What Is a Sealing?

Small leaks can cause big failures in industrial systems.

Sealing is the process of closing gaps to prevent fluid, gas, or solid leakage between surfaces or components.

Without sealing, machines fail faster and maintenance costs rise.

What Is the Meaning of Sealing?

Even tiny leaks can destroy precision equipment.

Sealing means blocking or closing openings to prevent unwanted material from passing through.

Understanding Sealing in Simple Terms

Sealing happens everywhere—from closing food packages to making engines work safely. In industry, it refers to securing the space between two surfaces to control the movement of liquids, gases, or particles.

Key Aspects of Sealing

| Aspect | Why It Matters |

|---|---|

| Leak Prevention | Stops loss of fluids and pressure |

| Protection | Blocks entry of contaminants |

| Safety | Prevents hazardous leaks |

| Efficiency | Improves system performance |

At Prime, we build precision CNC parts, custom fasteners, and ISO-certified components that ensure the sealing process is accurate, reliable, and cost-effective.

What Is a Seal in Mechanical Engineering?

Unsealed systems fail under pressure and stress.

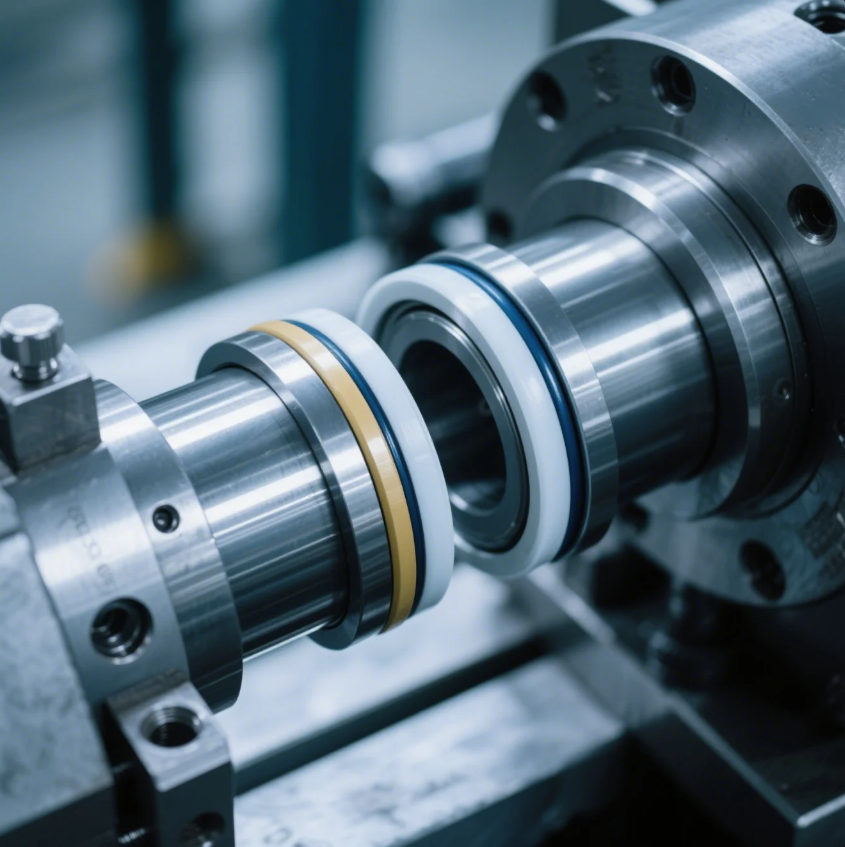

A seal in mechanical engineering is a device or material placed between surfaces to stop fluid or gas movement.

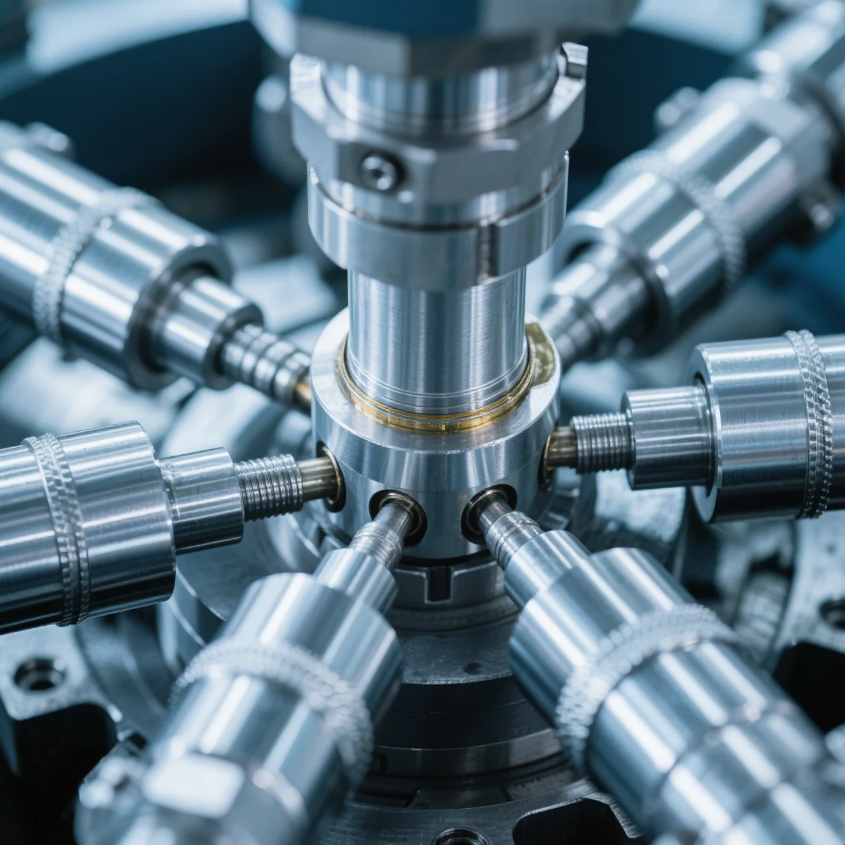

Different Types of Mechanical Seals

In engineering, seals are tailored to the type of motion, pressure, and environment. Common types include:

- Static Seals: Used where parts do not move relative to each other

- Dynamic Seals: Used where surfaces move, like rotating shafts

- Thermal Seals: Protect systems that expand and contract with temperature changes

Common Applications of Seals

| Application | Example Components |

|---|---|

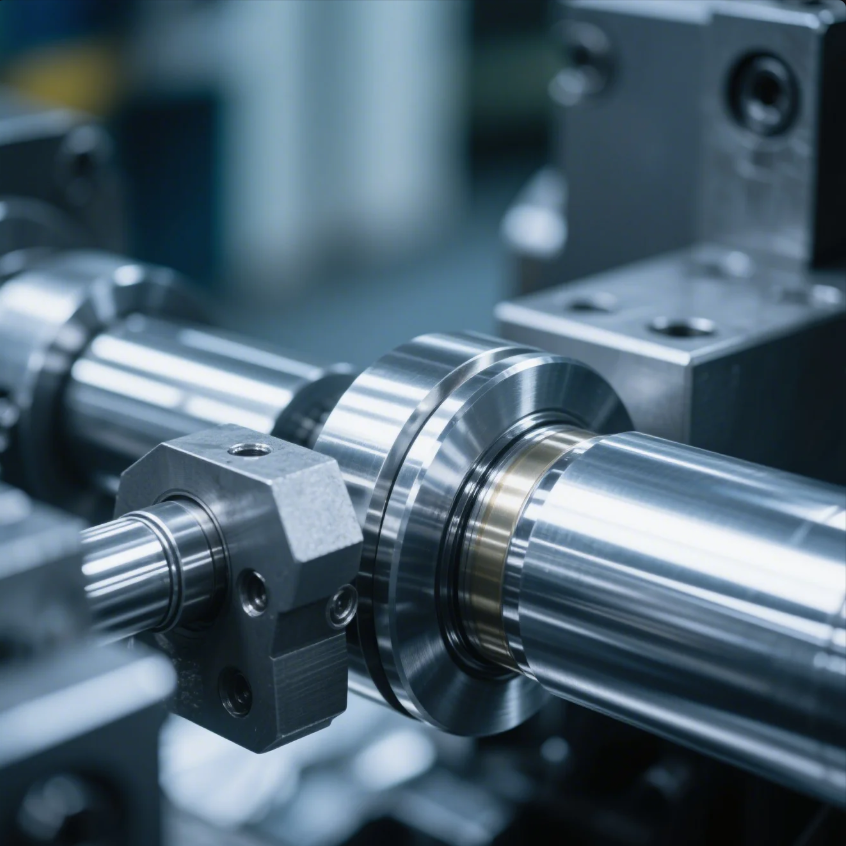

| Hydraulic Systems | Pistons, cylinders |

| Pumps and Valves | Shaft seals, face seals |

| Automotive | Engine gaskets, axle seals |

Prime supplies high-precision stamped parts, custom-molded plastic components, and machined metal rings that are critical in building reliable mechanical seals.

What Is the Purpose of Sealing?

Leaking systems lose money, safety, and time.

The purpose of sealing is to ensure system integrity by preventing leaks, contamination, and mechanical failure.

Why Sealing Is Always a Top Priority

Sealing is not optional. It directly impacts:

- System reliability

- Machine lifespan

- Environmental safety

- Operational efficiency

Good sealing reduces maintenance costs and minimizes downtime. In industries like aerospace, oil and gas, and food processing, a strong seal often means the difference between success and disaster.

Benefits of Professional Sealing

| Benefit | Description |

|---|---|

| Better Performance | Consistent operation and output |

| Reduced Downtime | Fewer leaks and breakdowns |

| Safer Environments | Controlled handling of materials |

| Longer Equipment Life | Less wear and tear on moving parts |

Prime’s custom CNC machining, casting parts, and precision assembly supports help our customers maintain strong, long-lasting seals in the most challenging applications.

What Is Sealing in Engineering?

A weak seal can ruin an entire mechanical system.

Sealing in engineering refers to methods used to create barriers that block fluid, gas, or particles from escaping or entering mechanical systems.

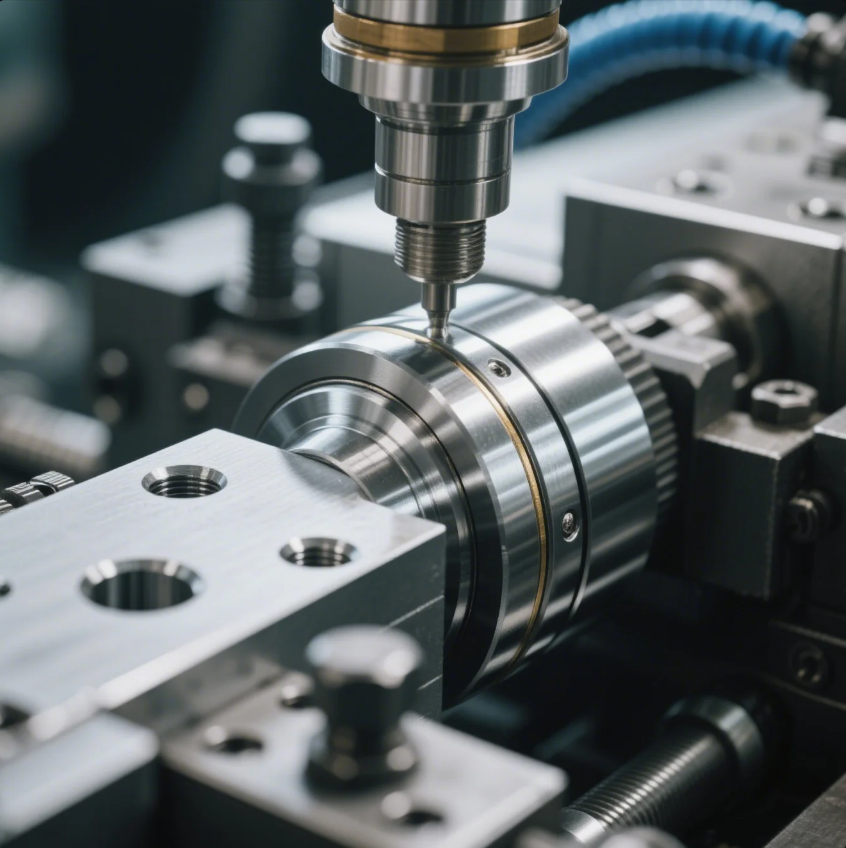

How Engineering Sealing Is Designed

In engineering, sealing solutions must consider:

- Operating pressures

- Temperature cycles

- Chemical exposure

- Mechanical movement

Choosing the right material and design is critical to ensure a long-lasting seal. For dynamic parts like pump shafts, seals must accommodate motion without wearing out too quickly. For static parts like pipes and valves, compression seals are used.

Choosing the Right Sealing Method

| Sealing Method | Best For |

|---|---|

| O-Ring Seals | Static and simple dynamic joints |

| Mechanical Face Seals | High-speed rotating equipment |

| Compression Gaskets | Flanged pipe connections |

| Adhesive Sealants | Complex shapes and lightweight parts |

At Prime, we provide sealing components customized for each industry, ensuring top performance whether you work in manufacturing, automotive, oil and gas, or construction. Our ISO-certified stamping parts, welding pieces, and plastic components are engineered to support the highest sealing standards.

Conclusion

Sealing protects equipment, maintains pressure, and ensures safe, efficient operation in every industry.

Contact Prime today for a free consultation on sealing solutions. With our fast delivery, ISO-certified quality, and custom design services, we can help you secure your systems better and faster than ever before.