What Is the Metal Cage of a Car?

Every modern vehicle’s safety depends on its hidden metal skeleton – what we in manufacturing call the safety cell. At our facility, we produce the stamped components that form this crucial structure.

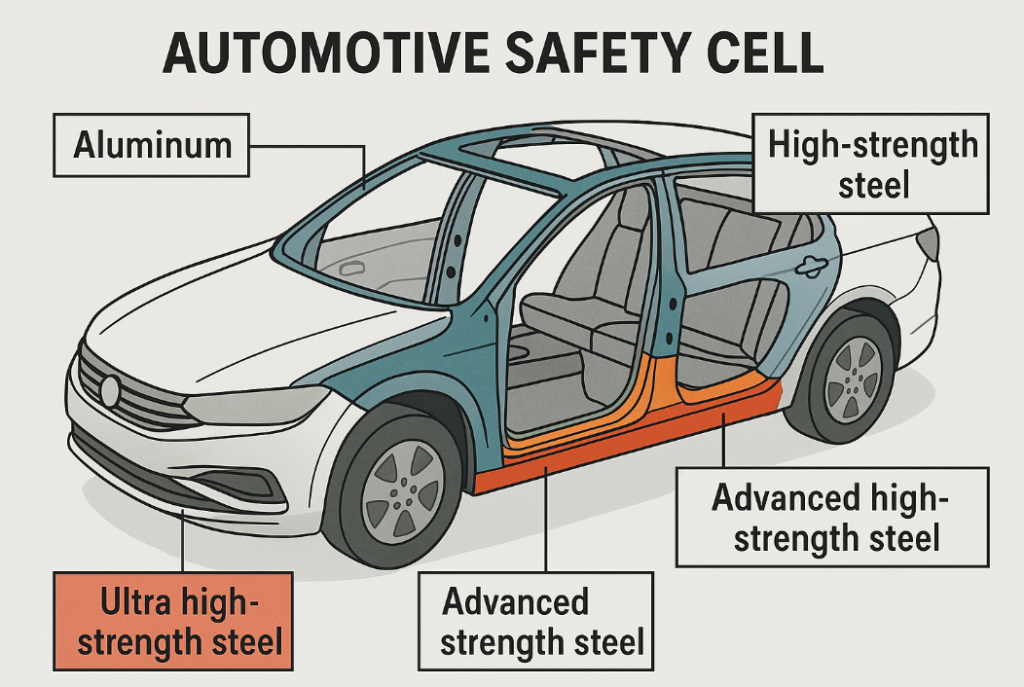

Snippet paragraph: The car’s metal cage, properly termed the "safety cell" or "passenger cage," consists of high-strength steel pillars, roof rails, and floor structures designed to maintain survival space during crashes while absorbing impact energy.

Let’s break down the components and engineering behind this life-saving structure.

LOOP_START

How Is a Car’s Safety Cell Constructed?

The passenger cage integrates multiple stamped and welded components in a carefully engineered layout.

Snippet paragraph: Modern safety cells use boron steel (up to 1500MPa yield strength) for A/B/C pillars combined with high-strength steel roof rails, creating a continuous load path that channels crash forces around the passenger compartment.

Primary Structural Elements

Vertical Components

- A-pillars (windshield supports)

- B-pillars (between doors)

- C/D-pillars (rear structure)

Horizontal Members

- Roof rail reinforcements

- Rocker panels (floor sides)

- Cross-car beams

Material Strength Distribution

| Component | Steel Grade | Thickness | Yield Strength |

|---|---|---|---|

| A-pillar | Boron 1500 | 1.8mm | 1500MPa |

| Roof rail | DP1000 | 1.2mm | 1000MPa |

| Floor pan | DP600 | 0.9mm | 600MPa |

Manufacturing Processes

- Hot stamping for ultra-high-strength components

- Laser welding for precision joints

- Hydroforming for complex tubular sections

- Adhesive bonding between layers

LOOP_END

LOOP_START

What Materials Are Used in Safety Cells?

Automakers carefully balance strength, weight and cost when selecting cage materials.

Snippet paragraph: Today’s cages combine hot-stamped boron steel (22-35% of structure), dual-phase steels (50-60%), and aluminum alloys (in premium vehicles) – with advanced joining techniques creating crash-resistant monocoque structures.

Material Composition Breakdown

Typical Mass Distribution

| Material | Usage % | Application Areas |

|---|---|---|

| Boron steel | 25% | Pillars, critical zones |

| DP600/800 | 55% | Floor, roof reinforcements |

| Aluminum | 15% | Luxury vehicle structures |

| Magnesium | 5% | Selective reinforcement |

Crash Performance Comparison

| Material | Energy Absorption | Weight Penalty | Cost Factor |

|---|---|---|---|

| Boron | Excellent | High | $$$ |

| DP steel | Good | Moderate | $$ |

| Aluminum | Very Good | Low | $$$$ |

Emerging Technologies

- 3D-printed titanium nodes for stress points

- Carbon fiber reinforcement in hybrid structures

- Self-healing coatings for corrosion protection

LOOP_END

LOOP_START

How Do Safety Standards Influence Cage Design?

Global regulations directly shape the geometry and material selection of passenger cages.

Snippet paragraph: NCAP crash tests mandate specific deformation behaviors – requiring engineered crumple zones at front/rear while maintaining <125mm survival space intrusion in side impacts, achieved through multi-layer steel construction.

Regulatory Requirements

Key Crash Test Standards

| Standard | Test Speed | Allowable Intrusion |

|---|---|---|

| FMVSS 214 | 50km/h side | <150mm |

| Euro NCAP | 64km/h frontal | <100mm footwell |

| IIHS small overlap | 64km/h | Steering column <100mm |

Design Solutions for Compliance

| Requirement | Engineering Solution |

|---|---|

| Roof crush | High-strength roof bows |

| Side impact | Door beam reinforcements |

| Pedestrian safety | Energy-absorbing structures |

Testing Validation Methods

- Computer simulation (LS-DYNA software)

- Actual crash tests (30+ sensors)

- Sectional destructive testing

LOOP_END

Conclusion

The automotive safety cell represents decades of metallurgical and engineering advancement – a carefully balanced metal cage that saves lives while meeting stringent global safety standards.