What is the best bend radius for sheet metal?

Using the wrong bend radius can lead to cracked parts, poor fits, or tool damage.

The best bend radius for sheet metal is equal to the material thickness. This rule balances formability, durability, and part precision.

At Prime, we use this standard on all CNC-bent and stamped parts, ensuring accurate bends and minimal rework for our global clients.

What should be the bend radius of sheet metal?

Bends that are too tight can break or warp the part.

The minimum inside bend radius should be at least 1× the material thickness. For tougher metals like stainless steel, use 1.5× or more.

At Prime, we adjust bend radius by material type and part function—ensuring every bend performs well in real-world conditions.

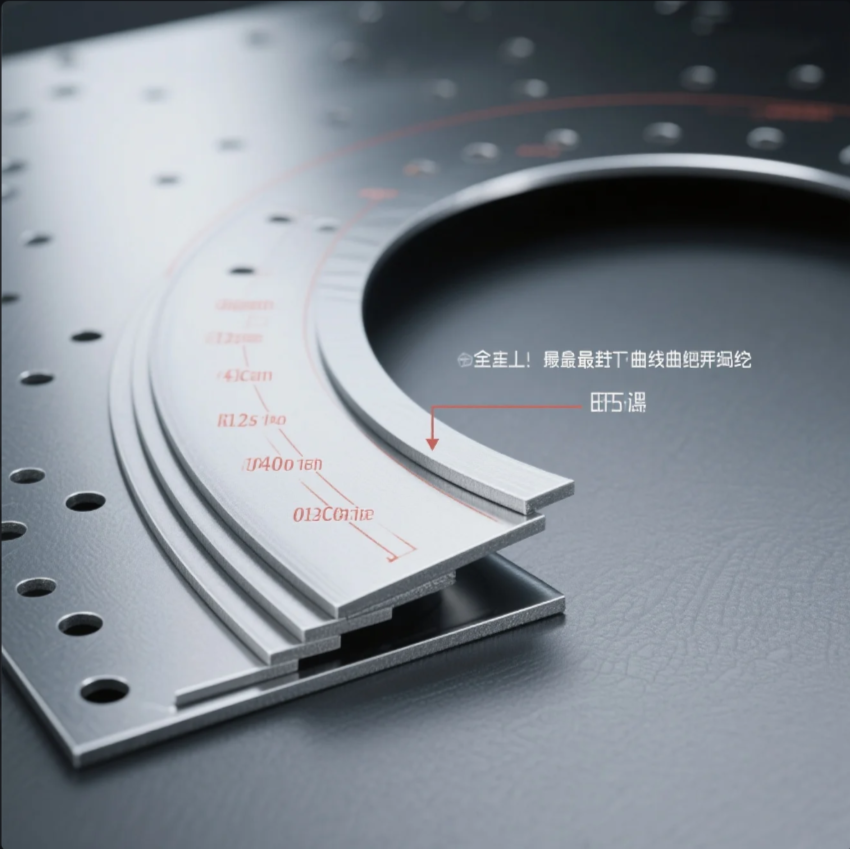

Recommended Bend Radius by Material

| Material | Suggested Bend Radius |

|---|---|

| Mild Steel | 1× material thickness |

| Aluminum | 1.5× material thickness |

| Stainless Steel | 1.5–2× material thickness |

| Copper | 1–1.5× material thickness |

Our team also validates each design with bending simulations before production starts.

What is the recommended bend radius?

There’s no one-size-fits-all radius—but the baseline is simple.

Use a bend radius of 1× thickness for soft materials. For harder alloys or cosmetic finishes, increase the radius to reduce cracking or marring.

At Prime, we fine-tune the radius during tooling setup to match press brake tonnage, tooling die, and material response.

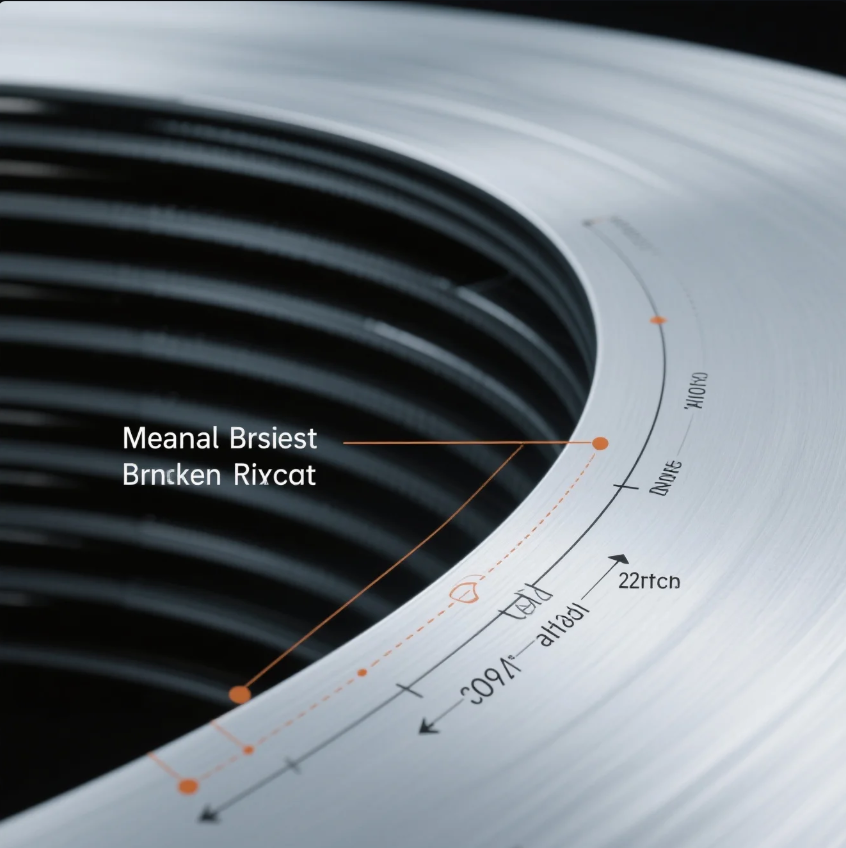

General Bend Radius Rule

| Thickness (mm) | Recommended Radius |

|---|---|

| 0.8 mm | 0.8 – 1.2 mm |

| 1.5 mm | 1.5 – 2.25 mm |

| 2.0 mm | 2.0 – 3.0 mm |

| 3.0 mm | 3.0 – 4.5 mm |

These values are ideal for reducing springback and achieving precise angles.

What is the rule of thumb for bend radius?

Need a quick rule to guide your design?

The bend radius should be equal to or greater than the sheet thickness. That’s the universal starting point for most metals.

At Prime, we use this rule in all early-stage design reviews to avoid back-and-forth during production quoting.

Rule of Thumb Summary

- Inside radius ≥ 1× material thickness

- For high-strength materials: use ≥ 1.5× thickness

- For cosmetic bends: use soft tools or larger radii

Need tighter folds? We can review your drawing and recommend tooling upgrades or alternate alloys.

What size corner relief for sheet metal?

Sharp corners near bends? You’ll need relief to avoid cracks.

The corner relief should be at least 1× the material thickness in width, and 1.5× in length. This prevents tearing or bulging during bending.

At Prime, we insert proper corner reliefs during DFM checks—especially for formed brackets and enclosures.

Standard Corner Relief Dimensions

| Material Thickness | Relief Width | Relief Length |

|---|---|---|

| 1.0 mm | 1.0 mm | 1.5 mm |

| 1.5 mm | 1.5 mm | 2.0 mm |

| 2.0 mm | 2.0 mm | 3.0 mm |

| 3.0 mm | 3.0 mm | 4.5 mm |

Proper relief avoids tool wear and improves flange alignment during assembly.

Conclusion

The best bend radius for sheet metal is 1× material thickness—adjusted based on alloy and part use.

Need help designing the perfect bends? Prime offers free DFM checks, precision forming, and ISO-certified fabrication. Contact us today for a custom quote and expert advice on your next metal part.