What is the best rod to weld sheet metal?

Using the wrong welding rod can warp or crack your sheet metal.

6013 welding rods are the best choice for thin sheet metal. They provide smooth, low-penetration welds that reduce the risk of burn-through.

At Prime, we choose welding rods based on material thickness, joint type, and application—so your parts hold up under pressure.

Which is better, 6011 or 7018?

Both are popular—but not ideal for thin sheet metal.

6011 rods penetrate deeply and work on dirty or rusty metals. 7018 rods create strong, low-spatter welds but require clean surfaces and preheat for thin sheets.

For sheet metal under 3mm, neither is perfect. At Prime, we prefer 6013 or TIG welding for precision metal enclosures and custom brackets.

6011 vs. 7018 Overview

| Rod Type | Strengths | Weaknesses |

|---|---|---|

| 6011 | Good for dirty/rusty metal, deep fusion | Harsh on thin sheets, more spatter |

| 7018 | Smooth arc, strong welds, low hydrogen | Needs dry storage, can burn through |

For critical welds on thin material, 6013 or TIG is a safer choice.

What kind of welder do you use for sheet metal?

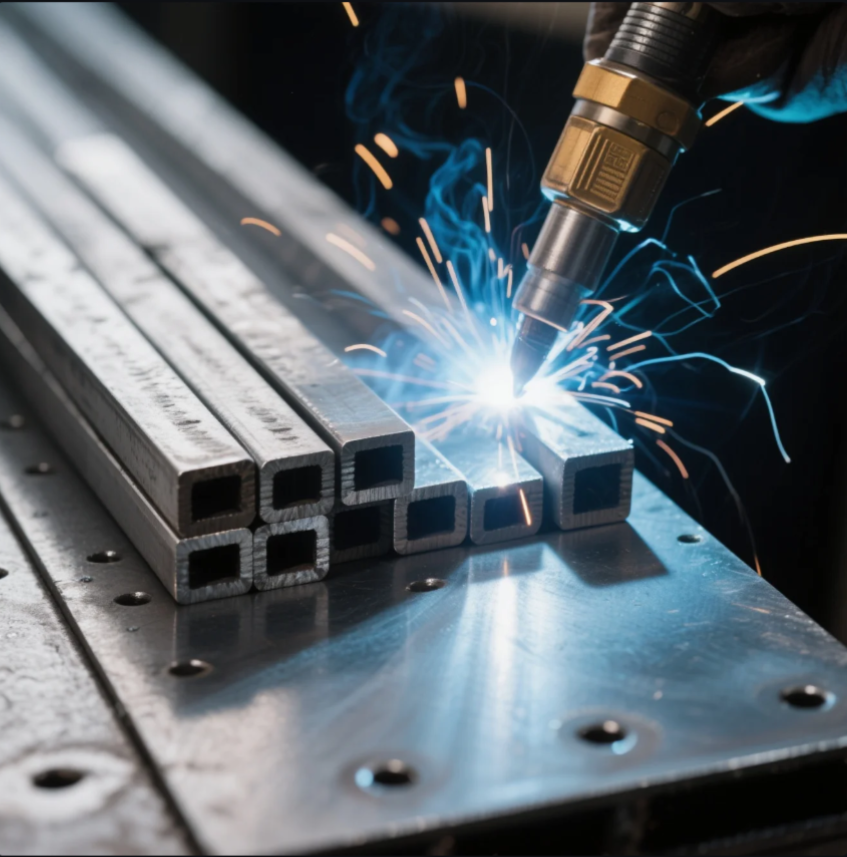

Not all welders can handle thin materials without distortion.

TIG welders are ideal for sheet metal due to their precise heat control. MIG welders are suitable for faster jobs with slightly thicker sheets.

At Prime, we use TIG welding for aluminum, stainless steel, and low-carbon sheet parts. For medium-thickness parts, MIG helps us scale production while maintaining strength.

Welder Types for Sheet Metal

| Welder Type | Best Use Case | Pros |

|---|---|---|

| TIG | Thin, cosmetic, or complex welds | Clean finish, low heat input |

| MIG | Medium-thickness or high-volume parts | Fast, cost-efficient |

| Stick | Rarely used—too aggressive for sheet metal | High penetration, less precision |

We always select the machine and rod that match your design’s needs, not just the shop’s convenience.

What’s the difference between 7018 and 7014 welding rods?

They may look similar, but they behave differently under the arc.

7018 rods create high-strength, low-hydrogen welds. 7014 rods are easier to strike and use on mild steel with less prep.

For structural parts, 7018 is stronger. For simple welds on clean sheet metal, 7014 is easier and more forgiving.

7018 vs. 7014 Welding Rods

| Feature | 7018 Rod | 7014 Rod |

|---|---|---|

| Strength | High strength, low hydrogen | Medium strength |

| Arc Stability | Very stable with proper storage | Easy start, good for DIY or beginners |

| Use Case | Structural welds, pressure vessels | Light fabrication, mild steel sheets |

At Prime, we only use these rods for thick sections—not typical sheet metal. For most thin jobs, we opt for TIG or 6013 rods.

What are 6013 rods used for?

This is the go-to rod for clean, thin materials.

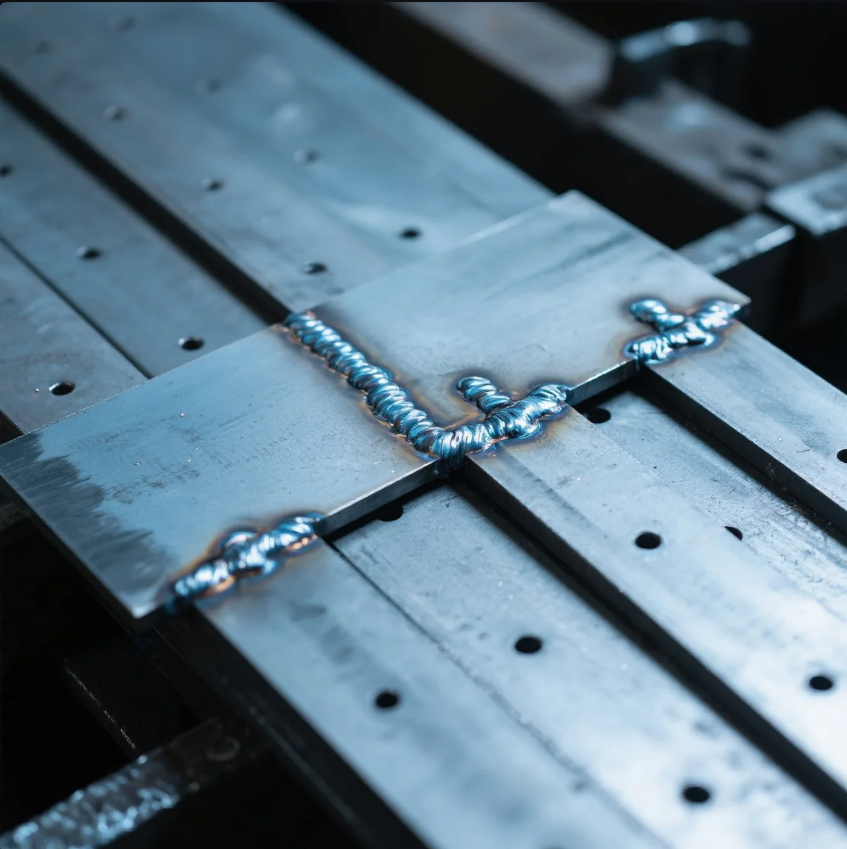

6013 rods are perfect for light sheet metal, furniture frames, and mild steel enclosures. They provide a soft arc with easy slag removal.

At Prime, we use 6013 when clients request low-cost mild steel parts that don’t require deep weld penetration or extreme strength.

6013 Rod Features

| Property | Benefit |

|---|---|

| Soft Arc | Minimizes burn-through on thin metal |

| Easy Slag Removal | Speeds up post-weld cleanup |

| Low Spatter | Creates clean finishes for appearance |

This rod works well with AC or DC welders and is easy to control—making it ideal for consistent, neat results.

Conclusion

6013 welding rods are best for sheet metal due to their control and clean arc.

Need precision-welded parts with the right process and rod? Prime delivers ISO-certified sheet metal assemblies, TIG welds, and accurate finishes—customized to your design. Contact us now for a fast quote and expert consultation.