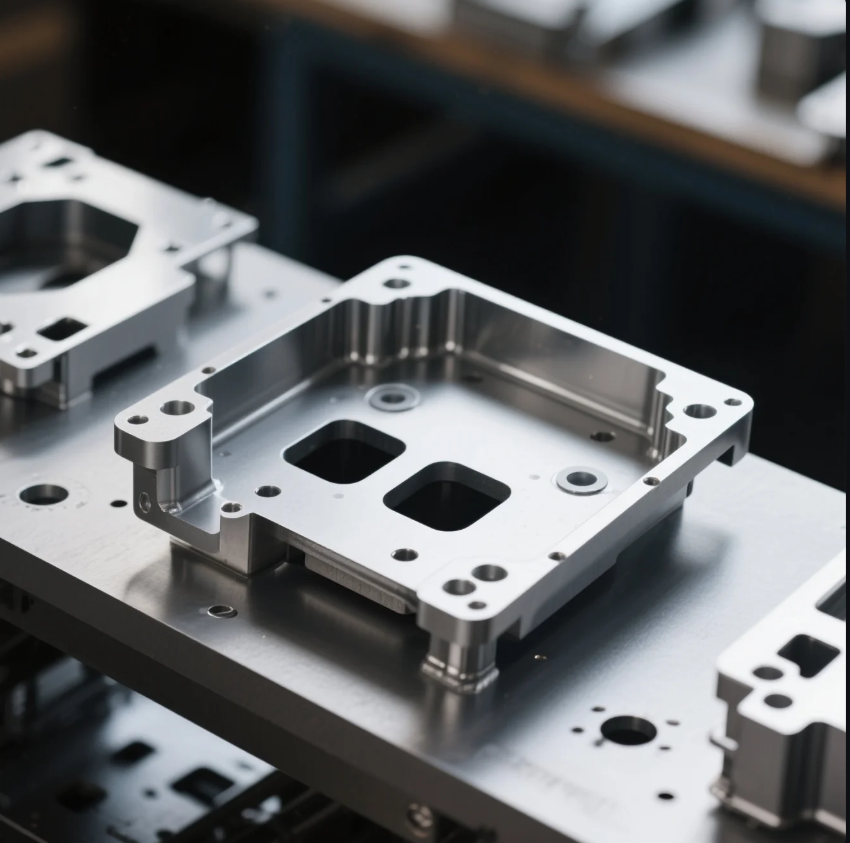

What is the cost of custom sheet metal parts?

Many buyers are unsure how much they should pay for custom sheet metal parts.

The cost of custom sheet metal parts depends on material, thickness, process type, quantity, finish, and tolerance level.

Understanding these factors helps avoid overpaying or underestimating your project budget. Let’s break it down.

How much does it cost to fabricate metal parts?

Buyers often ask for a simple price, but fabrication pricing is multi-layered.

Fabricating metal parts can cost from \$0.50 to \$50+ per piece depending on material, complexity, and quantity.

At Prime, we calculate cost based on material type, cutting and forming time, labor, tooling, and surface finish. High-volume orders lower unit cost. For example, a simple stamping part may cost \$0.80 in bulk, while a CNC-machined, coated enclosure may exceed \$20 per unit. We always provide detailed quotes, so clients understand every cost element.

Sample Pricing Guide (Estimated Per Unit)

| Part Type | Volume | Price Range |

|---|---|---|

| Simple Bracket (Stamped) | 5,000+ pcs | \$0.60 – \$1.00 |

| CNC-Milled Aluminum Plate | 100 pcs | \$8.00 – \$15.00 |

| Custom Housing (Welded) | 50 pcs | \$20.00 – \$40.00 |

| Laser-Cut Cover with Coating | 500 pcs | \$3.00 – \$6.00 |

We optimize design and processing to help clients stay within budget.

How much should sheet metal cost?

Buyers want price clarity, but “sheet metal” can mean many things.

Raw sheet metal costs from \$0.50 to \$6.00+ per kg depending on the metal type and thickness.

For finished parts, pricing depends on cutting, forming, assembly, and finishing. Mild steel is the cheapest, while stainless steel and aluminum cost more. At Prime, we stock multiple grades and thicknesses. That lets us match your specs with the most cost-effective option.

Raw Sheet Metal Cost by Material (Per Kg)

| Material | Approx. Cost (USD) | Features |

|---|---|---|

| Mild Steel | \$0.50 – \$0.80 | Cheap, strong |

| Aluminum | \$1.50 – \$2.50 | Light, corrosion-resistant |

| Stainless Steel | \$2.00 – \$3.00 | Strong, clean finish |

| Galvanized Steel | \$1.00 – \$1.80 | Rust-resistant, affordable |

We help clients select the best material for performance and pricing balance.

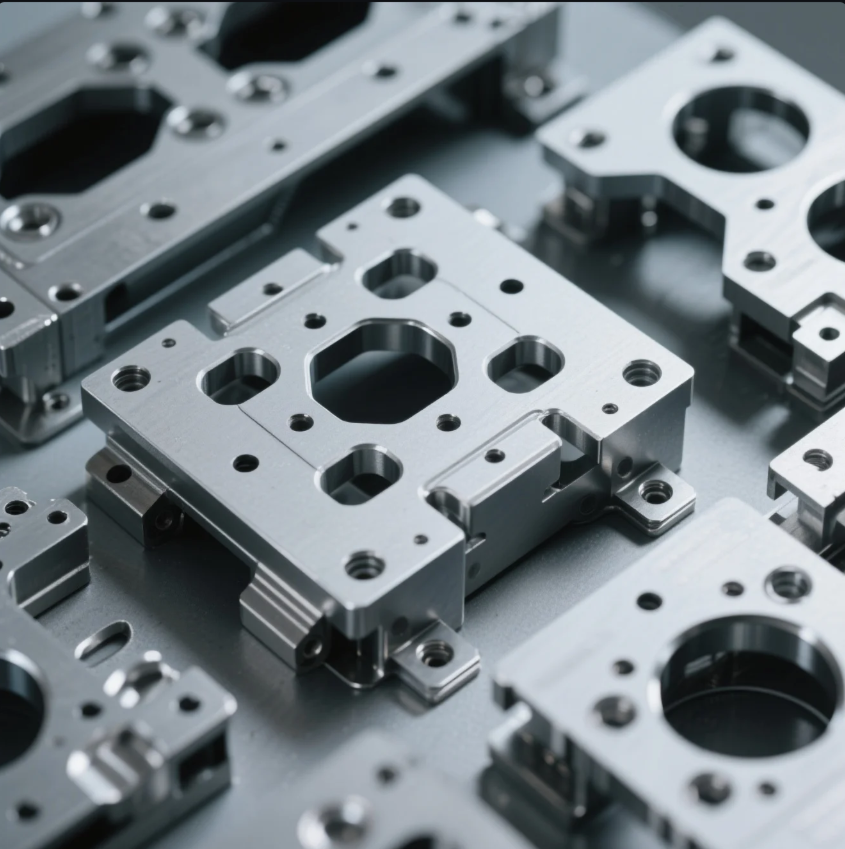

What is the fabrication process cost?

Buyers often underestimate how much labor and tooling add to the cost.

Fabrication process costs include cutting, forming, welding, coating, and assembly. Labor, machine time, and setup are major drivers.

For example, laser cutting may cost \$0.10 – \$0.50 per inch. Welding may cost \$2 – \$8 per joint. Tooling for stamping may cost thousands upfront but drops the unit cost later. At Prime, we provide flexible pricing models based on batch size, tooling ownership, and material waste control.

Breakdown of Fabrication Cost Factors

| Process | Cost Driver | Typical Cost (Est.) |

|---|---|---|

| Laser Cutting | Time, material, pattern | \$0.10 – \$0.50 per inch |

| Bending/Forming | Setup time, material thickness | \$0.50 – \$2.00 per bend |

| Welding | Joint length, type | \$2.00 – \$8.00 per joint |

| Surface Finishing | Type, coating thickness | \$0.50 – \$3.00 per part |

We advise clients on cost-saving changes like reducing bends or combining parts into single profiles.

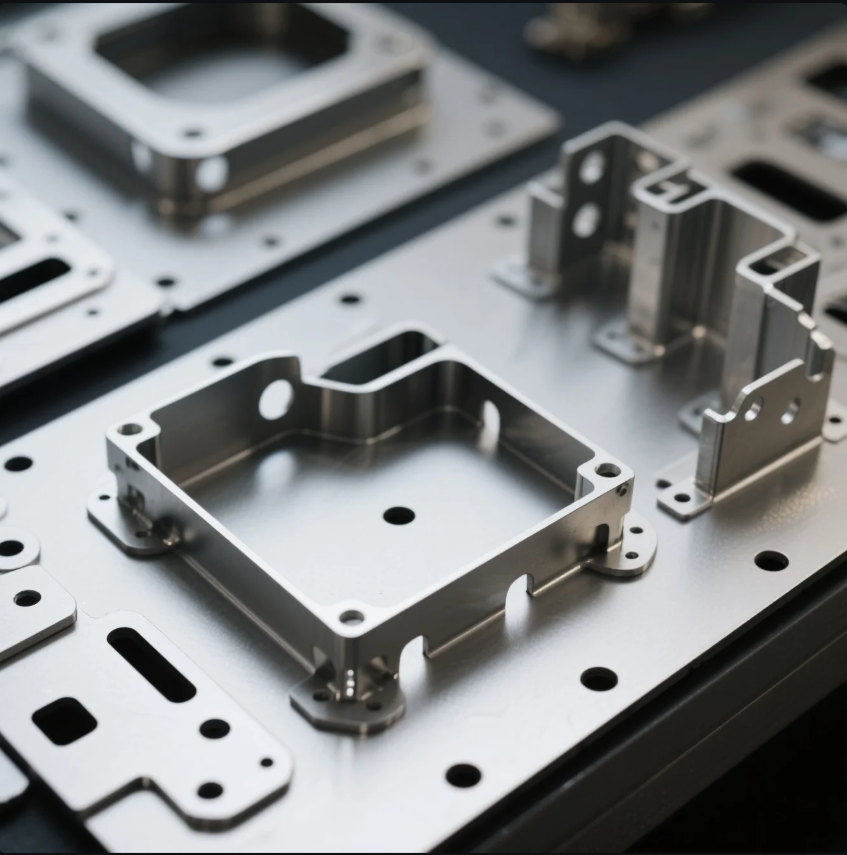

Is sheet metal forming expensive?

Forming may seem simple—but its cost depends on how it’s done.

Sheet metal forming costs vary by method. Hand forming is cheap for small runs. CNC or die-based forming is better for volume but needs tooling.

Stamping requires upfront die investment, often \$500 – \$10,000 depending on complexity. But it lowers unit price for 1,000+ parts. CNC bending is flexible and quick for lower volumes. At Prime, we offer both—helping clients choose based on order size and lifetime cost.

Forming Method Cost Comparison

| Method | Tooling Cost | Best For | Unit Cost (Est.) |

|---|---|---|---|

| Manual Bending | None | Low volume, prototypes | \$1.00 – \$5.00 |

| CNC Press Brake | Low | Medium volume, flexibility | \$0.50 – \$2.00 per bend |

| Stamping Dies | \$500 – \$10,000+ | High volume production | \$0.10 – \$1.00 per part |

We help clients transition from CNC forming to stamping once volumes justify tooling cost.

Conclusion

Custom sheet metal costs depend on material, process, volume, and finish—but smart choices can save you thousands.

Need an accurate quote for your custom metal parts? Contact Prime today. We provide transparent pricing, ISO-certified quality, and fast global delivery—backed by over 20 years of fabrication expertise.