What is the best tool to cut metal?

Cutting metal requires the right tool for speed, precision, and material thickness.

The best tool to cut metal depends on the job. Plasma cutters are fastest. Laser cutters offer precision. Saws and shears handle structure and volume.

In this post, I’ll explain the most effective metal cutting tools used in industrial settings—and how we at Prime choose the right machine to deliver precise, reliable parts on time.

What is the best tool to use to cut metal?

There’s no one best tool—it depends on the material, shape, and accuracy you need.

For thin and precise cuts, use a laser cutter. For speed, use a plasma cutter. For structure, use a band saw or shear.

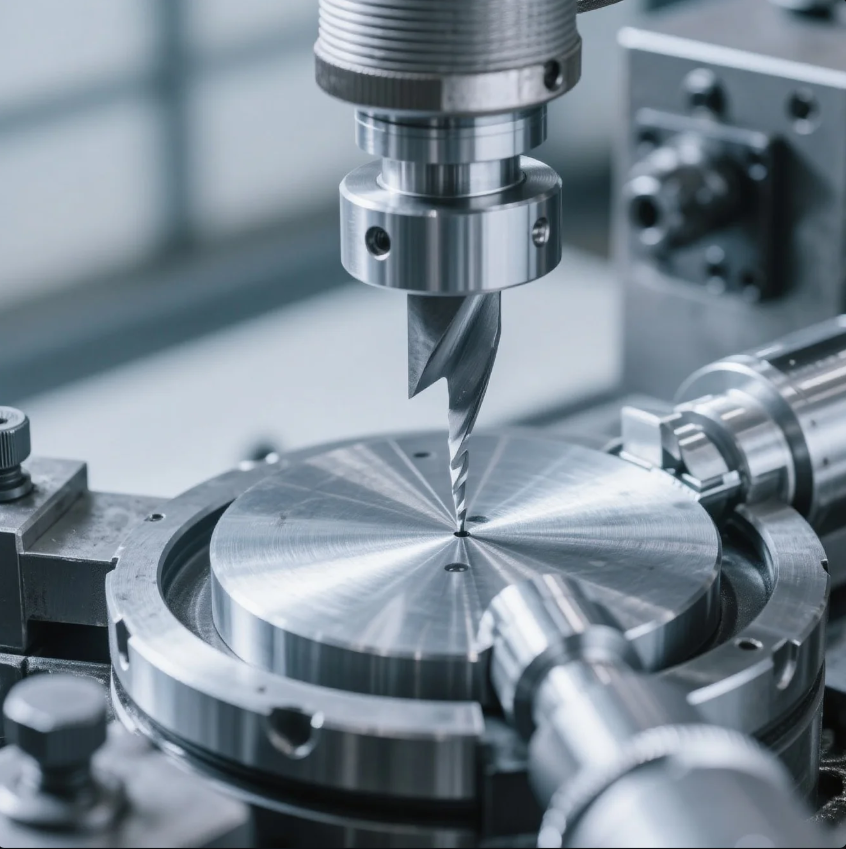

How to choose the right cutting tool

| Tool Type | Best For | Strengths |

|---|---|---|

| Laser Cutter | Precision sheet cutting | High accuracy, minimal heat distortion |

| Plasma Cutter | Thick plate cutting | Fast, powerful |

| Band Saw | Tubes, rods, profiles | Clean, structural cuts |

| Hydraulic Shear | Large sheet trimming | Fast straight cuts |

At Prime, we combine laser cutting and CNC machining for high-precision results—especially for industrial and mining applications.

What is the most common used metal cutting tool?

The band saw is the most common cutting tool in industrial metalwork.

Band saws are widely used because they’re versatile, cost-effective, and clean-cutting for many metal types.

Why band saws are so popular

They’re reliable and easy to maintain. Here’s how they compare:

| Saw Type | Common Use | Advantage |

|---|---|---|

| Horizontal Band Saw | Straight bar or pipe cutting | Accurate length cuts, fast output |

| Vertical Band Saw | Manual curves and complex shapes | Better for hand-guided control |

At Prime, we use automated band saws for structural steel, then follow up with precision machining or custom stamping to match your drawings.

What is the fastest way to cut metal?

Speed matters for high-volume production. Plasma cutters lead when time is tight.

Plasma cutting is the fastest way to cut thick metal plates. It uses high-temperature ionized gas to melt metal quickly.

When speed beats precision

Plasma cutting is ideal for:

- Rough layout cuts

- Heavy steel jobs

- Pre-welding prep

| Tool Type | Cutting Speed | Typical Use |

|---|---|---|

| Plasma Cutter | Very high | Fast production of large metal parts |

| Hydraulic Shear | High | Quick flat sheet trimming |

| Chop Saw | Medium | On-site or short-length cutting |

We often recommend plasma cutting when turnaround speed is critical and edge perfection isn’t required.

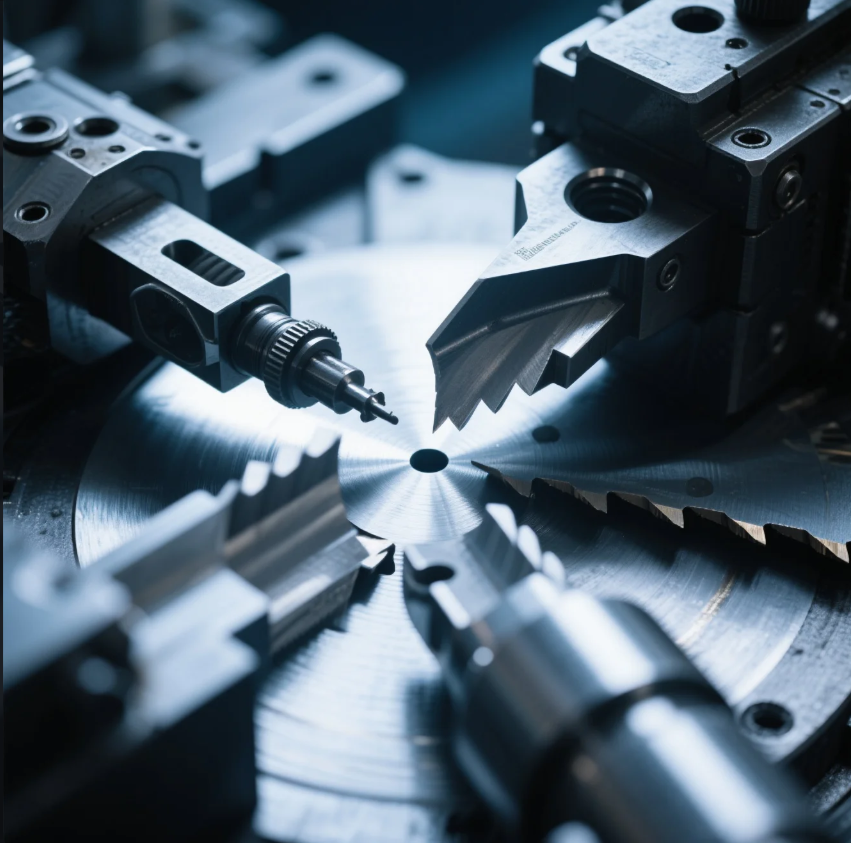

What machines can cut metal?

There are many machines for cutting metal, from basic to high-tech.

Machines that cut metal include laser cutters, plasma cutters, waterjets, shears, and saws.

Cutting machines used in Prime’s factory

| Machine Type | Cutting Method | Applications |

|---|---|---|

| CNC Laser Cutter | Focused laser beam | Precision brackets, covers, housings |

| Plasma Cutter | Plasma arc | Thick steel plates, heavy components |

| Hydraulic Shear | Blade shearing | Flat panel cutting, large batches |

| Band Saw | Continuous blade cutting | Tubes, bars, profiles |

| Waterjet Cutter | Abrasive water jet | Heat-sensitive alloys, thick shapes |

Thanks to our 10 production lines, Prime offers integrated cutting, stamping, and machining services—all under one roof. Our team ensures fast delivery, accurate cuts, and ISO-certified quality.

Conclusion

Choose your metal cutting tool based on material, speed, and precision. At scale, the right choice saves time and money.

Need fast, accurate metal cutting for your industrial project? Contact Shandong Prime International Trade Co., Ltd. today. We offer custom cutting solutions, free design consultation, and global delivery for all your metal parts. Let us help you cut smarter—starting today.