What is the Metal Stamping Process?

Problem: Many global sourcing managers face part failures, budget overruns, and long lead times because they don’t fully understand the metal stamping process.

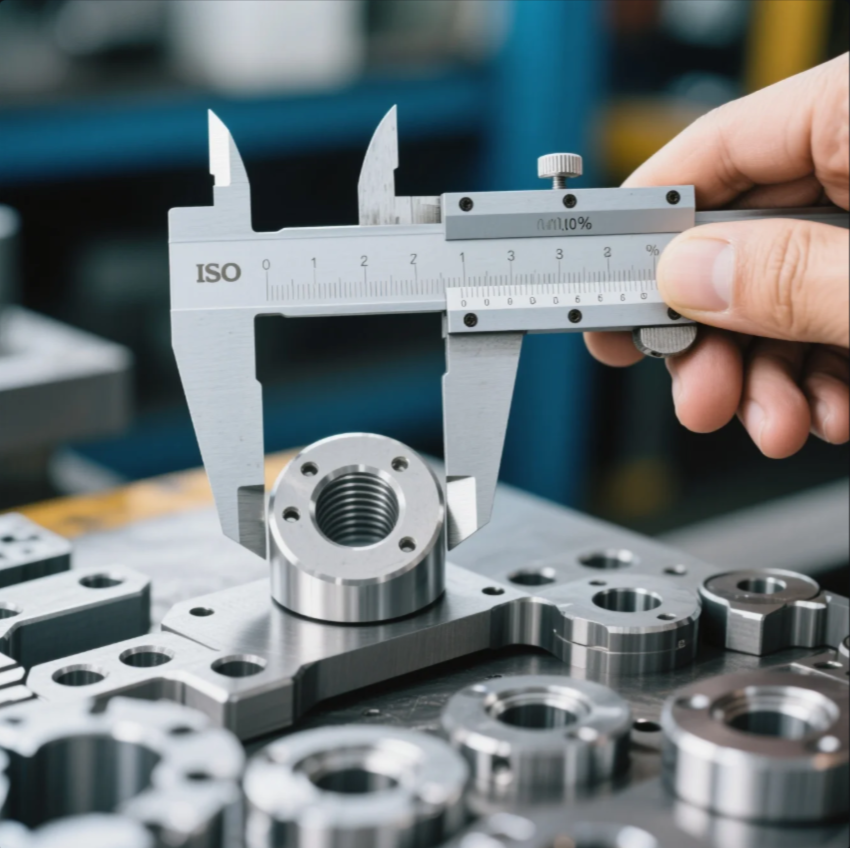

The metal stamping process is a precise, repeatable method of transforming sheet metal into engineered components using dies and mechanical or CNC-powered presses. It is the foundation for producing millions of parts used in cars, appliances, electronics, construction, and industrial equipment.

At Prime, an ISO certified metal stamping supplier, we deliver full-process support including CAD design, tooling development, press operation, QC, packaging, and logistics. With over 20 years of experience, we serve clients in over 30 countries—delivering millions of custom stamping parts annually.

What are the 7 Steps in the Stamping Method?

The metal stamping process typically follows seven essential steps. Each is critical to producing consistent, accurate, and cost-effective custom stamping parts:

| Step | Description |

|---|---|

| 1. Design | Engineers prepare 2D/3D drawings and define tolerances. |

| 2. Tooling | Dies are machined from hardened tool steel or carbide. |

| 3. Blanking | Raw metal sheets are cut to shape. |

| 4. Forming | The sheet is bent, punched, drawn, or formed by the press. |

| 5. Trimming | Unwanted edges are removed for final geometry. |

| 6. Cleaning | Deburring, degreasing, and anti-rust coating. |

| 7. Inspection | Final QC: visual check, measurement, and function test. |

Prime’s Advantages in This Process

- In-house die shop reduces tooling delays by 40%

- Standard lead time: 7–15 days from tooling to mass production

- Fully documented QC process for every batch of stamped parts

We handle small to large batches, from 100 pcs to over 1 million pcs/month, with consistent results.

What is the Stamping Procedure?

The stamping procedure refers to the actual manufacturing workflow once the part design and die tooling are ready.

Standard Stamping Procedure at Prime:

- Review technical drawings with clients

- Material selection based on function and finish (e.g. aluminum, galvanized steel)

- Precision CNC machining of die sets

- Setup of press machines and alignment calibration

- Test runs and part validation (First Article Inspection)

- Mass production using high-speed presses

- In-line and post-production inspection

- Packaging with foam, plastic wrap, and export cartons

- Shipment via sea, air, or DDP

Additional Services from Prime:

- SPC control charts for automotive buyers

- PPAP documentation (Level 3 available upon request)

- RoHS-compliant materials for European customers

- Assembly and spot welding integration

With end-to-end process integration, Prime ensures you only deal with one trusted source for the complete metal stamping process.

What is the CNC Stamping Process?

The CNC stamping process adds digital precision and control to conventional stamping. It is ideal for custom CNC stamping parts that require complex geometries, tight tolerances, or low-to-medium volumes.

| Feature | Traditional Stamping | CNC Stamping |

|---|---|---|

| Setup Time | Long | Short |

| Part Changeover | Difficult | Fast |

| Tolerances | ±0.05mm typical | ±0.01mm achievable |

| Design Flexibility | Limited | High |

| Best For | Mass runs | Custom, short-run, precision parts |

At Prime, we use CNC stamping for:

- Rapid prototyping

- Small batch production

- Electronics components

- Brackets with varied hole patterns

- Parts that evolve across product versions

Why Global Clients Prefer CNC Stamping at Prime

- Program uploads from CAD within 1 hour

- In-house validation with 3D scanners

- CNC-controlled presses up to 160 tons

- Reduced rework and scrap rate by 30%

📌 See more on our CNC stamping services »

What Are the Four Types of Metal Stamping?

Depending on the part design, material, and budget, four different metal stamping processes are typically used:

| Type | How It Works | Used For |

|---|---|---|

| Progressive Die | A strip moves through several dies with each stroke | High-speed, consistent parts like terminals, washers |

| Deep Draw | The metal is pulled into a deep cavity without tearing | Battery shells, beverage cans, instrument covers |

| Transfer Die | The part is moved across separate stations | Large parts like auto panels, HVAC units |

| Four-Slide | Dies operate from four directions simultaneously | Compact, detailed parts like clips, spring holders |

At Prime, we assess your part drawing to select the most cost-efficient and technically viable metal stamping process.

Prime’s In-House Metal Stamping Capabilities

Shandong Prime International Trade Co., Ltd. is a full-service metal stamping parts supplier in China offering:

- 10 automated press lines (including 200T, 315T, 500T capacities)

- ISO 9001 & CE certified processes

- CNC stamping, progressive die stamping, deep draw

- Quick tooling: hardened die in 7 working days

- 99.5% on-time delivery rate

We also offer surface finishing in-house:

- Zinc plating / nickel plating

- Powder coating / painting

- Deburring and tumbling

- Logo engraving or part marking

For every project, we assign an account engineer, project coordinator, and QC inspector to guarantee smooth execution.

Real Client Case Studies Using the Metal Stamping Process

Case 1 – Automotive Clip Brackets (Germany)

- Required: 1 million units/year

- Material: HSLA steel

- Process: Progressive die stamping

- Delivery: 14 days per batch

- Result: Improved yield by 22%, reduced cost by 18%

Case 2 – Medical Equipment Panel (USA)

- Required: 2000 pcs/month

- Material: Aluminum 5052

- Process: CNC stamping

- Tolerance: ±0.01mm

- Result: 100% pass rate on dimensional report

Case 3 – Stainless Steel Enclosures (France)

- Material: SS304 with satin finish

- Operation: Deep draw + trimming + spot welding

- Quantity: 5000 pcs

- Result: Delivered in 17 days with zero defect complaints

Conclusion

The metal stamping process is one of the most efficient and reliable ways to produce custom metal components at scale. Whether you need 100 parts or 1 million, choosing an experienced, certified, and responsive supplier is key.

✅ Prime provides:

- Custom stamping parts with tight tolerances

- Fast lead times and full export documentation

- End-to-end control from CAD to delivery

- Competitive pricing from a China-based facility

📞 Contact Prime Now for a Quote

Let us support your next metal stamping project—on time, on spec, and on budget.