What Does E7018 Mean?

Welding rod numbers look confusing—but understanding them helps avoid wrong rod selection and weak welds.

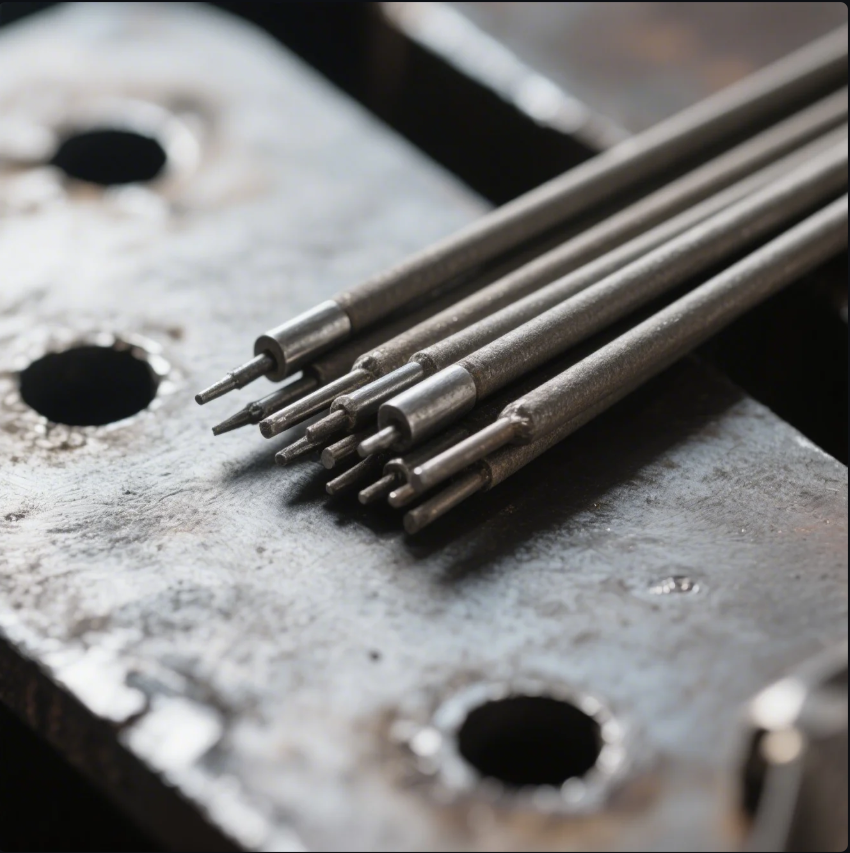

E7018 is a low-hydrogen electrode for welding carbon and low-alloy steel, designed for strength and smooth arc performance.

Let’s break down exactly what each number means—and why this rod doesn’t work on aluminum.

Can I use 7018 on aluminum?

No—trying 7018 on aluminum is like using the wrong key in a lock.

You cannot use 7018 on aluminum—it’s made exclusively for steel.

Why 7018 fails on aluminum

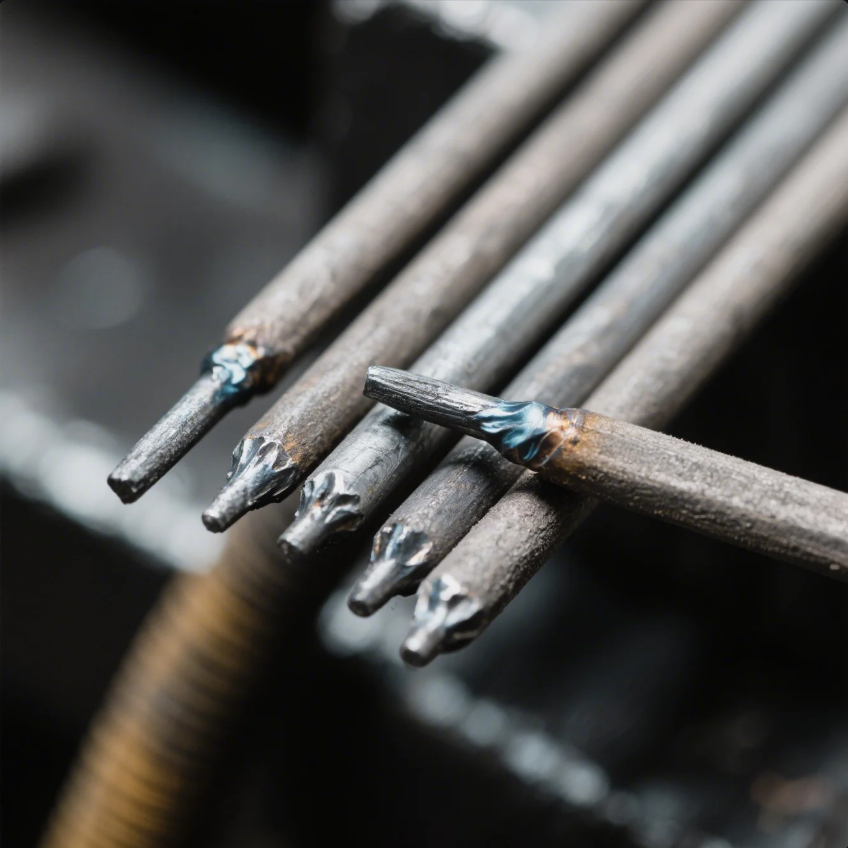

7018 electrodes contain an iron powder low-hydrogen flux coating, which:

- Matches carbon steel chemistry

- Requires much lower melting temperatures than aluminum

- Creates no metallurgical bond with aluminum

I’ve seen customers try welding aluminum with 7018—it results in porous, brittle, or nonexistent welds.

Table: 7018 Compatibility by Metal

| Metal Type | 7018 Weldable? | Notes |

|---|---|---|

| Mild Steel | ✅ Yes | Ideal application |

| Low-Alloy Steel | ✅ Yes | Strong joints |

| Stainless Steel | ❌ No | Needs stainless electrode |

| Aluminum | ❌ No | Requires aluminum-specific rod |

At Prime, we strictly reserve 7018 for steel. For aluminum, we use MIG with spool gun or TIG with argon shielding for clean, precise welds.

What is the best amperage for 7018 welding rod?

Get the amperage wrong—and even 7018 rods won’t perform well.

Best amperage for a 7018 rod depends on rod size, but usually ranges between 90–210 amps.

Amperage by rod diameter

Here’s the basic rule I teach clients:

- Higher diameter = higher amperage

- Thinner material = lower amperage

Table: 7018 Amperage Guide

| Rod Diameter | Recommended Amperage | Best For |

|---|---|---|

| 3/32" (2.4mm) | 75–110A | Light steel (sheet, angle) |

| 1/8" (3.2mm) | 110–150A | Most general applications |

| 5/32" (4.0mm) | 150–210A | Heavy plate, thick pipe |

At Prime, we test weld settings on scrap before full production and use calibrated digital machines to ensure consistent amperage output.

What do the numbers on a 7018 rod mean?

The code isn’t random—each digit tells you how the rod performs.

7018 means: 70 = tensile strength (70,000 psi), 1 = all position, 8 = low-hydrogen flux.

E7018 decoded

Let’s break it down:

- E = Electrode

- 70 = Tensile strength (70,000 PSI)

- 1 = All-position welding (flat, vertical, overhead)

- 8 = Flux type (low-hydrogen, iron powder coating)

This rod produces ductile, strong, and smooth welds, making it ideal for structural work.

Table: 7018 Code Breakdown

| Digit(s) | Meaning |

|---|---|

| E | Electrode for arc welding |

| 70 | 70,000 PSI tensile strength |

| 1 | All-position capable |

| 8 | Iron powder, low-hydrogen |

We use 7018 rods at Prime for certified structural steel components, including brackets, frames, and industrial supports.

Do you weld 7018 AC or DC?

Choose the wrong polarity—and your arc won’t even start properly.

7018 electrodes can be used with both AC and DCEP (DC+) current, but DC+ gives better performance.

AC vs. DC for 7018

- DC+ (reverse polarity): Smoother arc, deeper penetration

- AC: Acceptable for older or transformer machines

- DC-: Not recommended—unstable arc and poor weld quality

Most modern inverter welders default to DCEP, and that’s what we use at Prime for cleaner starts, better fusion, and reduced spatter.

Table: Current Type for 7018

| Current Type | Usability | Notes |

|---|---|---|

| DC+ (DCEP) | ✅ Best | Smoothest arc, best results |

| AC | ✅ Acceptable | Slightly rougher arc |

| DC- (DCEN) | ❌ Not ideal | Inconsistent, poor penetration |

We always advise clients setting up in-house weld stations to test 7018 rods on both AC and DC, then stick with the cleanest result for their material and machine.

Conclusion

7018 rods are strong, versatile, and reliable—for steel only. Aluminum needs a different approach.

Want expert help selecting the right welding process or material?

Contact Prime now for certified welding services, CNC prepped parts, and full process support.

We serve global clients with ISO-approved quality, quick turnaround, and free consultation.

Send us your inquiry and weld smarter today.