What is the cost of motor stamping and how can you optimize it?

Motor buyers often struggle with unexpected stamping costs and complex supplier quotes.

Motor stamping costs depend on tooling, materials, precision, and volume—smart sourcing minimizes unnecessary expenses.

Let’s break down the real cost drivers and how to control them.

LOOP_START

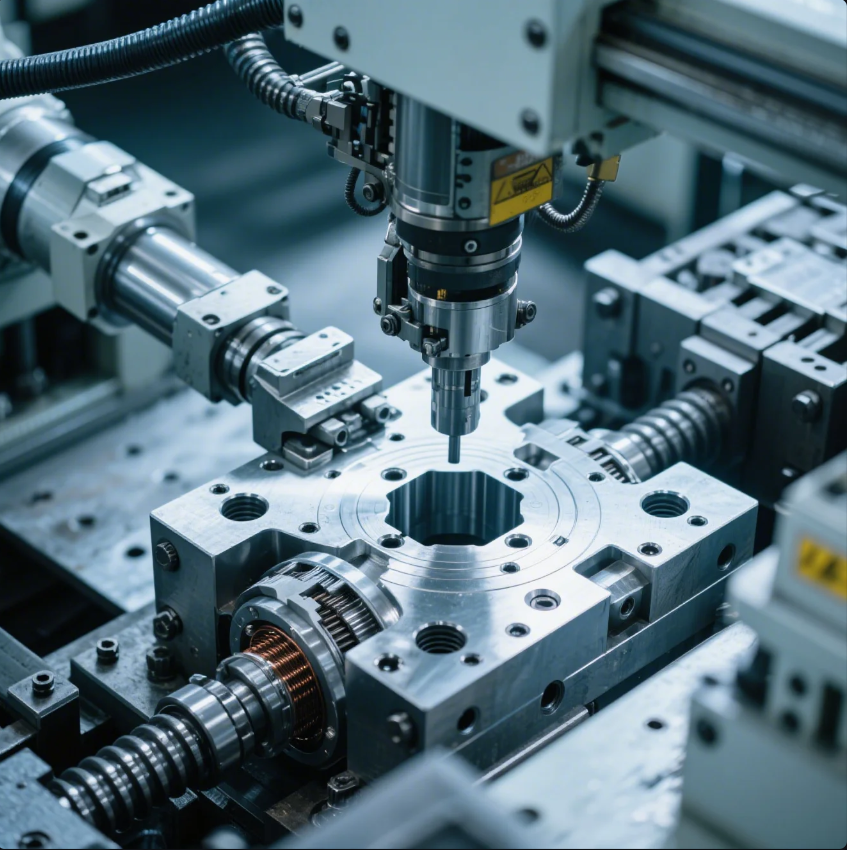

What is stamping in a motor?

Many don’t realize how essential stamped laminations are in motor performance.

Motor stamping refers to the production of thin steel laminations that make up the stator and rotor cores.

Why stamping matters in motor design

Motors rely on laminated cores to reduce eddy current losses. Each lamination is a stamped piece of electrical steel, carefully designed to balance magnetic efficiency and structural integrity.

Function and features:

| Component | Stamped Role in Motor |

|---|---|

| Stator Core | Conducts and concentrates magnetic fields |

| Rotor Core | Provides torque via electromagnetic induction |

| End Laminations | Support mechanical structure and assembly alignment |

How Prime ensures core integrity

At Prime, we use precision stamping dies to create uniform laminations with burr-free edges. Our tolerance control (±0.01 mm) ensures minimal vibration and noise, even at high RPMs. This is crucial for our European clients manufacturing high-efficiency HVAC motors and servo drives.

LOOP_END

LOOP_START

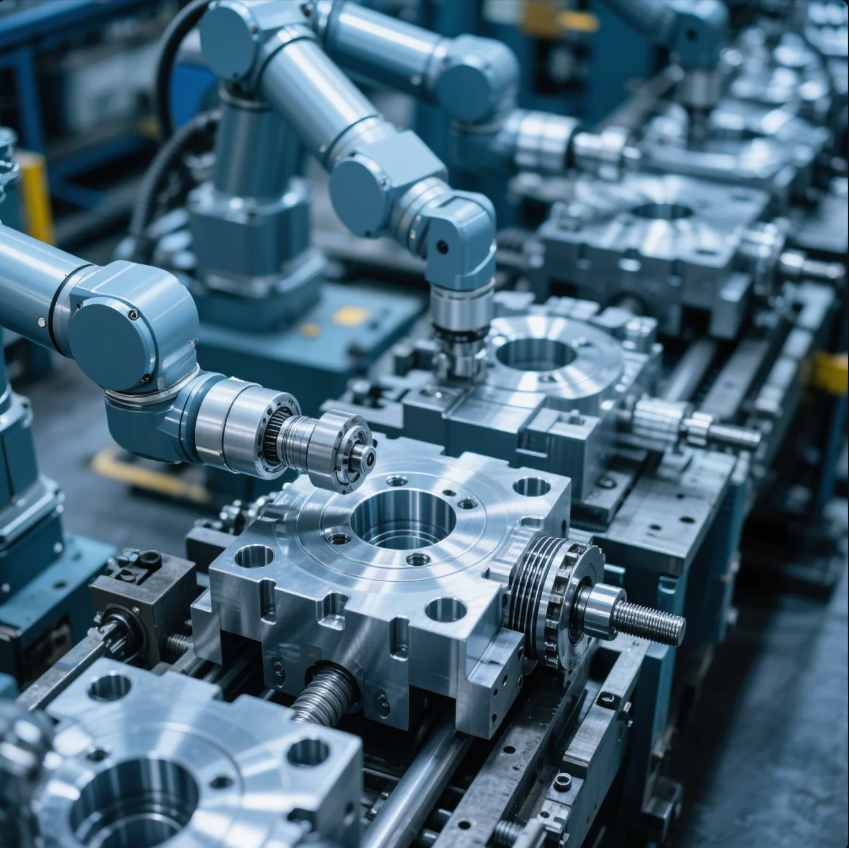

What is the process of electrical stamping?

Many engineers underestimate the precision needed for electrical steel stamping.

Electrical stamping is the process of cutting thin silicon steel sheets into motor lamination shapes using high-precision dies.

The complete electrical stamping workflow

| Step | Description |

|---|---|

| Die Design | Based on lamination geometry and motor specs |

| Sheet Material Prep | Electrical-grade steel with specific grain orientation |

| Stamping (Progressive) | Multiple features formed in one stroke using progressive dies |

| Deburring & Annealing | Removes sharp edges, relieves stress |

| Stacking & Bonding | Laminations are stacked and insulated to form the motor core |

Our process advantages at Prime

We combine progressive dies with servo-controlled presses, ensuring high throughput with minimal waste. For a recent Australian client in the renewable sector, we produced 400,000 precision-stamped laminations with a delivery lead time of just 22 days—thanks to our in-house tool shop and 10 production lines.

LOOP_END

LOOP_START

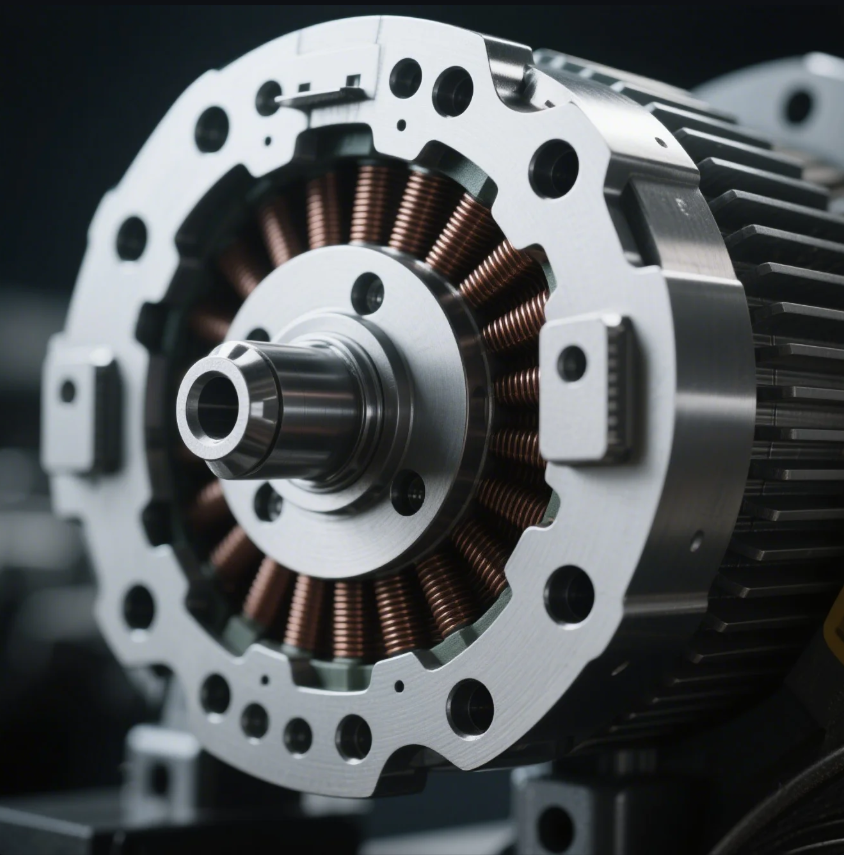

What is the cost of an induction motor?

Many buyers focus only on the price tag and overlook hidden motor component costs.

The cost of an induction motor varies from $30 to over $2,000 depending on size, quality, and core material.

What influences the total cost?

| Factor | Impact on Motor Cost |

|---|---|

| Core Stamping Quality | High-quality laminations increase efficiency and reduce losses |

| Copper vs. Aluminum Windings | Copper increases cost but improves conductivity |

| Insulation & Bearings | Higher-grade parts extend lifespan but raise cost |

| Efficiency Class (IE2/IE3) | Higher efficiency means higher initial cost |

How stamping cost fits into the picture

Stamped laminations typically account for 15%–25% of total motor cost. By working with a dedicated stamping partner, buyers can lower tooling fees, optimize batch sizes, and ensure reliable repeatability—key for projects where motor consistency matters.

At Prime, we help clients optimize lamination layouts to reduce scrap rates, and we offer bulk pricing tiers that significantly reduce per-unit cost for large orders.

LOOP_END

LOOP_START

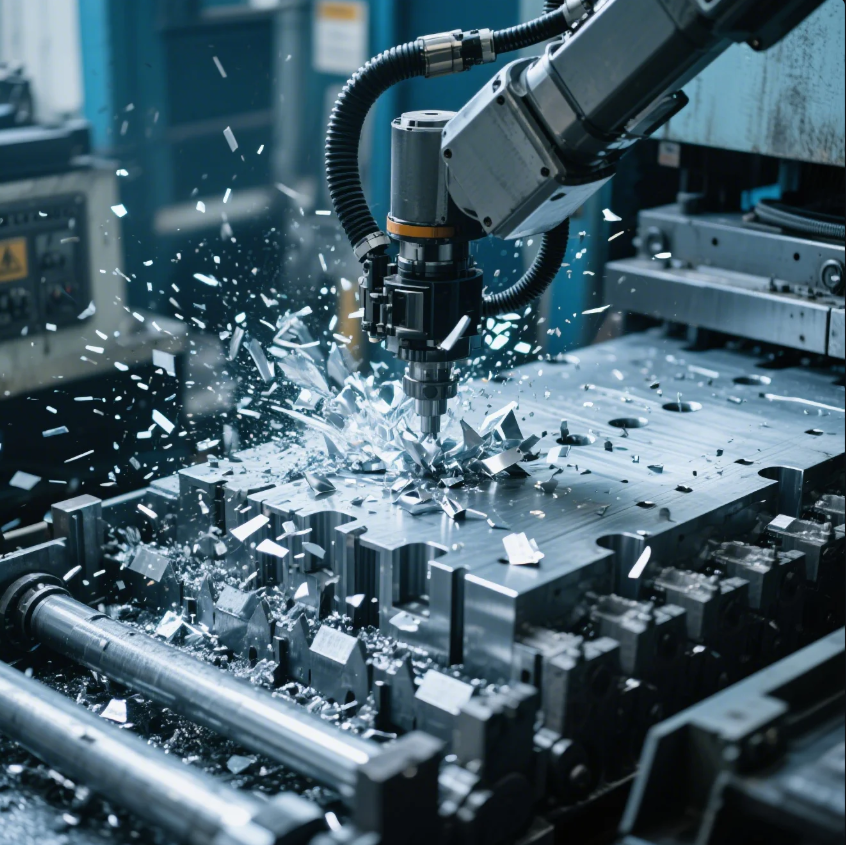

What is the process of stamping machine?

Some suppliers still rely on outdated presses, leading to lower quality and higher rejection rates.

A stamping machine uses controlled pressure to form metal sheets into desired shapes through dies.

Typical workflow in a stamping machine setup

| Stage | Function |

|---|---|

| Coil Feeding | Automatically feeds electrical steel into the machine |

| Punching | Cuts lamination shapes using high-speed dies |

| Indexing | Positions the sheet for the next punch stroke |

| Collection & Stacking | Collects finished laminations in a stacked format |

Why machine quality affects stamping cost

Poorly maintained stamping machines produce misaligned parts, leading to rework or rejection. That’s why at Prime, our servo presses with auto-lubrication and real-time monitoring deliver parts that are within spec every time.

For a U.S. client building industrial pump motors, this meant zero part failure over 12 months—saving both time and maintenance costs.

LOOP_END

Conclusion

Motor stamping cost is driven by precision, material, and volume—optimize all three to reduce waste and improve ROI.

Need to reduce your motor core production costs? Contact Prime today for free expert consultation, competitive quotes, and fast-turnaround lamination stamping—trusted by global OEMs for quality, speed, and reliability.