What Is Sheet Metal Stamping?

Not sure how sheet metal becomes a finished part so quickly?

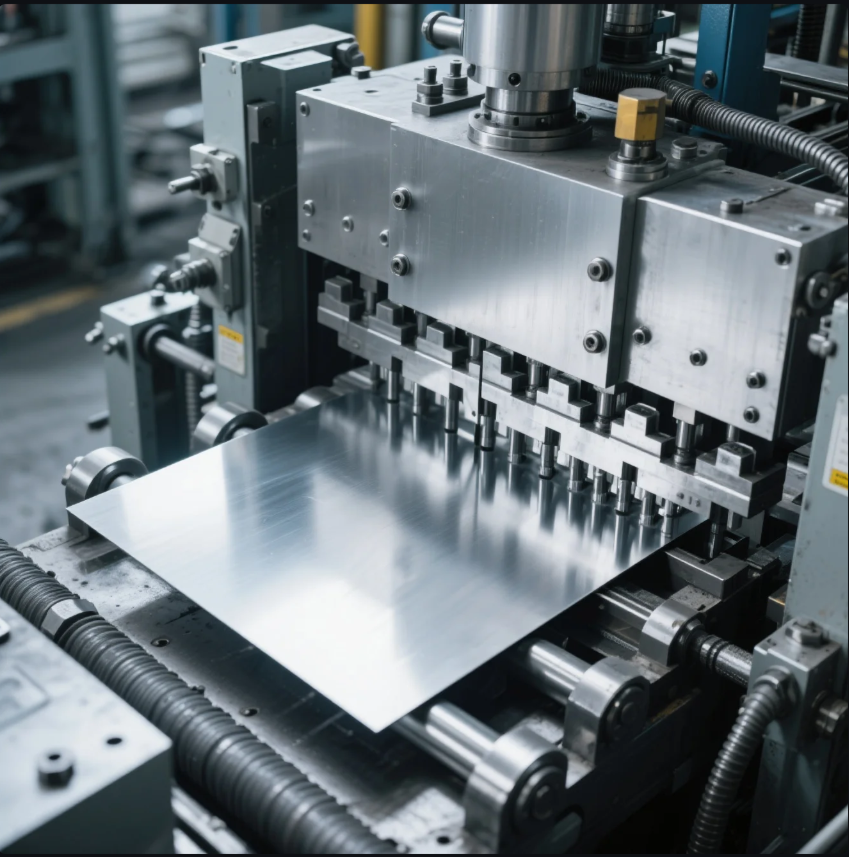

Sheet metal stamping uses a punch and die to press flat metal into specific shapes. It’s fast, cost-effective, and ideal for large-scale production.

Many buyers confuse stamping with forging or bending. But stamping is unique—especially in high-volume part production. In this guide, I’ll break it down clearly.

What are the four types of metal stamping?

Many clients ask which stamping method fits their design. Choosing the wrong one can raise costs or cause defects.

The four main stamping types are progressive die stamping, compound stamping, transfer die stamping, and four-slide stamping. Each suits different part shapes and production volumes.

For example, a customer once requested compound stamping for a part that needed multiple bends. We suggested progressive stamping instead. That cut their lead time by 30%.

Overview of Stamping Types

| Stamping Type | Best For | Key Benefit |

|---|---|---|

| Progressive Die | High-volume, multi-step parts | Fast output per stroke |

| Compound Die | Simple shapes, single stroke | Cuts and forms together |

| Transfer Die | Large parts, multiple stages | Good for large equipment |

| Four-Slide | Small, complex parts | High flexibility, compact |

Prime’s Stamping Capabilities

As a custom stamping parts supplier, Prime handles all four methods. With in-house die design, we choose the most efficient stamping solution to meet tight deadlines and budgets.

What is the difference between forging and stamping?

Some clients ask if stamping is the same as forging. It’s not.

Stamping shapes flat metal sheets using a press and die. Forging reshapes solid metal using heat and force. The processes use different materials, tools, and purposes.

Forging creates very strong, thick parts. Stamping is best for precise, lightweight components. One of my customers moved from forged to stamped brackets to cut costs without sacrificing function.

Stamping vs. Forging

| Feature | Stamping | Forging |

|---|---|---|

| Material | Sheet metal | Solid metal bar or billet |

| Process | Cold, press-based | Hot or warm with hammer/die |

| Volume Efficiency | High-volume, repeatable | Lower-volume, durable parts |

| Best Use | Covers, clips, enclosures | Gears, shafts, heavy tools |

Why Choose Stamping?

If your product needs high volume, tight tolerances, and clean surface finishes, metal stamping is the better choice. Prime offers both ISO-certified stamping and quick tooling support.

What is meant by stamping process?

The stamping process seems simple—but it includes many precise steps.

Stamping is the process of placing flat sheet metal into a stamping press, where a tool and die form the metal into a specific shape through pressure.

This process can include bending, punching, coining, or flanging. Each action is completed in one or multiple press strokes. We’ve helped clients optimize designs for faster stamping—saving up to 25% on cost.

Key Elements of the Stamping Process

| Element | Role in the Process |

|---|---|

| Die Set | Defines shape and tolerances |

| Punch Tool | Applies force to form metal |

| Press Machine | Delivers mechanical or hydraulic pressure |

| Sheet Material | Must match thickness specs |

Prime’s Control Over the Process

With 10 lines running around the clock, Prime controls every step—from die design to press calibration. That allows us to offer fast delivery of stamped parts, even with tight tolerances or complex geometries.

What are the 7 steps in the stamping method?

Many buyers think stamping is just one step—but it involves more.

The full stamping process includes 7 key steps: blanking, punching, bending, coining, embossing, flanging, and finishing. Not all parts use every step, but most require several.

I once worked with a client who only planned for blanking and bending. After adding embossing for their logo and flanging for rigidity, their part quality improved dramatically.

7-Step Stamping Flow

| Step | Purpose |

|---|---|

| 1. Blanking | Cuts raw sheet into part shape |

| 2. Punching | Makes holes or cut-outs |

| 3. Bending | Forms metal into angles |

| 4. Coining | Adds precise details or logos |

| 5. Embossing | Raises or depresses surface shapes |

| 6. Flanging | Strengthens edges or adds tabs |

| 7. Finishing | Removes burrs, adds coatings |

Why Prime Delivers Complete Stamping Solutions

As an ISO-certified stamping manufacturer, we handle all seven steps with precision. Our in-house team ensures every press stroke meets your specs. From sample to shipment, we focus on speed, quality, and packaging safety.

Conclusion

Sheet metal stamping forms parts by pressing metal sheets into shape with dies and punches.

Ready to source reliable stamped parts? Contact Prime for a free quote, quick sample, and technical advice. Our 20+ years of experience and ISO systems ensure precise parts, fast delivery, and secure packaging—shipped worldwide.