What Is the Enemy of Aluminum?

Aluminum is lightweight and corrosion-resistant — until it meets its worst enemies.

In 2025, understanding what metals and conditions degrade aluminum is critical for product life, safety, and design efficiency. Aluminum reacts poorly with certain materials and environments, which can lead to rapid corrosion, failure, or discoloration.

This guide explores the most harmful metals to aluminum, how reactions occur, and what to avoid in both indoor and outdoor applications.

What Metals Don’t Interact with Aluminum?

Some metals can safely contact aluminum with little or no risk of galvanic reaction.

Compatible metals include anodized aluminum, stainless steel (with insulation), zinc (in specific cases), and magnesium.

Low-Risk Metals When Used with Aluminum

| Metal | Compatibility | Notes |

|---|---|---|

| Anodized Aluminum | Excellent | Same material, best choice |

| 304/316 Stainless Steel | Good | Needs isolation in wet areas |

| Zinc (coated fasteners) | Moderate | Avoid long-term exposure to moisture |

| Magnesium | Good | Similar potential, often used in alloys |

Prime offers ISO-certified aluminum-compatible fasteners and mounting hardware that prevents surface wear, corrosion, and bonding failures in industrial environments.

What Does Aluminum React Badly With?

Aluminum reacts most severely with metals that are far from it on the galvanic series and in the presence of electrolytes (like water).

Problem metals include copper, brass, and galvanized steel — especially when aluminum is exposed to moisture, salt, or acidic environments.

Common Problem Scenarios

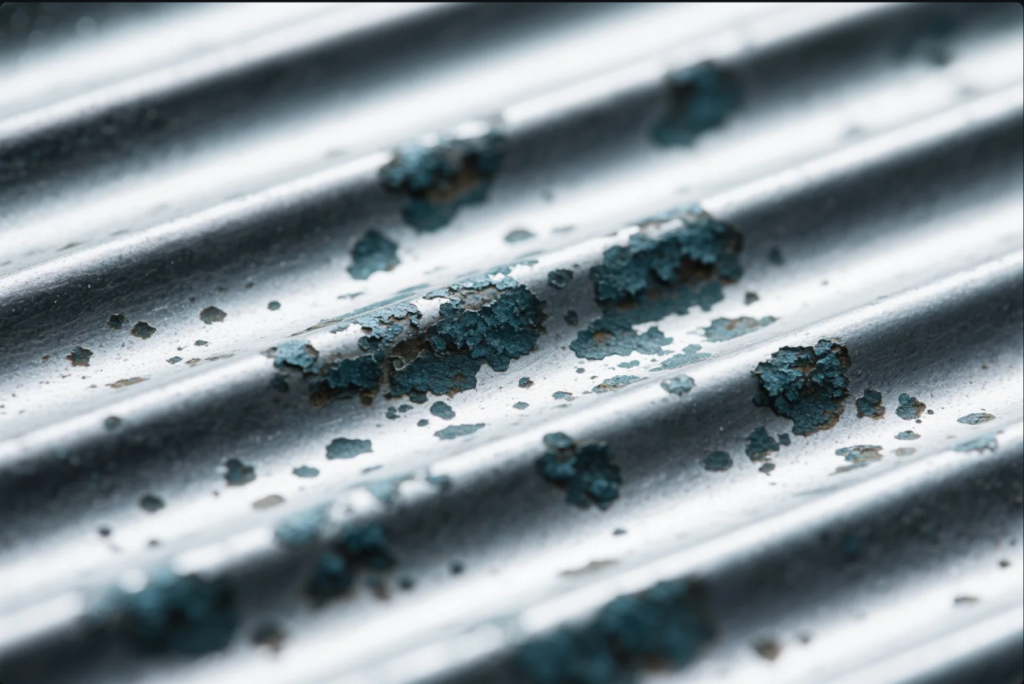

- Brass screws in aluminum window frames – Results in green and white corrosion.

- Copper plumbing touching aluminum brackets – Rapid pitting and weakening.

- Steel bolts in aluminum marine structures – Severe rust and surface damage.

For weather-exposed or coastal applications, Prime supplies marine-grade 316 stainless steel fasteners with insulating washers, ideal for joining aluminum to other metals safely.

What Metal Destroys Aluminum?

Copper is aluminum’s worst enemy — it accelerates corrosion and structural breakdown when in contact with moisture.

Copper creates a strong galvanic reaction, causing the aluminum to corrode rapidly while the copper remains intact.

Corrosion Severity by Metal Contact

| Contact Metal | Aluminum Corrosion Rate | Risk Level |

|---|---|---|

| Copper | Very High | Severe |

| Brass | High | High |

| Carbon Steel | Moderate to High | Moderate |

| Stainless Steel | Low | Low |

| Zinc | Medium (environmental) | Variable |

To avoid damage, never let copper pipes, wires, or fasteners touch aluminum directly. Prime engineers help OEM clients redesign mixed-metal joints using isolation grommets, nylon spacers, and custom coatings.

What Does Aluminum Not React Well With?

Beyond metals, aluminum also reacts poorly with certain chemicals and moisture-related conditions.

Aluminum does not react well with alkaline solutions, saltwater, acidic cleaners, and certain untreated paints or coatings.

Environmental Enemies of Aluminum

| Chemical/Condition | Effect on Aluminum |

|---|---|

| Saltwater | Causes pitting |

| Alkaline Detergents | Breaks oxide layer |

| Acid Rain | Etching, discoloration |

| Chlorinated Solvents | Stress cracking |

| Untreated Steel Paint | Traps moisture, corrodes |

To maintain aluminum’s performance, Prime provides anodized or powder-coated surfaces, sealed fastener kits, and custom part packaging that prevent oxidation during transport and use.

How to Prevent Aluminum Corrosion in Mixed-Metal Assemblies

What is the enemy of aluminum? Designing aluminum into a multi-metal assembly? You can prevent damage using proper fastener materials and contact isolation.

Prime’s Proven Solutions

-

Use Isolators

- Nylon or rubber washers, bushings, sleeves.

-

Apply Anti-Galvanic Coatings

- Zinc-nickel plating, e-coating, or polymer dips.

-

Use Compatible Fasteners

- 316 stainless steel, anodized aluminum, nickel-coated brass.

-

Seal or Shield Joints

- RTV silicone, dielectric grease, epoxy barriers.

-

Design for Drainage and Ventilation

- Avoid trapped water in joints or crevices.

Prime’s team helps clients choose the right fastener and joint design for aluminum machinery, rail systems, solar frames, and marine enclosures — all backed by ISO certifications and rapid export delivery.

FAQs

Q1: Why does aluminum corrode next to copper?

A1: Copper is much more noble. When moisture is present, aluminum becomes the sacrificial metal and corrodes quickly.

Q2: Are galvanized screws OK for aluminum roofs?

A2: Not long term. Zinc coating breaks down and accelerates white rust formation on aluminum. Use stainless alternatives.

Q3: How do I know if a screw is safe for aluminum?

A3: Check the galvanic series. Choose fasteners close to aluminum or use coated stainless steel with isolators.

Q4: What’s better: brass or stainless steel screws for aluminum windows?

A4: Stainless steel. Brass reacts more with aluminum, especially outdoors.

Q5: Can Prime help me customize fastener packaging and coatings?

A5: Yes. We offer custom-labeled screw kits, anti-corrosion coatings, and OEM-specific packaging for bulk buyers.

Conclusion

The real enemy of aluminum is improper metal pairing and poor environmental design. Avoid copper, galvanized steel, and uncoated brass in mixed-metal assemblies. Use stainless steel or anodized aluminum fasteners — and always isolate dissimilar materials. For expert advice and durable fasteners engineered for aluminum, visit Prime or email [email protected].