What is the machine called that bends metal?

Shaping metal without breaking it requires precision—and the right machine.

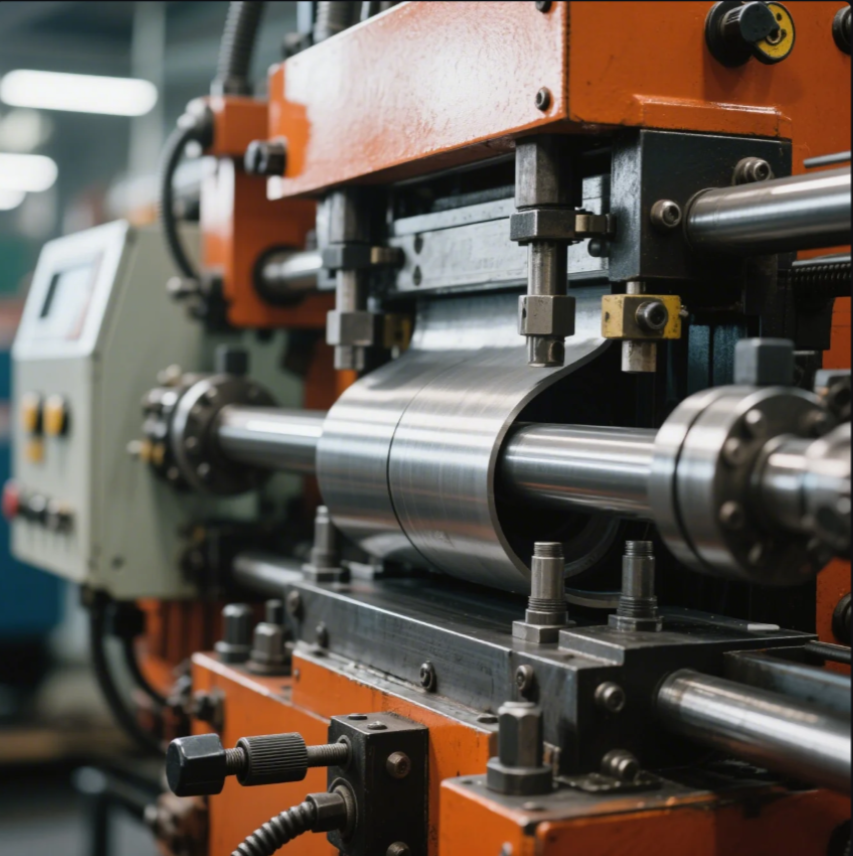

The machine used to bend metal is called a press brake. It applies force through a punch and die to create precise bends in sheet metal.

At Prime, we use CNC press brakes to create accurate, repeatable bends in aluminum, steel, and stainless components for enclosures, brackets, and frames.

What is a metal bending machine called?

From simple angles to complex forms—it all starts with the right name.

A metal bending machine is called a press brake. It can be hydraulic, mechanical, or electric depending on the force and accuracy required.

At Prime, we use hydraulic and CNC-controlled press brakes to bend materials from 0.5 mm to 10 mm thick with tight tolerances.

Types of Metal Bending Machines

| Machine Type | Key Feature |

|---|---|

| Manual Press Brake | Hand-operated, for light work |

| Hydraulic Press Brake | Strong and widely used in industry |

| CNC Press Brake | Automated, high precision |

| Panel Bender | Best for large sheet panels |

Each machine fits different part sizes, volumes, and bend complexities.

What process is used to bend metal?

Bending may look simple—but it’s all about controlled deformation.

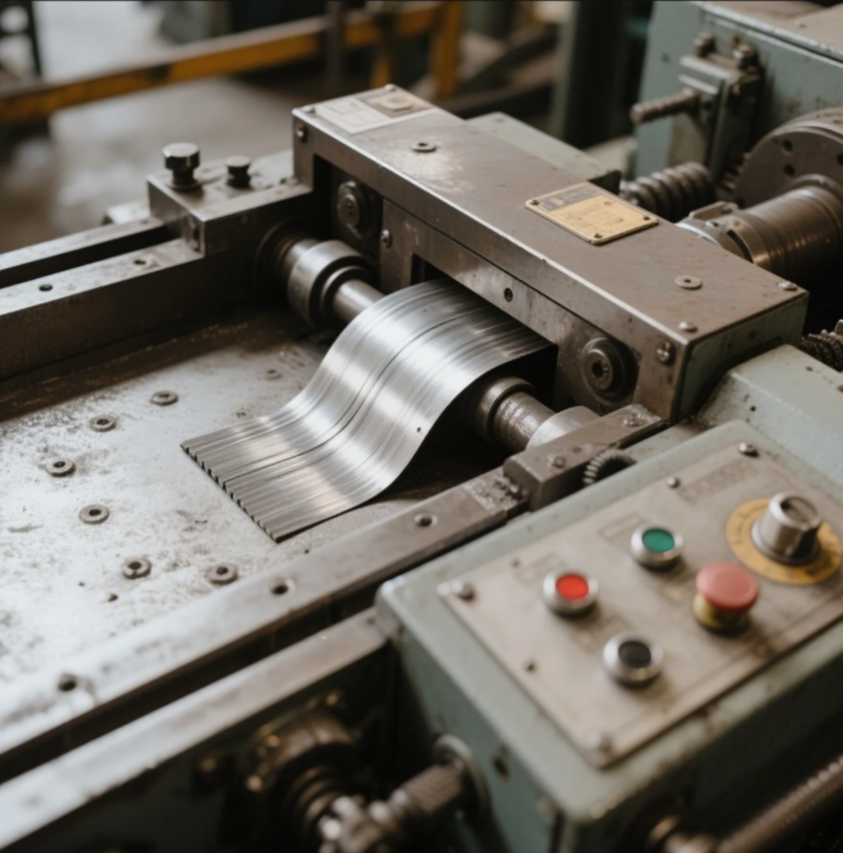

Metal is bent using the press brake forming process, where a punch pushes the sheet metal into a matching die.

At Prime, we use air bending and bottom bending techniques, depending on the radius, angle, and thickness required.

Sheet Metal Bending Methods

| Process Type | Description |

|---|---|

| Air Bending | Punch doesn’t fully close the die |

| Bottom Bending | Sheet is pressed into the die base |

| Coining | High-pressure precision forming |

| Roll Bending | Used for large curves or cylinders |

We choose the method based on part geometry, material, and tolerance needs.

Which device is used to bend metal sheets?

Flat sheets need force—and control—to become functional parts.

A sheet metal press brake is the device used to bend metal sheets into angles or complex shapes.

At Prime, we rely on programmable CNC press brakes for consistent bends across thousands of parts, reducing variation and rework.

Press Brake Bending Setup

| Component | Function |

|---|---|

| Punch | Applies force to shape the metal |

| Die | Supports and forms the bend angle |

| Back Gauge | Positions sheet for repeatable accuracy |

| Control System | Stores bend programs and sequencing |

We simulate each bend in software before production to prevent cracking or misalignment.

What is the name of the machine that cuts metal?

Before bending, every metal part starts with a clean cut.

The machine that cuts metal is commonly called a shear, laser cutter, or plasma cutter—depending on the method.

At Prime, we use fiber laser cutters, CNC turret punches, and hydraulic shears for different cutting needs before bending.

Metal Cutting Machines Overview

| Machine Type | Best Use |

|---|---|

| Guillotine Shear | Straight cuts in sheet stock |

| CNC Laser Cutter | Complex, precise shapes |

| Plasma Cutter | Thick steel, fast but less accurate |

| Waterjet Cutter | Cold cutting, no heat distortion |

We pair cutting and bending machines to streamline workflow and reduce handling time.

Conclusion

The machine that bends metal is called a press brake—used in nearly every precision sheet metal process.

Need expert bending and cutting for your parts? Prime delivers CNC bending, ISO-certified forming, and laser-cut blank preparation to ensure accuracy from flat pattern to final form. Contact us today for a detailed quote.