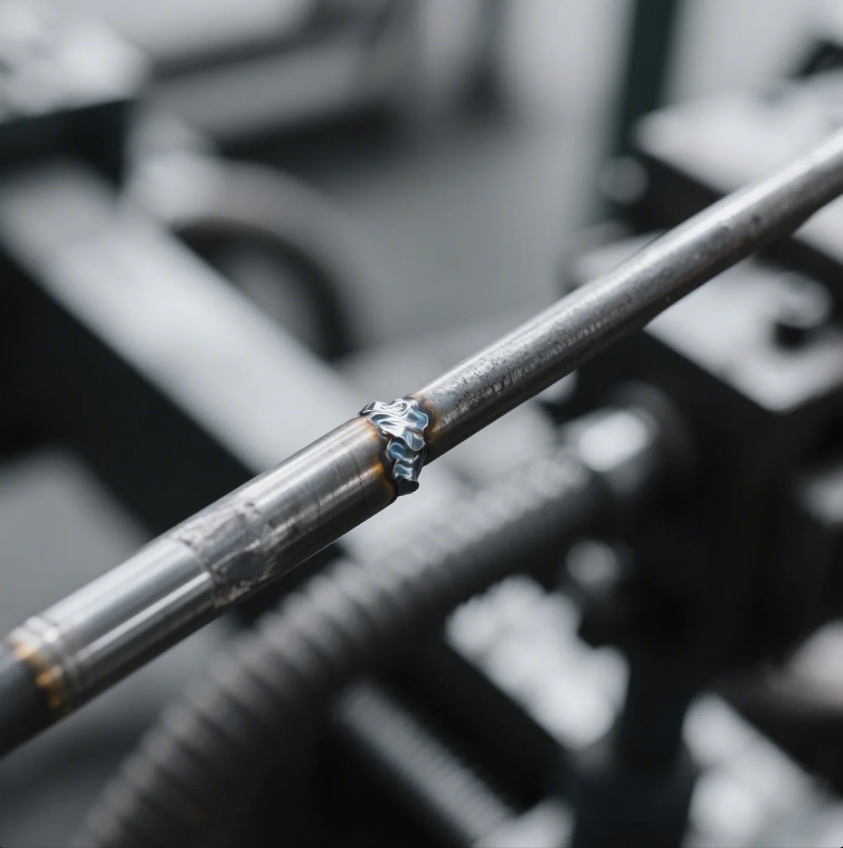

What is the hardest rod to weld with?

Some rods test your technique more than your machine.

E6010 is widely considered the hardest welding rod to use—it has a fast-freeze puddle, unstable arc, and demands precise control.

Let’s see why it’s challenging, how it compares to others, and what welders need to master it.

What is the most difficult thing to weld?

Some metals just don’t like being joined.

Aluminum and thin stainless steel are among the most difficult materials to weld due to their low melting points, high conductivity, and tendency to distort or crack.

One Prime client in the food industry needed 1 mm stainless TIG welds with no discoloration. It took our most skilled welders, tightly controlled amps, and multiple chill blocks to get it right.

Why these materials are difficult

| Material | Challenge |

|---|---|

| Aluminum | Oxide layer, fast heat transfer |

| Stainless steel | Warps easily, sensitization risk |

| Titanium | Reacts to air, needs full shielding |

| Cast iron | Cracks under tension, preheat required |

At Prime, we provide custom welding services with alloy-specific strategies to handle even the toughest joints.

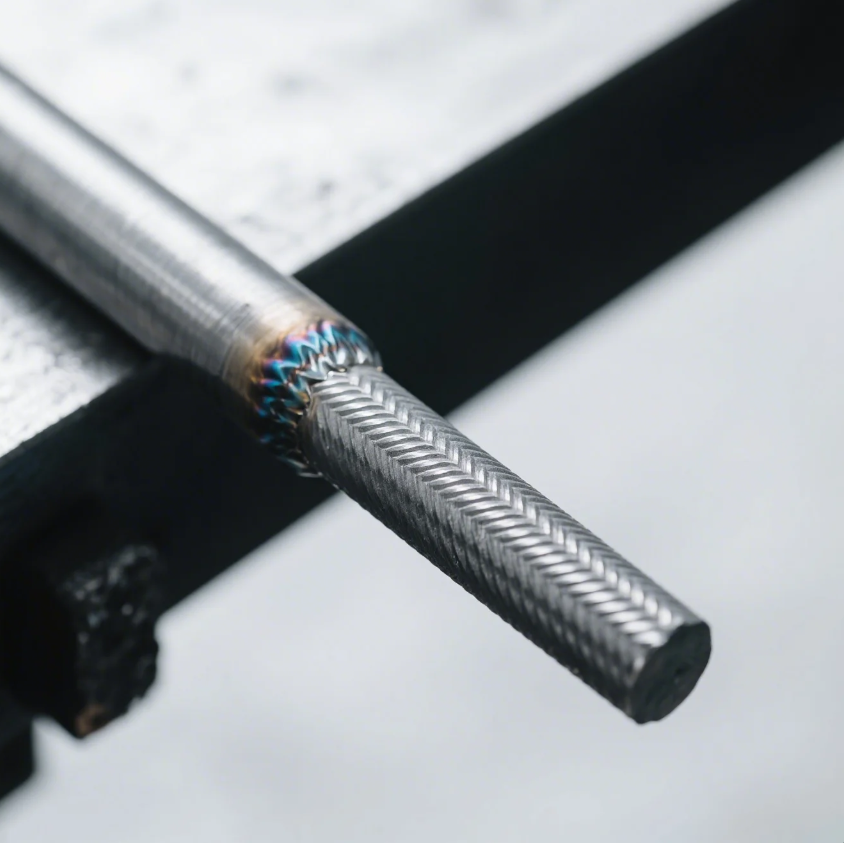

Which welding rod is strongest?

Not all strength is created equal.

E7018 is considered one of the strongest welding rods, offering high tensile strength, ductility, and excellent impact resistance.

One client building offshore structural supports used only E7018 for critical welds. Its low hydrogen content reduced cracking, and every joint passed X-ray inspection.

Strength comparison of common rods

| Rod Type | Tensile Strength | Hydrogen Control | Use Case |

|---|---|---|---|

| E7018 | ≥ 70,000 psi | Low | Structural steel, code welding |

| E6011 | ~60,000 psi | Medium | Repairs, field welding |

| E6013 | ~60,000 psi | Standard | Sheet metal, light fab |

Prime supplies ISO-certified low-hydrogen rods like E7018 with full testing reports for code-critical projects.

Which is harder 6011 or 7018?

It depends on the skill—and the situation.

E6011 is harder for beginners due to its aggressive arc, whip technique, and tendency to spatter. E7018 is smoother but requires more prep and proper storage.

During training with a U.S. fabricator, we found entry-level welders struggled more with 6011. It took time to master the motion. But once they did, they appreciated its versatility on dirty metal.

6011 vs. 7018 Comparison

| Feature | E6011 | E7018 |

|---|---|---|

| Arc Control | Fast freeze, whip technique | Smooth, consistent |

| Surface Prep | Minimal | Requires clean metal |

| Weld Appearance | Rougher finish | Clean, uniform beads |

| Storage Needs | No rod oven needed | Must be kept dry |

Prime helps clients pair the right rod with their use case—whether it’s on-site repair or high-spec factory welding.

What is the easiest rod to weld with?

Need a rod that forgives mistakes?

E6013 is considered one of the easiest welding rods to use—it offers a stable arc, low spatter, and easy slag removal, even for beginners.

One training center we worked with in Southeast Asia chose 6013s for all new welders. Within a few hours, most could run straight beads on flat plate with minimal coaching.

Why E6013 is beginner-friendly

- Soft arc is easy to control

- Works well on AC or DC

- Smooth bead profile with low spatter

- Minimal post-weld cleanup

| Rod Type | Ease of Use | Best For |

|---|---|---|

| E6013 | Very easy | Training, general fabrication |

| E7014 | Easy | Clean steel, decorative welds |

| E6011 | Moderate-hard | Field repair, vertical work |

Prime includes E6013 in our starter welding kits and provides full guides for training centers, vocational schools, and industrial customers.

Conclusion

E6010 is the hardest rod to master—but E7018 delivers the strength, and E6013 makes the best starting point for new welders.

Looking for the right rod for your project or training program? Contact Prime today through our website. We offer ISO-certified welding rods, expert advice, and fast global delivery tailored to your job’s unique challenges.