What Is Joint Sealing?

Cracks, leaks, or corrosion problems? It usually starts with poorly sealed joints.

Joint sealing protects the integrity of connected materials by blocking moisture, chemicals, and dust from entering.

Discover the real impact of joint sealing and how to choose the best solution for your project.

What Does It Mean to Seal a Joint?

Frustrated by joint failures or structural weakness? You are not alone.

Sealing a joint means applying a material that closes gaps between two surfaces to prevent external damage.

Why Joint Sealing Is a Game-Changer

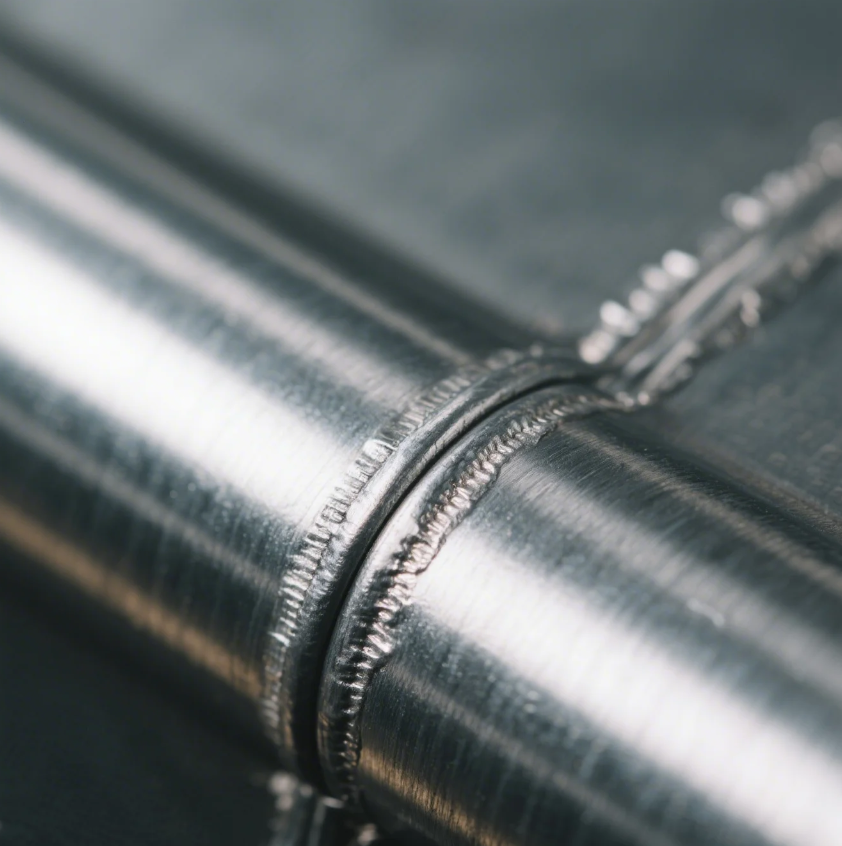

When two surfaces meet, no matter how precisely made, small gaps usually exist. Water, dust, and chemicals find their way inside those gaps. Over time, they corrode, expand, or weaken the parts. Sealing these joints ensures these hazards stay out.

At Prime, with more than two decades of one-stop processing experience for metal stamping parts and precision CNC parts, we know exactly how crucial a perfect seal is.

When Should You Seal a Joint?

| Scenario | Reason for Sealing |

|---|---|

| Exposure to weather | To prevent rust and water infiltration |

| High mechanical load | To distribute stresses evenly |

| Chemical exposure | To block corrosive substances |

| Vibration-prone environments | To absorb shock and prevent cracks |

What Is a Joint Seal?

Tired of hearing about joint damage and costly repairs? Fix it early with the right method.

A joint seal is a protective barrier created by special materials that fill and protect gaps between components.

Understanding the Function of a Joint Seal

A joint seal acts like armor. It stops moisture, gases, and even vibrations from damaging the structure. It also extends the service life of the parts, reduces maintenance costs, and ensures safety.

Important Properties of a Good Joint Seal

| Property | Importance |

|---|---|

| Flexibility | Allows the joint to move without breaking the seal |

| Adhesion | Ensures firm bonding to all surfaces |

| Durability | Withstands harsh weather, chemicals, and aging |

| Compatibility | Matches with metals, plastics, or composites |

At Prime, whether producing custom plastic parts or ISO-certified casting parts, we ensure sealing materials meet strict quality and compatibility requirements.

What Is the Purpose of Joint Sealants?

Frustrated when assemblies break apart too soon? Often it’s because sealing was ignored.

The purpose of joint sealants is to create a flexible, protective layer that prevents intrusion and enhances structural durability.

Why Joint Sealants Are Essential

Joint sealants are not optional. They are critical components in design and production. Ignoring them leads to failures, leaks, corrosion, and even structural collapse.

Primary Goals of Using Sealants:

| Goal | Result |

|---|---|

| Protect internal systems | Keeps water, chemicals, and debris out |

| Allow controlled movement | Joints can expand and contract safely |

| Improve overall lifespan | Reduces replacement and repair costs |

| Maintain appearance | Provides a clean, finished look |

At Prime, providing high-precision CNC parts and customized fasteners means we constantly guide our clients to the best sealing solutions for long-term success.

What Do You Use to Seal Joints?

Choosing random products? It often leads to leaks and damages later.

Materials like silicone, polyurethane, epoxy, and polysulfide are commonly used to effectively seal joints.

Selecting the Best Sealing Materials

The sealing material must match the joint’s environment, stress level, and movement needs. Using the wrong one risks joint failure and shortens the product’s life.

Common Materials Used:

| Material Type | Best Use Case | Special Traits |

|---|---|---|

| Silicone | Exterior CNC parts or plastic joints | Highly flexible and UV resistant |

| Polyurethane | Construction or metal frames | Tough and paintable |

| Epoxy | Heavy-load metal castings | Rigid and chemical resistant |

| Polysulfide | Underwater or chemical processing equipment | Best for water and chemical resistance |

At Prime, during the production of custom stamping parts and welding parts, we advise clients based on environmental conditions and long-term performance requirements.

Conclusion

Sealing joints the right way protects parts, saves costs, and extends service life.

Need expert guidance on sealing your parts?

Prime offers reliable metal stamping parts, custom CNC machining, and ISO-certified casting services, all with professional joint sealing support. Contact us today through our website for a free consultation, tailored solutions, and fast global delivery. Choose Prime for trusted quality and on-time service!