What is machine stamping and why is it essential for modern manufacturing?

Inconsistent quality and slow production times frustrate manufacturers around the globe.

Machine stamping is a high-speed, precision-driven solution for producing consistent metal parts at scale.

Understanding how it works helps you choose the right supplier and avoid costly errors.

LOOP_START

What is stamping machining?

Buyers often face poor repeatability and rising labor costs with traditional manufacturing methods.

Stamping machining uses custom dies and mechanical presses to quickly shape metal sheets with consistent accuracy.

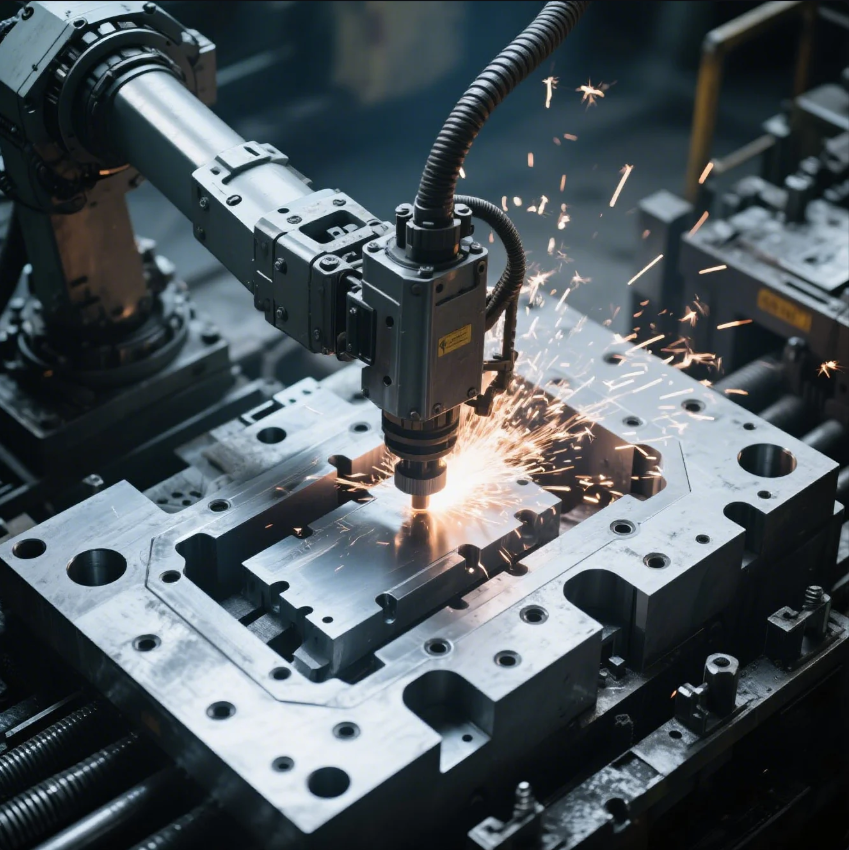

What exactly happens during stamping machining?

Stamping machining is a cold forming process that transforms flat sheet metal into parts by applying force through a punch and die. This allows for complex shapes, clean edges, and tight tolerances—all done at high speed.

What makes it better?

| Feature | Stamping Machining |

|---|---|

| Speed | 500–1,500 parts per hour |

| Precision | ±0.01 mm achievable tolerance |

| Cost-efficiency | High ROI for medium to large volumes |

| Material versatility | Steel, aluminum, brass, copper, etc. |

| Eco-efficiency | Minimal waste and energy-efficient process |

Why our stamping process stands out

At Prime, we’ve run stamping lines since 1993. Our 10 production lines are optimized for high-volume precision. We’ve supported industries from automotive to agriculture. Each project receives CAD-based die design and real-time production monitoring—ensuring consistent output and rapid lead times.

LOOP_END

LOOP_START

What is the meaning of stamp machine?

Many confuse stamping machines with hydraulic presses or manual forming tools.

A stamp machine is a mechanical or hydraulic system that forms metal sheets using pressure and a tool called a die.

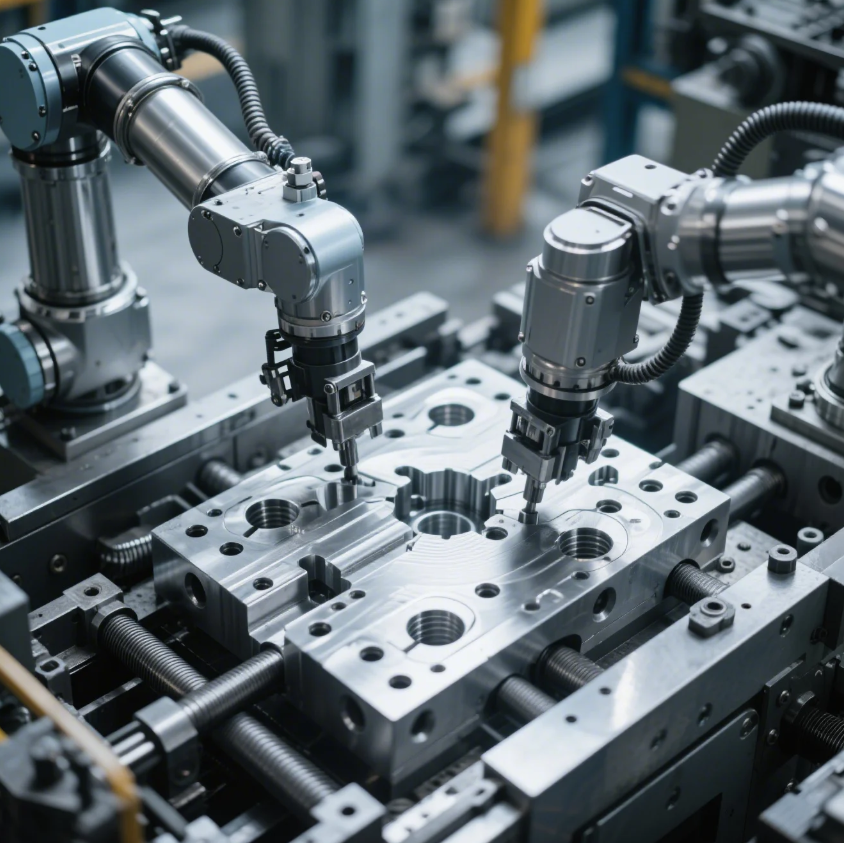

Components of a professional stamp machine

A typical industrial stamp machine includes:

- Press body – applies vertical force

- Die set – custom tool that defines the part shape

- Feeding system – automates sheet placement

- Control unit – monitors speed, pressure, and alignment

Types of stamping machines

| Machine Type | Description | Best For |

|---|---|---|

| Mechanical Press | Uses flywheel-driven crankshaft for high-speed output | Thin gauge materials, high volumes |

| Hydraulic Press | Uses fluid pressure, slower but stronger | Thick materials, deeper draws |

| Servo Press | Offers programmable control and adaptive force curves | Complex geometries, premium finishes |

Our advantage: Automation + Accuracy

At Prime, every machine is calibrated to handle a range of materials and thicknesses. With our servo-controlled presses, we handle intricate fasteners and brackets with micro-level accuracy—ideal for electronics and aerospace industries. This investment in precision directly reduces part rejections and improves your bottom line.

LOOP_END

LOOP_START

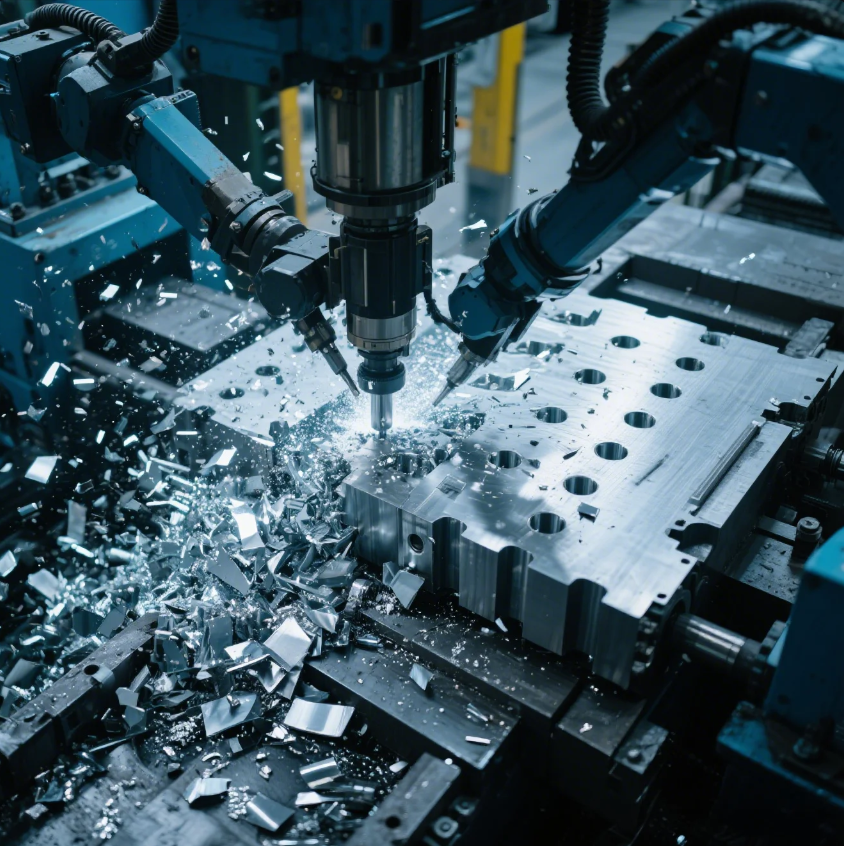

What is stamping used for?

Engineers often underestimate how many industries rely on stamped parts for critical components.

Stamping is used to create functional, structural, and aesthetic parts across every major manufacturing sector.

Key application examples

| Industry | Common Stamped Parts |

|---|---|

| Automotive | Reinforcements, chassis clips, trim parts |

| Electronics | EMI shields, battery tabs, contact terminals |

| Appliances | Handles, panels, internal brackets |

| Construction | Connectors, anchors, metal joist hangers |

| Industrial Equipment | Mounting bases, structural joints |

Why versatility matters

Stamping can produce everything from simple washers to highly detailed enclosures. For example, one of our North American clients needed customized stainless steel brackets with ±0.02mm tolerance. We used progressive stamping tools, completed the order in 18 days, and kept packaging damage to zero during air freight.

Our value-added services include:

- Secondary machining

- Surface finishing (powder coat, zinc plating)

- Laser marking or engraving

- Kitting and bulk packaging

LOOP_END

LOOP_START

What is the difference between stamping and pressing?

Many clients use "pressing" and "stamping" interchangeably, but they have different technical meanings.

Stamping is a precise forming process using dies, while pressing is a broader term that covers many force-based operations.

Side-by-side comparison

| Aspect | Stamping | Pressing |

|---|---|---|

| Definition | Die-based shaping of metal sheets | General term for applying force |

| Tooling | Custom punch and die | Flat or contoured pressing surfaces |

| Accuracy | Very high with tight tolerances | Varies depending on process |

| Use Cases | Precision parts, aesthetic components | Bending, joining, low-spec shapes |

Why this matters for sourcing

Knowing the right term helps avoid delays. I’ve had buyers ask for "pressed fasteners," but what they needed was high-precision stamped parts. That’s why at Prime, we consult deeply with our clients before production—especially when they want ISO-certified stamping, tightly packed fasteners, or CNC-assisted components.

This clarity helps reduce errors and increase production speed.

LOOP_END

Conclusion

Stamping is essential for precision, speed, and scalability in metal component manufacturing.

Ready to streamline your metal part sourcing? Reach out to Prime today for a free consultation, competitive quote, and custom-tailored stamping solution. With ISO-certified quality, rapid delivery, and 20+ years of experience, we’re ready to be your trusted partner.