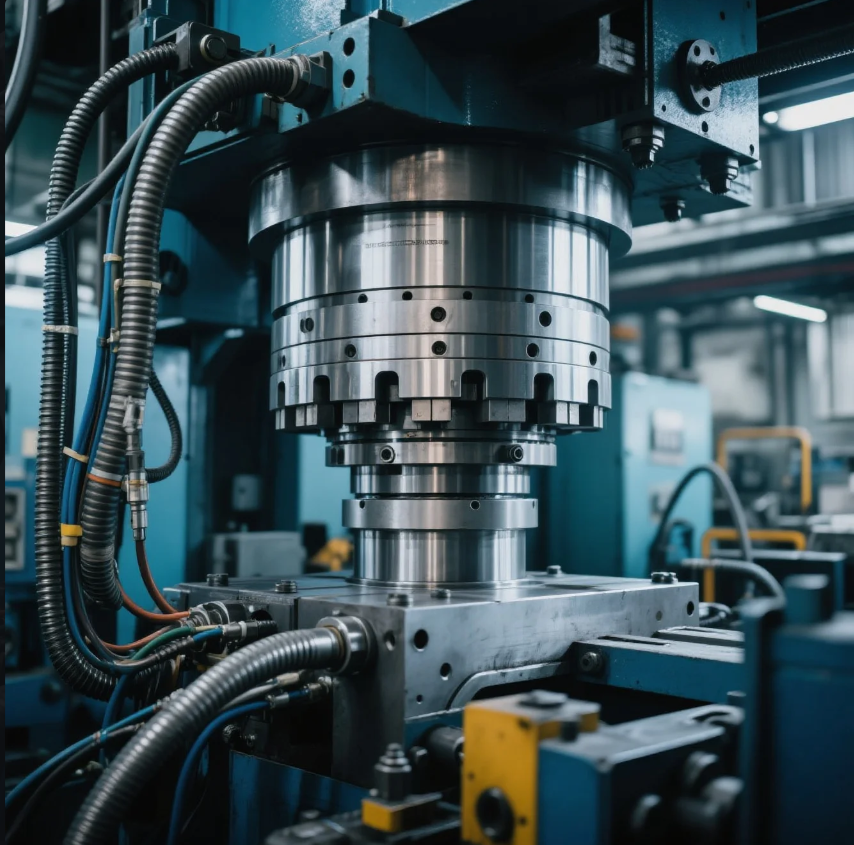

A metal stamping machine presses sheet metal into shapes using a die. It’s widely used in mining, automotive, and machinery parts production.

Using the right stamping method saves time, cost, and boosts part consistency. In this article, I’ll explain how stamping machines work and how Prime uses them to deliver top-quality custom parts.

What does a stamping machine do?

A stamping machine shapes metal using force. It turns flat sheets into precise, strong parts in seconds.

Stamping machines punch, bend, or cut metal sheets into final forms. They handle thousands of parts per hour.

Why stamping is perfect for high-volume metal parts

Stamping is fast and consistent. This makes it ideal for parts used in mining equipment where accuracy matters and volume is high.

| Operation Type | Function | Example Mining Part |

|---|---|---|

| Blanking | Cuts flat shapes from sheet metal | Mounting plates, covers |

| Bending | Forms angles and curves | Brackets, supports |

| Punching | Creates holes or cutouts | Filter frames, fastener holes |

| Coining | Adds fine surface detail | Logo stamps, surface ridges |

At Prime, we operate 10 stamping lines and deliver ISO-certified stamping parts to clients in North America, Europe, and beyond. Each part is made to tight tolerances to match your drawings or samples.

What is a stamping tool used for?

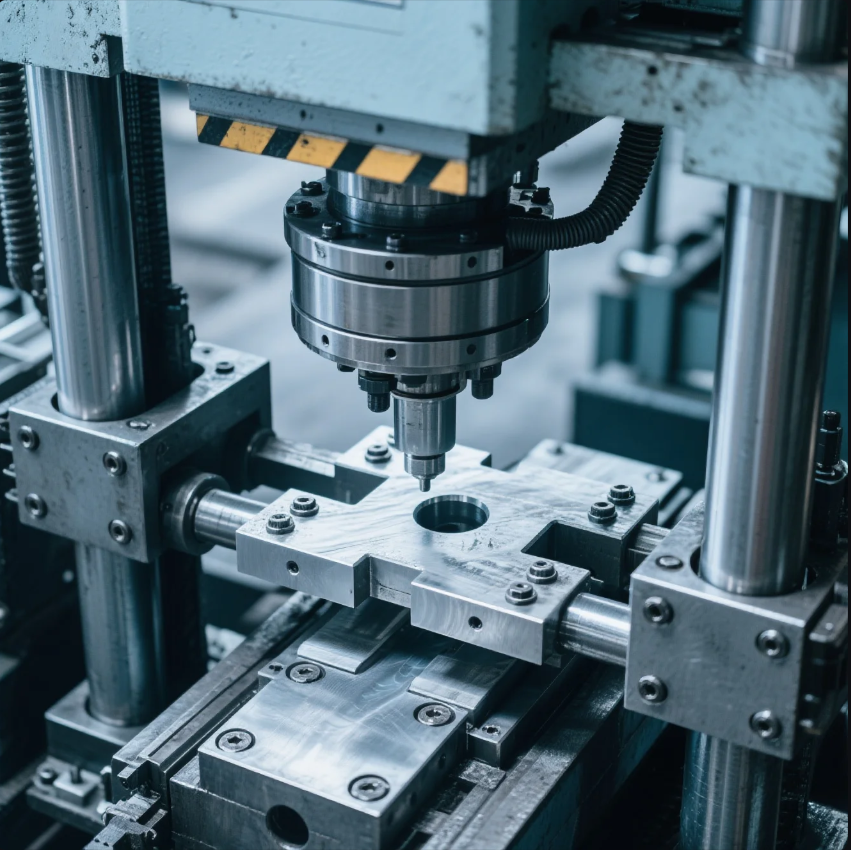

The stamping tool shapes the metal. It’s the most important part of the machine setup.

A stamping tool—also called a die—shapes, cuts, or punches metal. It defines the part’s final shape.

How stamping tools create precision parts

The tool has two main parts: the punch and the die cavity. When the punch presses metal into the cavity, the shape is formed.

| Tool Type | Purpose | Used For |

|---|---|---|

| Progressive Die | Multiple shapes in one stroke | Complex brackets, multiple cuts |

| Compound Die | One-step blanking + punching | Flat parts with holes |

| Transfer Die | Moves part between stages | Large or deep-drawn parts |

We often help clients design custom stamped parts when standard dies don’t match their needs. This helps reduce post-processing and keeps costs low—even for unique parts used in specific mining machines.

How does stamping metal work?

Stamping works through pressure. The machine slams the die down onto sheet metal, shaping it in one quick stroke.

Stamping starts with a flat metal sheet. A die then presses it into shape using force from the press.

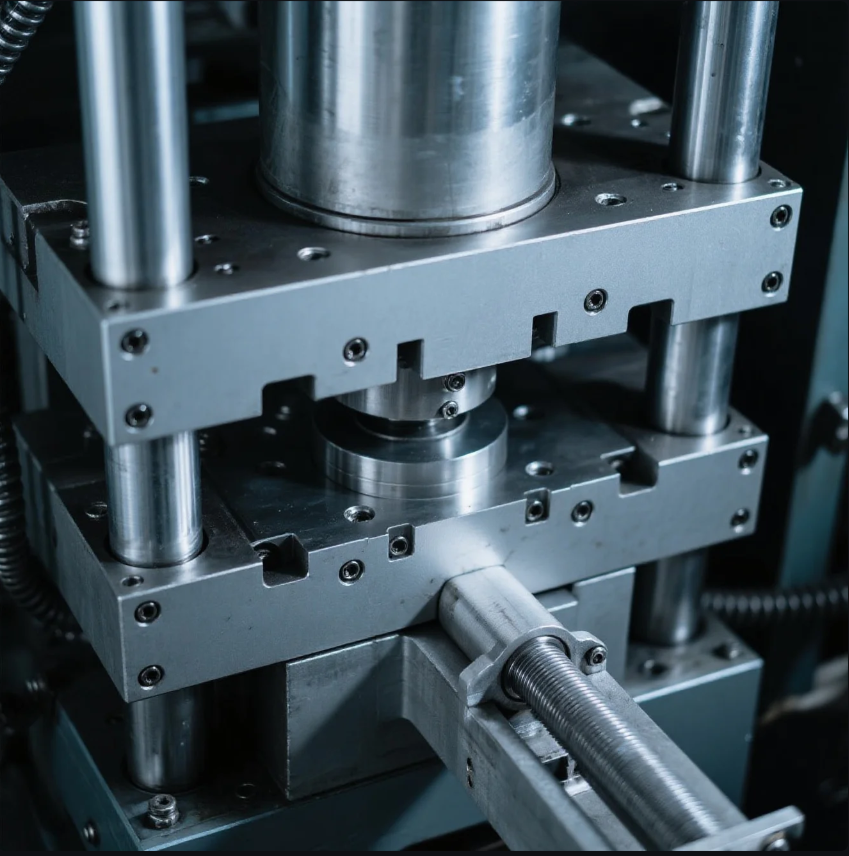

How we stamp mining parts at Prime

We follow a simple, reliable workflow:

- Material Feed: Sheet metal (steel, stainless, aluminum) loaded into the machine

- Die Setup: The right tool is mounted to match the part shape

- Stamping Action: The press forces the punch down into the die

- Part Ejection: Finished part removed, either by automation or manually

- Inspection & Sorting: Each part checked for burrs, cracks, or defects

| Step | Key Outcome |

|---|---|

| Feeding | Steady material flow |

| Forming | Accurate shape + strength |

| Finishing | Smooth edges, good fit |

For extra accuracy, we pair stamping with precision CNC machining for tight-tolerance areas like mounting holes or alignment points.

What is the use of stamping?

Stamping is used to create strong, lightweight parts quickly. It’s ideal for mining and industrial needs.

Stamping is used to make enclosures, brackets, covers, supports, and other structural parts in large volumes.

Why stamping matters in mining and heavy equipment

Mining equipment needs hundreds of stamped components:

- Cover panels to protect electronics

- Mounting brackets for sensors or guards

- Reinforcement plates to add strength

- Stamped fastener bases to reduce assembly time

We help buyers lower costs by switching from machined to stamped designs. With our 20+ years of B2B metal part experience, we know how to optimize for price, strength, and appearance.

| Stamping Benefit | Result for Client |

|---|---|

| Faster production | Shorter lead times |

| Uniform part quality | Easier machine assembly |

| Lightweight but strong parts | Better performance in mobile machines |

| Lower cost per part | Higher margins |

Conclusion

A metal stamping machine forms sheet metal into strong, precise parts—fast and efficiently.

Need a reliable stamping parts supplier with custom tooling and fast delivery? Contact Shandong Prime International Trade Co., Ltd. now. We provide free part design review, quick quotes, and ISO-certified metal stamping parts for your mining or industrial needs. Send us your RFQ today and discover how efficient stamping can be.