What is sheet metal and what is it used for?

Many buyers feel confused when sourcing sheet metal parts.

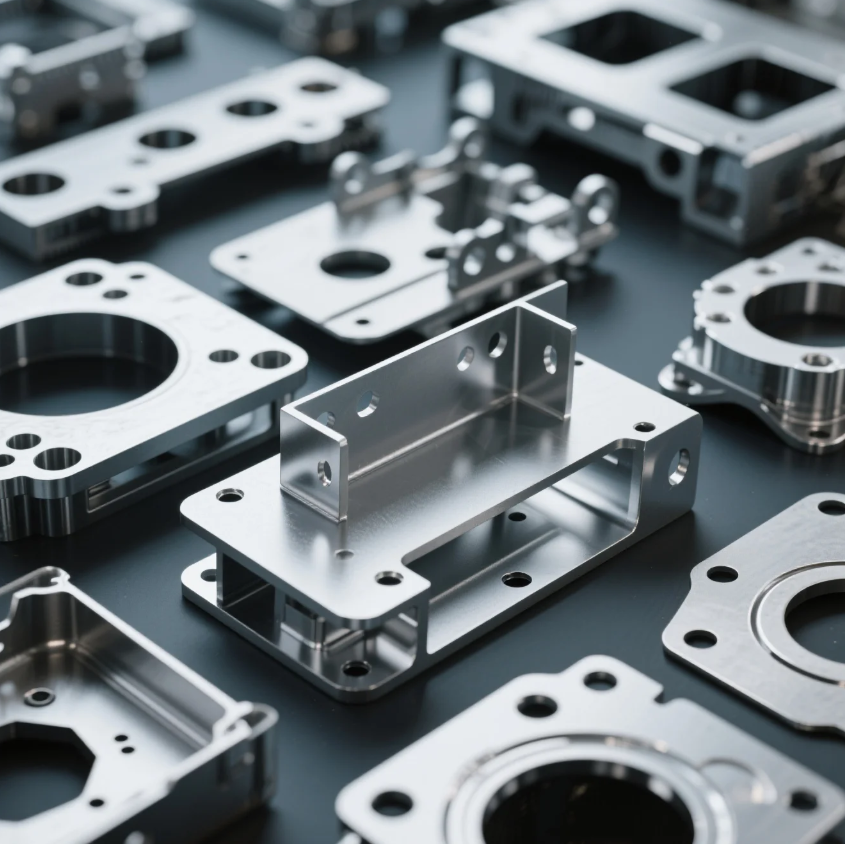

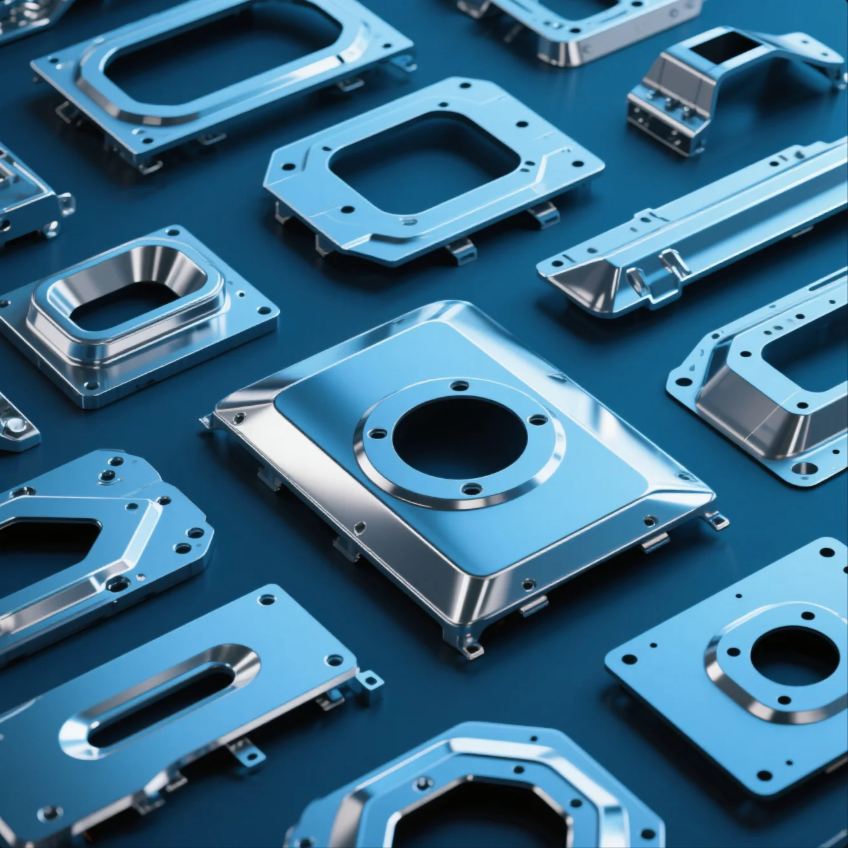

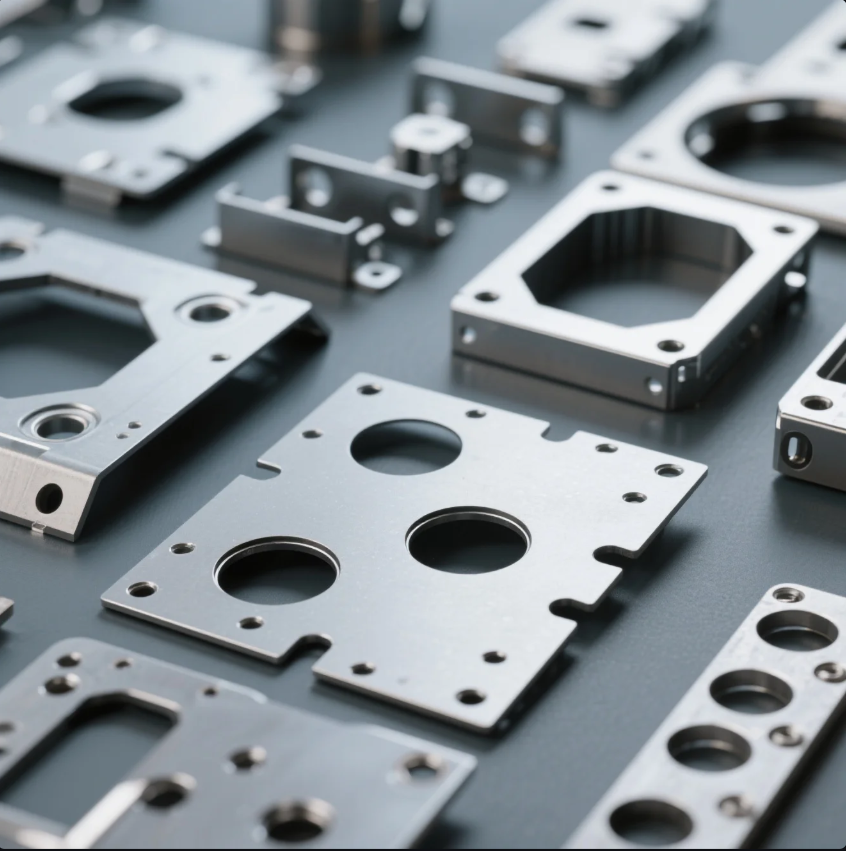

Sheet metal is a flat, thin piece of metal shaped through industrial processes. It is widely used in construction, electronics, and machinery.

Without understanding its applications, buyers often make costly sourcing mistakes. Let’s fix that now.

What is sheet metal work used for?

Buyers often overlook how many everyday products involve sheet metal.

Sheet metal work is used to make car parts, machine enclosures, building panels, and HVAC components. It’s also used in electronics and agriculture.

Sheet metal is easy to cut, bend, and join. This makes it ideal for custom industrial applications. At Prime, we produce high-precision stamping parts for various sectors. Our clients include engineers and procurement officers in automotive, construction, and energy fields. Thanks to our 10 in-house production lines, we handle large orders fast and efficiently.

Common Industries Using Sheet Metal

| Industry | Application Examples |

|---|---|

| Automotive | Car frames, panels, heat shields |

| HVAC | Ducts, vents, system housings |

| Electronics | Mounts, casings, brackets |

| Construction | Roofs, wall covers, structural supports |

| Agriculture | Machine shields, protective enclosures |

We support custom designs and complex specs. Our ISO-certified processes guarantee stable quality across batches.

What is the difference between sheet metal and fabrication?

Many buyers use these terms interchangeably. That leads to confusion.

Sheet metal is a raw material. Fabrication is the process of turning it into parts or assemblies.

Sheet metal starts as flat material. Fabrication adds value through forming, cutting, and welding. At Prime, we manage both stages. We offer full-service metal part production including CNC machining, welding, and surface treatment. Our clients benefit from better control, shorter lead times, and cost-effective production.

Key Differences Between Sheet Metal and Fabrication

| Term | Meaning | Role in Production |

|---|---|---|

| Sheet Metal | Flat metal sheets | Material base |

| Fabrication | Cutting, shaping, assembling process | Turns material into end-use parts |

| Focus | Thickness, grade, dimensions | Functionality and performance |

| Output | Blanks or semi-finished stock | Ready-to-install components |

We help clients get it right from the start. With strong communication and clear production steps, our customers avoid delays and hidden costs.

Why do people use sheet metal?

Buyers want strong, low-cost solutions. Sheet metal fits both needs.

People use sheet metal because it’s durable, easy to form, low-cost, and great for custom parts.

Sheet metal is strong enough for structural use. It’s light enough for mobile applications. It also allows for fast shaping, minimal waste, and low material costs. That’s why many industries use it—from electronics to heavy equipment. At Prime, we help customers create precision CNC parts and custom brackets using high-grade metal sheets. We handle both small-batch and high-volume production.

Key Advantages of Sheet Metal

- Excellent strength-to-weight ratio

- Easy to bend, weld, or stamp

- Works for simple or complex parts

- Ideal for rapid prototyping

- Cost-effective for long-term production

We also provide complete packaging and labeling. That protects your goods during transit and meets your branding needs.

What is sheet metal forming used for?

Buyers often ask how we turn flat metal into 3D parts.

Sheet metal forming shapes metal using pressure or dies. It’s used to produce cabinets, panels, brackets, and covers.

Forming includes bending, drawing, and punching. It gives the final shape and function to each part. At Prime, we use modern CNC forming systems to ensure consistency. Our stamping parts meet tight tolerances and complex requirements. Customers from Europe and the US trust us for large-volume forming projects. We deliver quickly and meet all ISO quality standards.

Common Forming Methods

| Method | What It Does |

|---|---|

| Bending | Creates angles and folds |

| Punching | Cuts holes or shapes |

| Drawing | Pulls metal into a mold or die |

| Stamping | Forms patterns or shapes with pressure |

We develop our own molds and fixtures. That helps clients reduce lead times and get their products faster. Our forming services are also fully customizable—from simple enclosures to precision brackets.

Conclusion

Sheet metal offers strength, flexibility, and efficiency for modern industrial needs.

Need fast, custom metal components? Contact Prime today for a free quote. We offer expert consultation, fast global shipping, and ISO-certified quality. Let’s start building your next project—on time and on budget.