What is the Number 1 Rule in Welding?

When it comes to welding, ensuring safety, precision, and quality is essential for any successful job. The number one rule is a fundamental aspect that every welder must prioritize to avoid risks and achieve high-quality results.

Snippet paragraph: The number one rule in welding is safety. Following safety protocols helps avoid injuries and ensures high-quality welds. Read on to discover why safety is the most critical aspect of welding.

Transition paragraph: Let’s dive into the golden rule of welding, some common welding codes, and the key priorities that every welder must focus on to succeed in the field.

What is the Golden Rule in Welding?

The golden rule in welding is safety first. This rule is simple but crucial: always prioritize your safety and the safety of others in your work environment. Welding involves high heat, sparks, and fumes that can cause serious injuries or health issues if proper precautions are not taken.

Snippet paragraph: The golden rule of welding is to always put safety first. Protect yourself and others to ensure your work environment is secure and conducive to quality welding.

Key Safety Measures for Welders

- Protective Gear: Always wear the necessary protective equipment, such as a welding helmet, gloves, fire-resistant clothing, and safety boots.

- Proper Ventilation: Ensure the area is well-ventilated to avoid inhaling harmful welding fumes.

- Inspect Equipment: Check your welding machine, cables, and protective gear for damage before starting work.

- Stay Focused: Avoid distractions while welding. Proper concentration is key to making precise, safe welds.

What is the Most Common Welding Code?

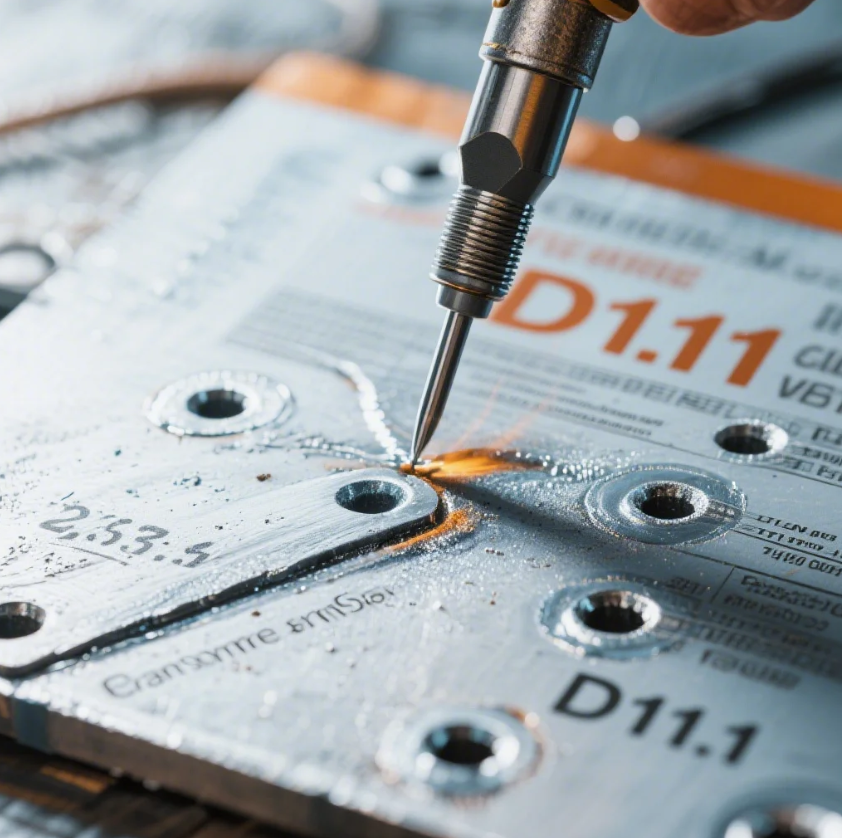

The most common welding code used worldwide is the AWS D1.1, which is part of the American Welding Society (AWS) standards. This code provides guidelines for welding in structural steel, ensuring the quality, strength, and safety of welded structures.

Snippet paragraph: The AWS D1.1 code is the most widely used welding standard, focusing on structural steel welding. It ensures the strength and safety of welded components.

Why is AWS D1.1 Important?

The AWS D1.1 code outlines essential procedures for welding, including qualification, inspection, and quality control, all of which are vital for maintaining the integrity of the welded structure. It also sets out standards for welding procedures, materials, and qualifications of welders.

Following this code is crucial for welders working in industries like construction, manufacturing, and engineering to ensure that the final product is safe, durable, and meets industry standards.

What is the Code D1.1 for Welding?

AWS D1.1 is a welding code that specifically addresses welding in structural steel. It covers a wide range of issues, including the qualification of welding procedures and personnel, the types of welding processes to be used, and the quality control methods required to ensure a reliable weld.

Snippet paragraph: The AWS D1.1 code is specifically for structural steel welding. It ensures that welds meet the required strength and safety standards for critical applications.

Key Components of AWS D1.1

- Welding Procedure Specification (WPS): Defines the parameters and settings to ensure a consistent and high-quality weld.

- Welder Qualification: Ensures that the welder has the necessary skills and qualifications to perform the welding job.

- Inspection and Testing: Specifies how welds should be inspected to ensure they meet quality standards and are free from defects.

By adhering to the AWS D1.1 code, you ensure that all welds in structural steel projects are safe, durable, and reliable.

What is the Top Priority of a Welder?

The top priority of a welder is to produce strong, high-quality welds while ensuring safety. Quality welding ensures the structural integrity of projects, while safety ensures that both the welder and others in the workspace are protected from hazards.

Snippet paragraph: A welder’s top priority is producing strong, quality welds, with safety being a close second. Both are vital to success in welding jobs.

Balancing Quality and Safety

A skilled welder must constantly balance producing high-quality welds with safety precautions. Whether it’s ensuring proper heat control, selecting the right materials, or using the correct welding technique, the goal is always to create durable and reliable welds that will stand the test of time.

Continuous Improvement and Skills Development

In addition to maintaining safety and quality, a welder’s top priority should be continuous learning. Whether it’s mastering new techniques, staying updated on welding codes, or practicing new methods, ongoing skill development is essential for long-term success in the industry.

Conclusion

In welding, the number one rule is always safety. Following safety protocols ensures a secure environment, while welding codes like AWS D1.1 ensure the quality and strength of your work. The ultimate priority for any welder is to create strong, high-quality welds while staying safe and compliant with industry standards.

Ready to improve your welding quality and safety? Contact Prime today for expert advice, custom solutions, and quick, reliable service. Get your free consultation and quote now!