What is the process of surface treatment?

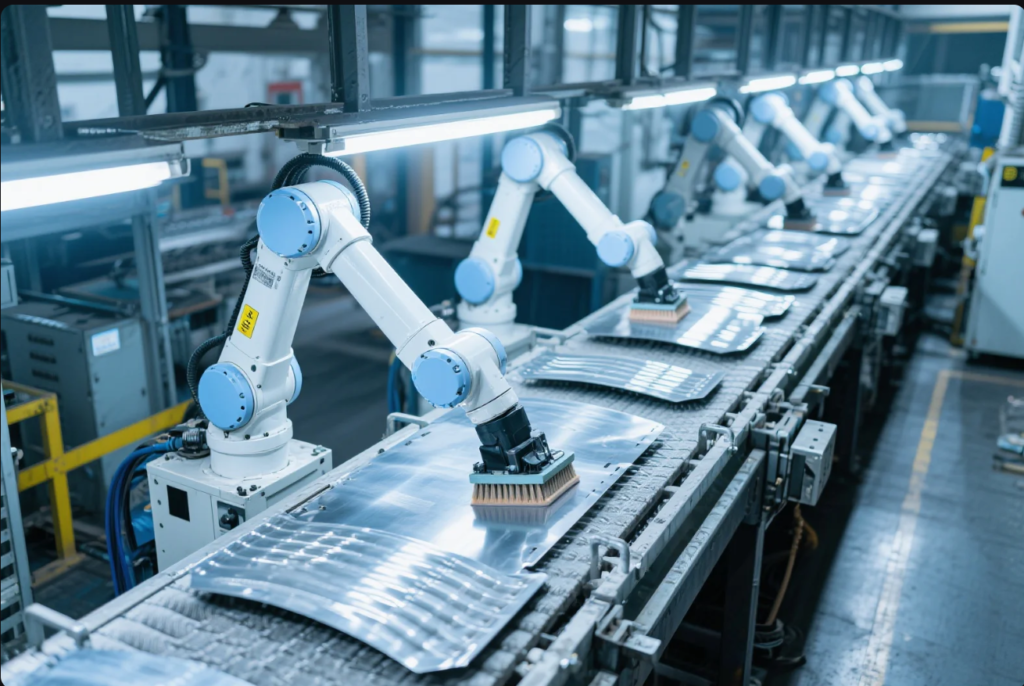

Surface treatment improves appearance, durability, and corrosion resistance of metal and plastic parts.

The process of surface treatment includes cleaning, coating, curing, and inspection. It ensures parts perform well in real-world environments.

In this article, we explain how surface treatments work, their industrial types, and why they’re essential for B2B buyers sourcing components like stamped parts, CNC parts, and plastic products.

What is the process of surface coating?

Surface coating protects parts from wear, moisture, and rust. But how is it done?

The surface coating process includes cleaning, pretreatment, applying the coating layer, and curing.

Steps involved in metal surface coating

| Step | Description |

|---|---|

| Cleaning | Removes oil, rust, or dust |

| Pretreatment | Improves coating adhesion (e.g., phosphate) |

| Coating Application | Paint, powder, or plating is applied |

| Curing | Heat or UV cures the coating |

| Final Inspection | Checks thickness, finish, durability |

Common coatings include powder coating, anodizing, electroplating, and painting. At Prime, we support custom coatings for CNC parts, stamping parts, and casting components based on your technical drawings.

What is the process of plastic surface treatment?

Plastic surfaces need special treatment to improve adhesion and appearance.

Plastic surface treatment involves cleaning, surface activation, coating, and sometimes UV curing.

Why plastics require special handling

Plastics have low surface energy, making them hard to bond or paint without treatment. That’s why surface activation methods like flame treatment, corona discharge, or plasma processing are common.

Plastic treatment steps

| Step | Description |

|---|---|

| Cleaning | Removes oil and mold release residue |

| Surface Activation | Flame, corona, or plasma treatment |

| Coating Application | Paint, print, or metallization |

| Drying/Curing | Air dry, UV curing, or thermal process |

At Prime, we treat plastic parts for better ink adhesion, color consistency, and scratch resistance. These are key for industries like automotive, electronics, and medical devices.

What are the three main categories of surface treatment?

Buyers often ask: What surface treatment should I choose for my parts?

The three main categories of surface treatment are mechanical, chemical, and electrochemical processes.

Overview of surface treatment categories

| Category | Examples | Purpose |

|---|---|---|

| Mechanical | Polishing, sandblasting | Smooth or texture the surface |

| Chemical | Phosphating, anodizing | Protect against corrosion |

| Electrochemical | Electroplating, electropolishing | Improve appearance or resistance |

Each method fits different needs. For example, sandblasting preps metal for painting, while anodizing protects aluminum parts. Prime helps clients choose the right method to balance performance and cost.

What is an example of a surface treatment?

Still wondering how it looks in action?

An example of surface treatment is powder coating, where dry powder is applied to a part and cured into a tough, decorative finish.

Why powder coating is widely used

Powder coating is popular because it’s eco-friendly, cost-effective, and durable. It doesn’t require solvents and provides a smooth, hard finish resistant to chips and chemicals.

Powder coating in use

| Industry | Typical Application |

|---|---|

| Automotive | Wheels, engine covers |

| Appliances | Oven parts, washer panels |

| Construction | Aluminum frames, railing systems |

| Industrial | Control boxes, brackets, cabinets |

At Prime, we offer powder coating in custom RAL colors. We also provide test reports for coating thickness and salt spray resistance upon request.

FAQs

Q1: Why is surface treatment important for metal parts?

It improves corrosion resistance, looks, and durability—especially for outdoor or moving parts.

Q2: Can surface treatment affect part tolerance?

Yes. Some coatings add thickness. Prime adjusts dimensions before coating to meet final tolerances.

Q3: What surface treatments do you offer?

Powder coating, anodizing, painting, electroplating, sandblasting, phosphating, and more.

Q4: Do you support RoHS-compliant coatings?

Yes. We offer RoHS and REACH-compliant options for EU export.

Q5: Can you provide salt spray test reports?

Absolutely. We offer full coating inspection and documentation for industrial clients.

Conclusion

The surface treatment process varies by material and use—but every treatment adds value. Choose methods based on function, cost, and part design.

Contact Us

Need custom surface treatment for metal or plastic parts?

✅ ISO-certified processes

✅ Color, texture, and corrosion protection options

✅ Full reports and testing available

🔗 Website: https://primecustomparts.com/

📧 Email: [email protected]

Contact Prime today for surface-finished parts that meet your specifications and global standards.