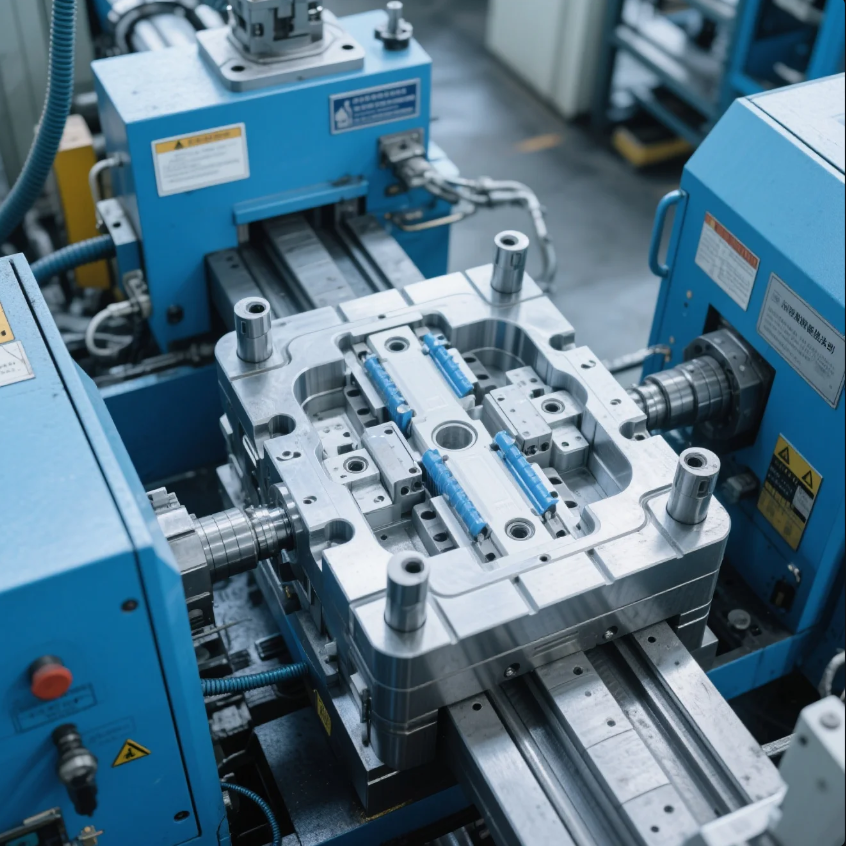

What Is the Rule of Thumb for Injection Molding?

Struggling to control cost and precision in plastic part production?

The rule of thumb in injection molding: design for manufacturability, use the right machine size, and match tolerances to function.

Many buyers face quality issues or overspending due to poor planning. Knowing key guidelines helps you save money, reduce cycle time, and avoid costly rework.

How Do You Calculate Injection Molding Cost?

Worried about budgeting your production project?

Injection molding cost is calculated based on mold tooling, part material, machine time, and labor.

Basic cost structure

| Cost Component | Typical Range |

|---|---|

| Mold Tooling | \$2,000 – \$100,000+ |

| Material Cost | \$1 – \$5 per kg (varies by resin) |

| Machine Time | \$30 – \$100 per hour |

| Labor & Overhead | Depends on region and volume |

At Prime, we help clients control these costs with efficient tooling solutions and bulk material sourcing. When clients order custom plastic injection parts, we offer detailed quotations that break down each cost clearly.

What Is the General Tolerance for Injection Molding?

Worried about part fit and performance?

The general tolerance for injection molded parts is ±0.1 mm, but can go tighter with proper design and materials.

Tolerance standards

| Feature Type | Typical Tolerance Range |

|---|---|

| Standard dimensions | ±0.1 mm |

| Critical interfaces | ±0.05 mm or tighter |

| Wall thickness | ±10% of nominal thickness |

At Prime, we provide tight tolerance injection molding services using high-precision molds and electric machines. Our QC team checks every batch using digital calipers and CMM tools, especially for clients in medical and electronics industries.

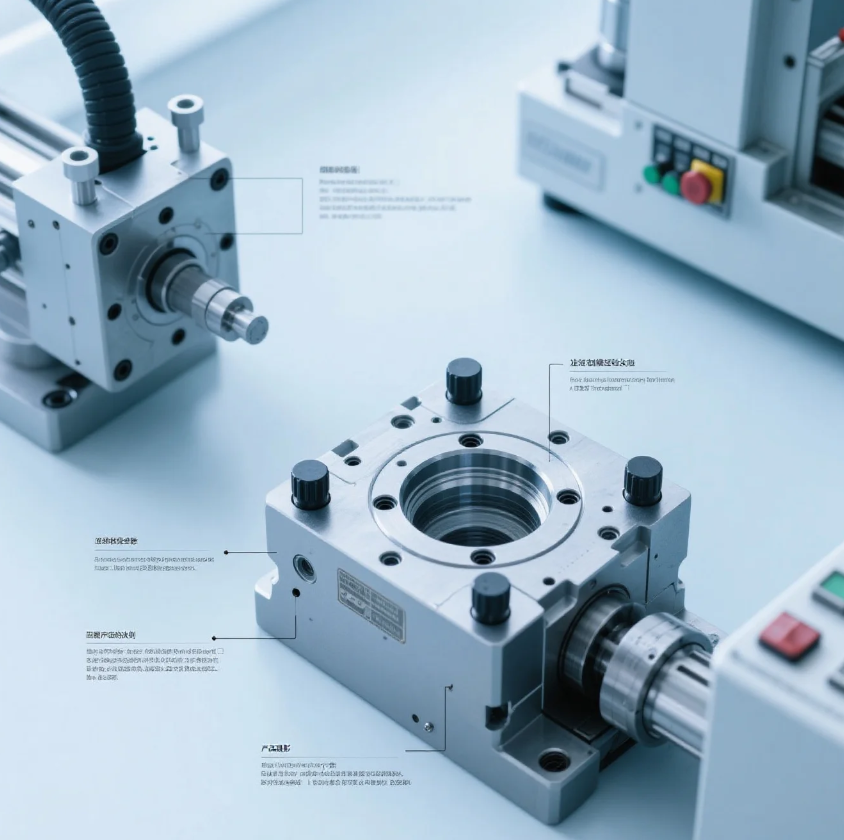

Who Makes the Best Injection Molding Machines?

Unsure which machine ensures the best output?

Top brands include Engel, Arburg, Haitian, and Sumitomo. Each offers unique strengths for different applications.

Machine comparison by brand

| Brand | Known For |

|---|---|

| Engel | All-electric precision and automation |

| Arburg | Flexible setups for small parts |

| Haitian | Best value for mid-to-high volume production |

| Sumitomo | Speed and energy efficiency in electric machines |

At Prime, we use Haitian hybrid machines for high output and Engel electric models for micro-tolerance parts. This mix gives our customers consistent results with each production run.

How Do I Know What Size Injection Molding Machine I Need?

Worried about under- or over-sizing your equipment?

You calculate machine size based on shot weight, clamping force, and mold dimensions.

Sizing guide

| Factor | Rule of Thumb |

|---|---|

| Shot size | 20–80% of machine’s max shot capacity |

| Clamping force | 2–8 tons per square inch of projected area |

| Mold size | Should fit within machine platen dimensions |

At Prime, we assist clients by matching their product design with the right machine type. Whether you’re producing large plastic enclosures or micro connectors, we align tooling, machine, and materials to ensure efficiency and precision.

Conclusion

Follow proven rules for cost, tolerance, and machine sizing to get the best molding results.

Contact Prime now for a free quote and project consultation.

We offer support from mold design to final product, with fast delivery and ISO-certified quality for global buyers.