What Is the Meaning of Custom Fabrication?

Every product starts with a need — but off-the-shelf solutions don’t always fit.

Custom fabrication means creating a part or product from scratch, based on exact customer specifications. It involves cutting, bending, welding, and assembling to bring unique ideas to life.

Let’s explore what this really means — with simple examples, definitions, and real-world uses.

What Is Custom Fabrication?

Standard parts don’t always work. That’s where custom fabrication comes in.

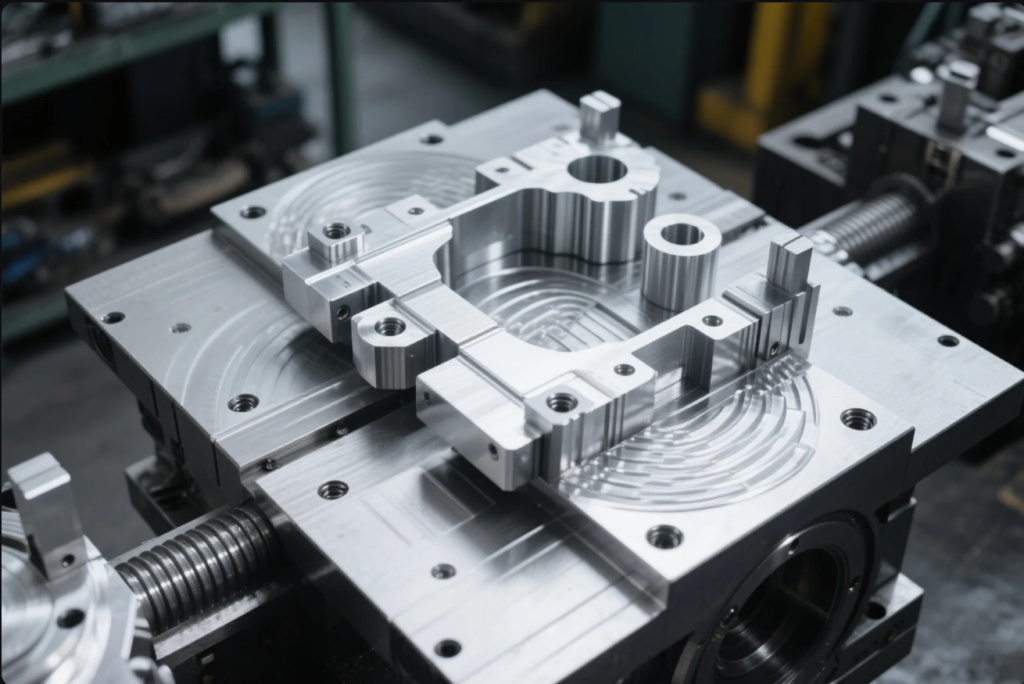

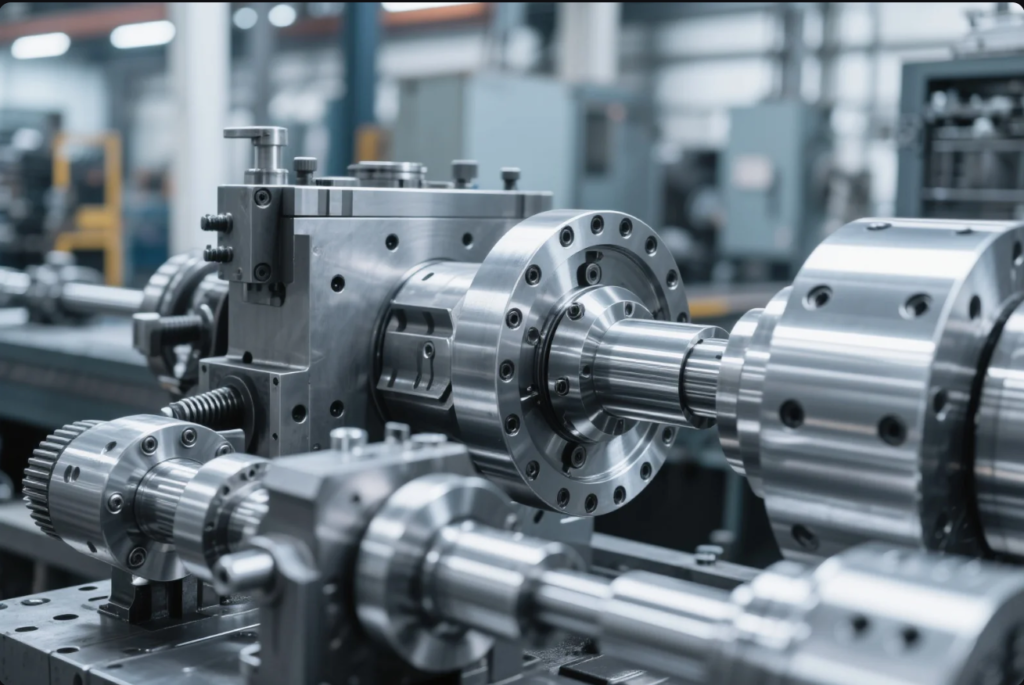

Custom fabrication is the process of building metal or plastic components based on client-provided dimensions, drawings, or functional needs.

Key Features of Custom Fabrication

- Starts from raw sheet, pipe, or billet

- Uses CNC cutting, forming, welding, and machining

- Made for specific industries, sizes, or uses

| Step | Process | Outcome |

|---|---|---|

| Cutting | CNC laser, plasma, waterjet | Base shapes, clean edges |

| Bending/Forming | Press brake or rollers | Brackets, angles, curves |

| Welding/Joining | MIG/TIG/spot weld | Frames, enclosures |

| Surface Finish | Powder coating, polishing | Ready-to-use components |

At Prime, we’ve provided custom fabrication services since 1993 for clients in construction, machinery, electronics, and automotive.

What Is the Fabrication of Meaning?

In a technical or industrial context, fabrication means manufacturing — not fiction.

The fabrication of something refers to the act of building, shaping, or creating a product through industrial processes.

In manufacturing, “fabrication” usually means:

- Building something tangible

- Often made of metal, plastic, or composites

- Shaped through mechanical force, heat, or cutting

This contrasts with the word "fabrication" used in a different context (like telling a lie). In this article, we’re strictly talking about metalworking and part production.

What Is the Meaning of Fabrication?

Simply put: fabrication is the process of constructing something from raw material into a functional part or assembly.

It’s a core concept in manufacturing and engineering.

Why Fabrication Matters

Without fabrication, engineers and designers would have no way to:

- Turn digital files into physical products

- Create test parts for R\&D

- Build machines, buildings, and devices

| Fabrication Method | Common Output | Application |

|---|---|---|

| CNC Machining | Precision brackets, housings | Aerospace, robotics, tooling |

| Sheet Metal Forming | Panels, cases, covers | Electronics, HVAC, appliances |

| Tube Welding | Frames, rails, enclosures | Construction, industrial carts |

Fabrication allows every industry to scale — from a prototype to production.

What Is an Example of Fabrication?

Let’s make it practical.

Example: A client needs a stainless steel cabinet to protect electronics outdoors.

Here’s what custom fabrication looks like:

- Client provides rough size and function

- Prime engineers design the layout with hinges, mounts, and vents

- We laser cut stainless sheets

- Then we bend, weld, and polish the shell

- Surface finishing with anti-corrosion powder coat

- Final QC, then packing for shipment

This is one of thousands of real examples — others include:

- Machine guards

- Industrial racks

- Automotive panels

- Custom signage or frames

We help every customer turn an idea into a solid, lasting part.

FAQs

Q1: What materials can you fabricate?

We work with steel, stainless, aluminum, copper, and even plastics.

Q2: What industries use custom fabrication most?

Construction, energy, medical, automotive, and electronics.

Q3: Can I order one-off or low-volume parts?

Yes. We support both prototype and bulk production.

Q4: What standards do you meet?

We are ISO-certified and follow DIN, ASTM, and client-specific tolerances.

Q5: Do you provide surface finishes?

Yes. Including powder coating, galvanizing, anodizing, and polishing.

Contact Prime

Still unsure about custom fabrication? Let’s talk about your project today.

📞 Start your quote now:

👉 Visit: https://primecustomparts.com

📧 Email: [email protected]

From one drawing to mass production, Prime brings your ideas to life — with speed, precision, and trust.