What is the lead time for custom plastic parts?

Many buyers struggle with delayed deliveries and vague timelines from suppliers.

Lead time for custom plastic parts typically ranges from 7 to 30 days, depending on part complexity, tooling, and order volume.

Fast lead times help you launch on time, restock faster, and stay ahead of the competition.

Let’s explore how long each step takes—and how Prime keeps projects on schedule.

What is the lead time for custom PCB?

Buyers sometimes mix up plastic part lead times with PCB production.

Custom PCB lead times are usually 5–14 days. However, plastic parts often take longer due to mold fabrication.

Plastic part timelines depend more on design and tooling than PCB etching or assembly.

PCB vs. Plastic Part Lead Times

| Product Type | Typical Lead Time | Influencing Factor |

|---|---|---|

| PCB (Standard) | 5–10 days | Layer count, finish |

| PCB (Assembled) | 10–20 days | Component sourcing |

| Plastic Part | 15–30 days | Mold design, part size |

At Prime, we offer 7–15 day lead times for simple molded plastic parts and provide real-time progress updates.

What is the manufacturer standard lead time?

Many buyers receive unclear replies when they ask about timing.

Standard lead time varies by factory, but for plastic parts, it usually ranges between 15 and 30 business days.

This includes mold making (if needed), material prep, production, and quality checks.

Lead Time Breakdown for Plastic Parts

| Step | Time Needed |

|---|---|

| Mold design & build | 7–15 days |

| Sample approval | 2–5 days |

| Production | 3–10 days |

| Inspection & packing | 1–2 days |

Prime supports shorter lead times through in-house tooling, 10 production lines, and parallel processing systems.

What is the plasticization time?

Plasticization is a technical step, but clients still ask how it affects speed.

Plasticization time refers to how long it takes to melt and mix the plastic resin in an injection molding machine.

It directly impacts molding cycle time and overall part output speed.

Plasticization Time Details

| Factor | Impact on Time |

|---|---|

| Resin type | Higher temp = slower |

| Screw speed | Faster rotation = shorter time |

| Shot size | Larger = longer melt time |

At Prime, we optimize plasticization by selecting the right machines and temperature profiles. This ensures stable output and faster part cycles.

How do you get a plastic part manufactured?

First-time buyers often ask what steps are needed to get a part made.

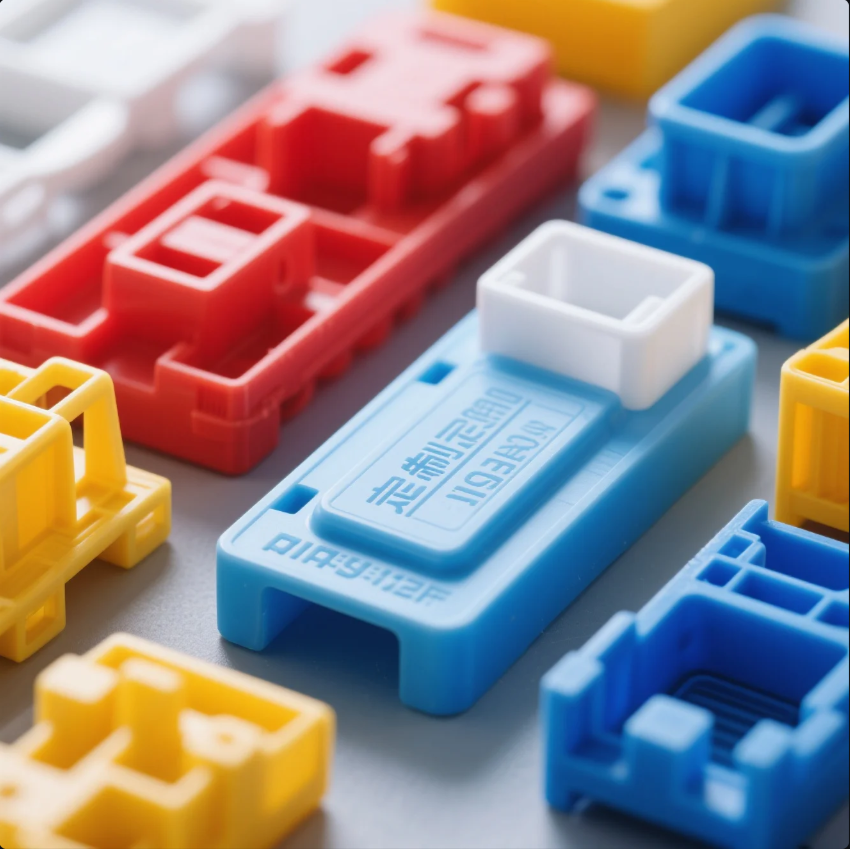

To manufacture a plastic part, you need a design file, a suitable plastic material, and a molding or machining process.

Working with an experienced partner saves time and reduces errors.

Steps to Manufacture a Plastic Part

- Share a 3D CAD or sample

- Select the material (ABS, Nylon, PC, etc.)

- Approve tooling (mold or fixture)

- Run trial sample and confirm

- Start mass production

Prime offers end-to-end service, from design support to global shipping. With ISO-certified systems and short lead times, we help clients avoid costly delays and get their products to market faster.

Conclusion

Lead time for plastic parts depends on design, tooling, and order size. With the right partner, you can get parts in as fast as 7 days.

Looking for a fast-turnaround plastic part manufacturer with clear timelines and global delivery? Contact Prime now for a free quote and lead time estimate. We combine precision, speed, and ISO quality to keep your business moving.